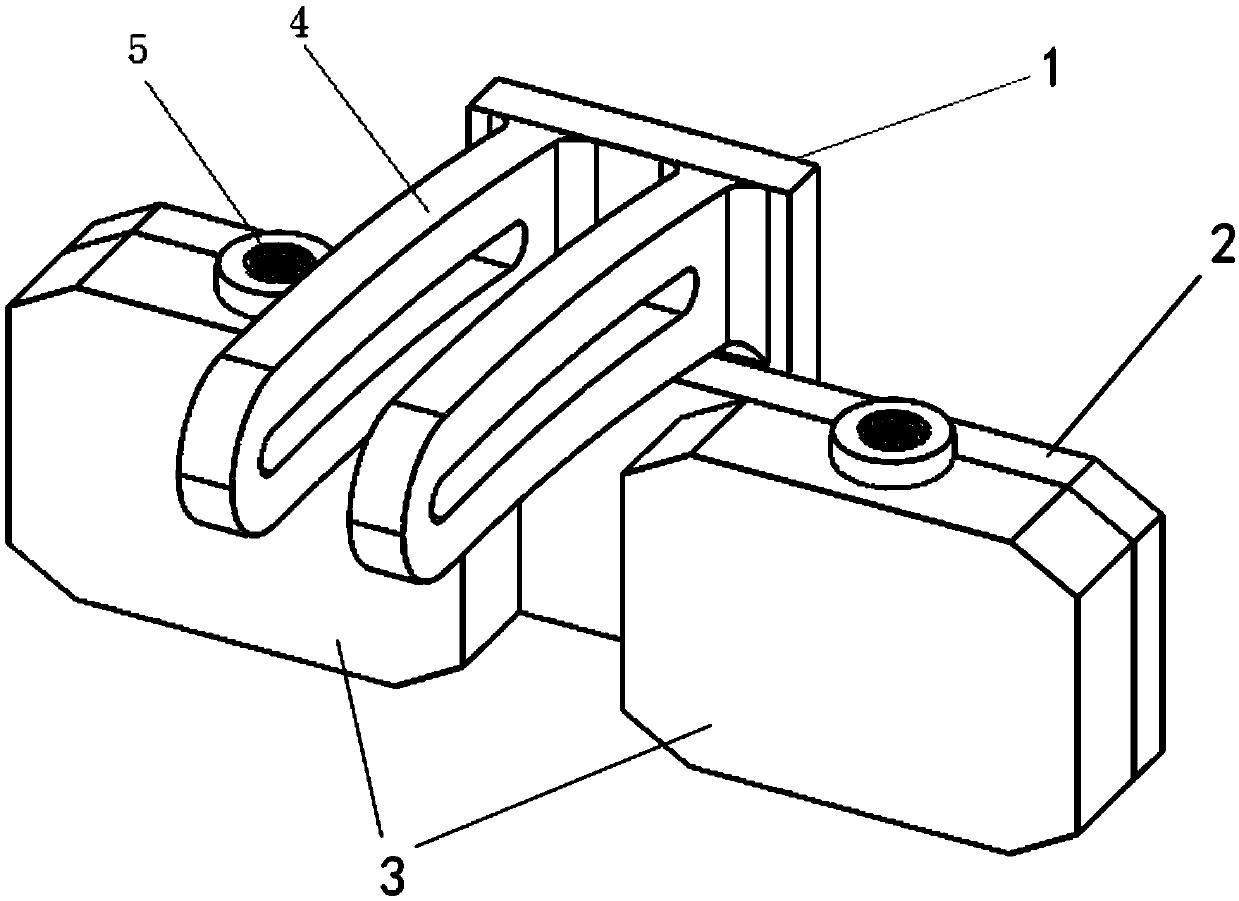

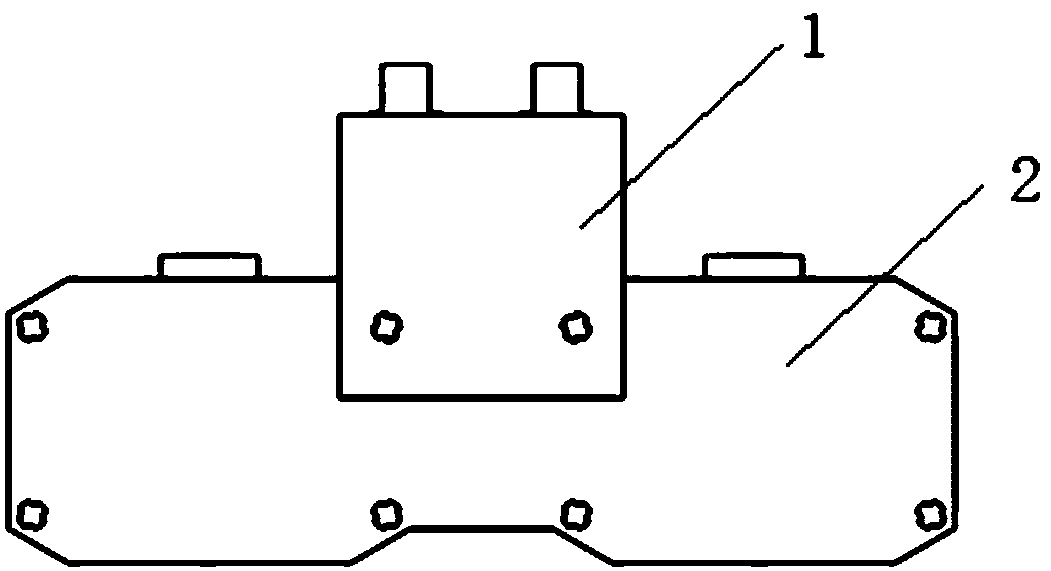

A titanium alloy surfacing gas shield fixed to a welding torch

A technology of titanium alloy and protective cover, which is applied in the direction of welding/welding/cutting objects, devices for supplying/expelling shielding gas, welding equipment, etc. Effect and other problems, to achieve good protection effect, obvious gas protection effect, and improve the insufficient effect of gas path protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

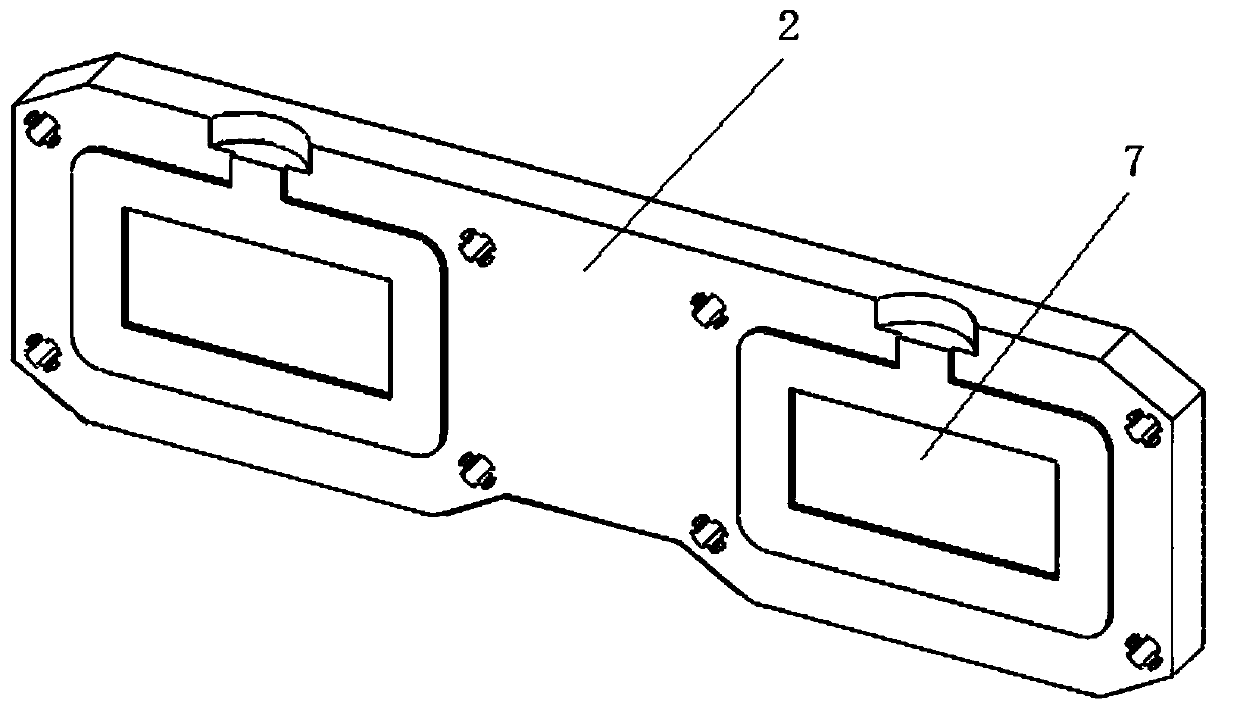

[0030] This embodiment is basically the same as Embodiment 1. The width of the "back"-shaped groove of the first air circuit 6 is 10mm, which is 1.5mm wider than the width of the "back"-shaped bump of the second air circuit 7. The first air circuit The depth of the "back"-shaped groove of the circuit 6 is 10mm, the height of the "back"-shaped protrusion of the second air circuit circuit 7 is 5mm, and the fan-shaped opening angle of the fan-shaped gas ejection hole at the bottom of the front cover 3 is 110°.

Embodiment 3

[0032] This embodiment is basically the same as Embodiment 1. The width of the "back"-shaped groove of the first air circuit 6 is 10 mm, which is 0.5 mm wider than the width of the "back"-shaped bump of the second air circuit 7. The first air circuit The depth of the "back"-shaped groove of the circuit 6 is 15mm, the height of the "back"-shaped protrusion of the second air circuit circuit 7 is 5mm, and the fan-shaped opening angle of the fan-shaped gas ejection hole at the bottom of the front cover 3 is 130°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com