Structural color ink and preparation method thereof

A technology of structural color and ink, applied in ink, home appliances, applications, etc., can solve problems such as lack of color and vividness of text patterns, harm to the human body and the environment, and reduce friction resistance, etc., to achieve abundant reserves, environmental friendliness, The effect of ensuring the stability of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Disperse silicon dioxide nano-microspheres with a particle diameter of 120 nm in water to prepare a silicon dioxide aqueous dispersion with a mass fraction of 4%.

[0027] Prepare an aqueous gelatin solution with a mass fraction of 4%, and then mix 2ml of the above-mentioned silica aqueous dispersion with 3ml of the above-mentioned gelatin aqueous solution to obtain a structural color ink. At this time, the mass ratio of silica microspheres to gelatin is 2:3. Then use a pipette to absorb a small amount of structural color ink, draw a pattern on the substrate, and place it in an oven to dry.

Embodiment 2

[0029] Disperse silicon dioxide nano-microspheres with a particle diameter of 150 nm in water to prepare a silicon dioxide aqueous dispersion with a mass fraction of 4%.

[0030] Prepare a gelatin aqueous solution with a mass fraction of 4%, and then mix 2ml of the above-mentioned silica aqueous dispersion with 3ml of the above-mentioned gelatin aqueous solution to obtain a structural color ink. At this time, the mass ratio of silica microspheres to gelatin is 2:3. Then use a pipette to absorb a small amount of structural color ink, draw a pattern on the substrate, and place it in an oven to dry.

Embodiment 3

[0032] Disperse silicon dioxide nano-microspheres with a particle diameter of 180 nm in water to prepare a silicon dioxide aqueous dispersion with a mass fraction of 4%.

[0033] Prepare a gelatin aqueous solution with a mass fraction of 4%, and then mix 2ml of the above-mentioned silica aqueous dispersion with 3ml of the above-mentioned gelatin aqueous solution to obtain a structural color ink. At this time, the mass ratio of silica microspheres to gelatin is 2:3. Then use a pipette to absorb a small amount of structural color ink, draw a pattern on the substrate, and place it in an oven to dry.

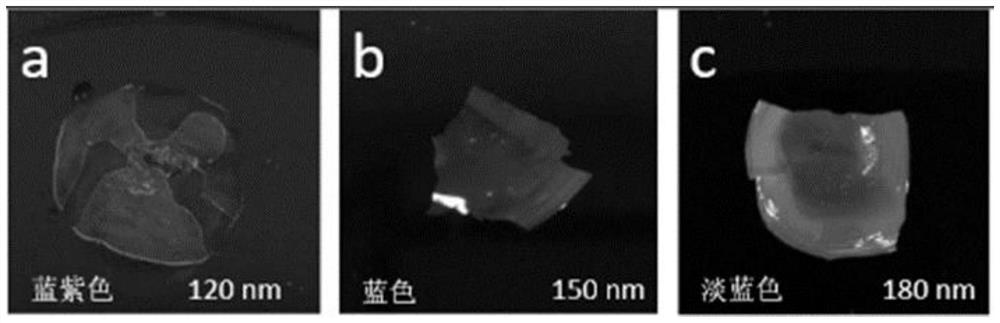

[0034] figure 1 Be the optical photograph of the ink prepared in embodiment 1-3 after drying, figure 1 a corresponds to embodiment 1, figure 1 b corresponds to embodiment 2, figure 1 c corresponds to Example 3. From left to right, the colors are blue-violet, blue and light blue, indicating that changing the particle size of silica nanospheres can form a microstructure that can c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com