Preparation method for natural fiber-containing car trim and application thereof

A technology for natural fiber and automobile decoration, which is applied to the preparation and application field of automobile decoration parts containing natural fibers, can solve the problems of poor air permeability, poor recyclability, and low strength of all-plastic automobile decoration parts, and achieves saving of raw materials and good quality. Breathability, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

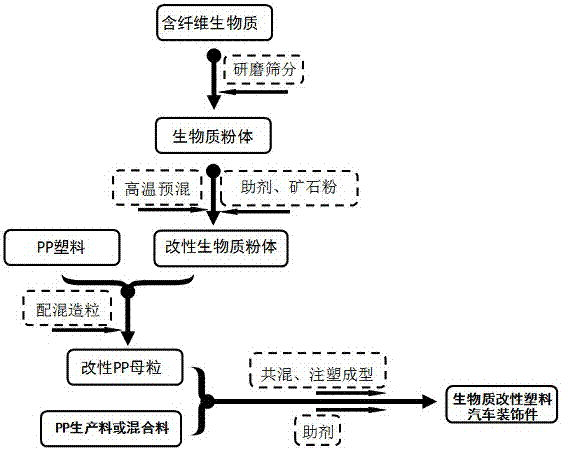

[0023] The preparation method of the modified car trim containing natural fibers specifically comprises the following steps:

[0024] (1) Prepare raw materials: Weigh raw materials according to the proportion: 8% of tea stem powder, 7% of 600 mesh carbon powder, 3% of additive styrene-maleic anhydride copolymer, 5% of other additives, 15% of 800 mesh calcium carbonate powder %, PP material 63%, stand-by;

[0025] (2) Preparation of biomass powder: Grinding the biomass tea stem powder containing natural fibers through a ball mill with a particle size of 400 mesh, and drying to obtain biomass powder;

[0026] (3) Modification of biomass powder: put the biomass powder prepared in the step (2) into a high mixer, add additives and ore powder at the same time, pre-mix in the high mixer, and Heating and drying, the heating temperature is 70°C, and the heating time is 15 minutes to obtain modified biomass powder;

[0027] (4) Compounding and granulation: the modified biomass powder ...

Embodiment 2

[0031] The preparation method of the modified car trim containing natural fibers specifically comprises the following steps:

[0032] (1) Prepare raw materials: Weigh raw materials according to proportion: poplar wood powder 11%, 800 mesh carbon powder 4%, silane coupling agent 3%, 600 mesh calcium carbonate powder 19%, PP material 56.5%, other additives 6.5% ,stand-by;

[0033] (2) Preparation of biomass powder: the biomass poplar wood powder containing natural fibers is pulverized by a ball mill with a particle size of 120 mesh, and dried to obtain biomass powder;

[0034] (3) Modification of biomass powder: put the biomass powder prepared in the step (2) into a high mixer, add additives and ore powder at the same time, pre-mix in the high mixer, and Heating and drying, the heating temperature is 100°C, and the heating time is 12 minutes to obtain modified biomass powder;

[0035] (4) Compounding and granulation: the modified biomass powder obtained in the step (3) and pol...

Embodiment 3

[0039] The preparation method of the modified car trim containing natural fibers specifically comprises the following steps:

[0040] (1) Prepare raw materials: Weigh raw materials in proportion: rice bran 20%, 800 mesh carbon powder 10%, silane coupling agent 2%, 700 mesh calcium carbonate powder 10%, PP material 51%, other additives 7%, wait for use;

[0041] (2) Preparation of biomass powder: Grinding the biomass rice bran containing natural fibers through a ball mill with a particle size of 500 mesh, and drying to obtain biomass powder;

[0042] (3) Modification of biomass powder: put the biomass powder prepared in the step (2) into a high mixer, add additives and ore powder at the same time, pre-mix in the high mixer, and Heating and drying, the heating temperature is 120°C, and the heating time is 13 minutes to obtain modified biomass powder;

[0043] (4) Compounding and granulation: the modified biomass powder obtained in the step (3) and polypropylene (PP) are compound...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com