Environment-friendly paint

An environmentally friendly, water-based polyurethane technology, applied in the field of chemical coatings, can solve the problems of low disposable dry film thickness, high cost, poor water and alcohol resistance, and achieve good alcohol and abrasion resistance, good moldability, and good environmental protection. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

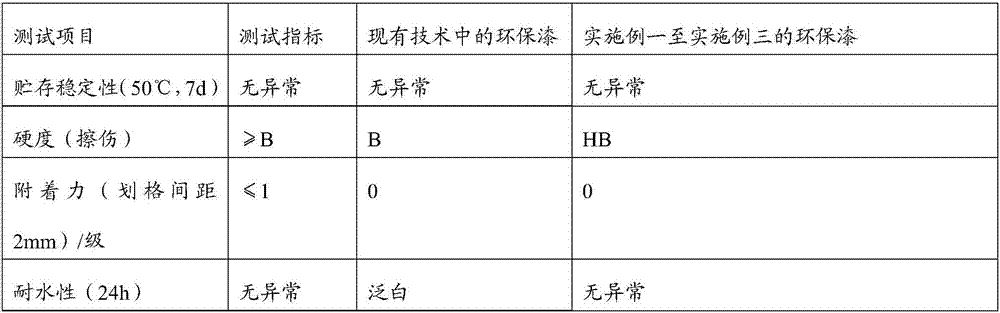

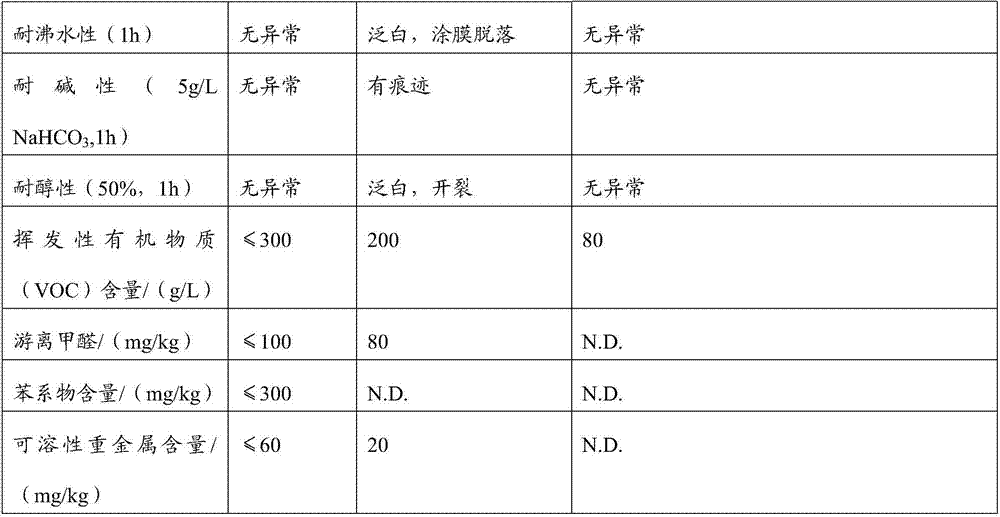

Examples

Embodiment 1

[0030] An environmentally friendly paint, prepared from the following raw materials in parts by weight: 20 parts of water-based resin, 2 parts of dye auxiliaries, 40 parts of water, 0.3 parts of LT rheological additive, 0.5 part of WT-204 rheological additive, film-forming auxiliary 3 parts, the water-based resin includes water-based polyurethane resin emulsion and water-based alkyd resin, the weight ratio of the water-based polyurethane resin emulsion and water-based alkyd resin is 1:1. The film-forming aid is a mixture of diethylene glycol butyl ether and dipropylene glycol butyl ether, and the weight ratio of diethylene glycol butyl ether to dipropylene glycol butyl ether is 3.3:1.

[0031] Described water-based polyurethane resin emulsion is the mixed solution that model is the water-based polyurethane resin emulsion of KT200 and the water-based polyurethane resin emulsion of KT803, and the model is that the water-based polyurethane resin emulsion of KT200 and the model are...

Embodiment 2

[0034] An environmentally friendly paint, prepared from the following raw materials in parts by weight: 32 parts of water-based resin, 5 parts of dye auxiliaries, 65 parts of water, 3 parts of LT rheological additives, 0.7 parts of WT-204 rheological additives, film-forming auxiliary 3-5 parts of agent, the water-based resin includes water-based polyurethane resin emulsion and water-based alkyd resin, the weight ratio of the water-based polyurethane resin emulsion and water-based alkyd resin is 1:1. The film-forming aid is a mixture of diethylene glycol butyl ether and dipropylene glycol butyl ether, and the weight ratio of diethylene glycol butyl ether to dipropylene glycol butyl ether is 3.8:1.

[0035] Described water-based polyurethane resin emulsion is the mixed solution that model is the water-based polyurethane resin emulsion of KT200 and the water-based polyurethane resin emulsion of KT803, and the model is that the water-based polyurethane resin emulsion of KT200 and t...

Embodiment 3

[0038]An environmentally friendly paint, prepared from the following raw materials in parts by weight: 28 parts of water-based resin, 3 parts of dye additives, 50 parts of water, 0.3 parts of LT rheology additive, 0.6 parts of WT-204 rheology additive, film-forming aid 3-5 parts of agent, the water-based resin includes water-based polyurethane resin emulsion and water-based alkyd resin, the weight ratio of the water-based polyurethane resin emulsion and water-based alkyd resin is 1:1. The film-forming aid is a mixture of diethylene glycol butyl ether and dipropylene glycol butyl ether, and the weight ratio of diethylene glycol butyl ether to dipropylene glycol butyl ether is 3.5:1.

[0039] Described water-based polyurethane resin emulsion is the mixed solution that model is the water-based polyurethane resin emulsion of KT200 and the water-based polyurethane resin emulsion of KT803, and the model is that the water-based polyurethane resin emulsion of KT200 and the model are th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com