Electrolytic refining system and method for crude copper with high precious metal content

An electrolytic refining and precious metal technology, applied in the electrolytic process, electrolytic components, electrodes, etc., can solve the problems of affecting the quality of the cathode copper plate, easily falling to the cathode copper plate, and precious metal loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

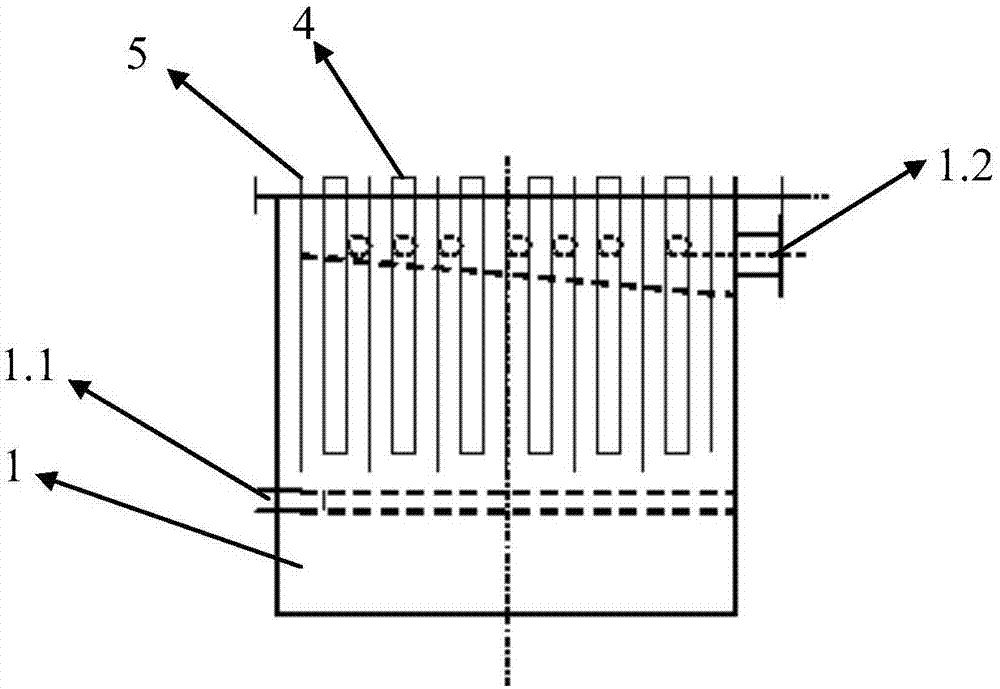

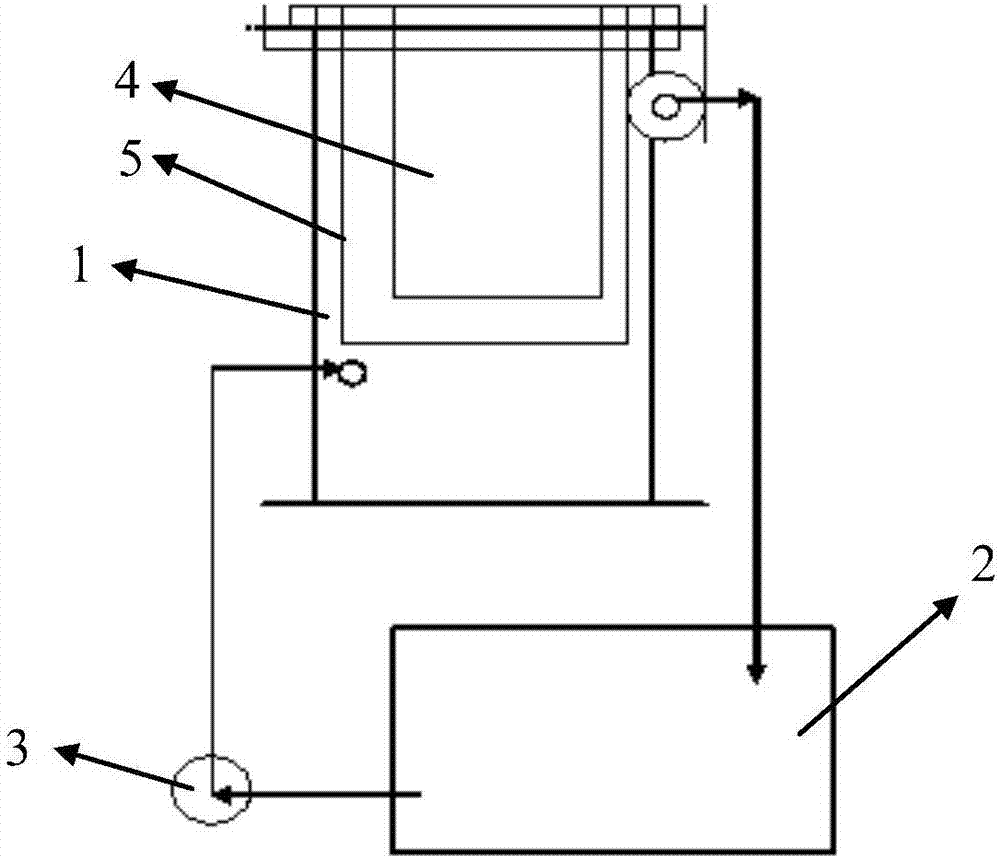

[0031] A blister copper electrolytic refining system with high precious metal content, comprising:

[0032] An electrolytic cell 1 for containing industrial electrolyte, a liquid inlet 1.1 is provided below the electrolytic cell 1, an overflow port 1.2 is provided above the electrolytic cell 1, and the liquid inlet 1.1 and the overflow port 1.2 are set opposite to the electrolytic cell 1 On the two side walls of the tank, the industrial electrolyte flows into the electrolytic cell 1 through the liquid inlet 1.1, and flows out of the electrolytic cell through the overflow port 1.2.

[0033] The electrolyte lower tank 2 is located below the electrolytic tank 1 and communicates with the liquid inlet 1.1 and the overflow port 1.2 of the electrolytic tank respectively, and a circulation pump 3 is provided between the lower electrolyte tank 2 and the liquid inlet 1.1 of the electrolytic tank, The circulating pump 3 is used to directly pump the electrolyte in the electrolyte lower ta...

Embodiment 2

[0038] A blister copper electrolytic refining method with high precious metal content, the blister copper to be refined is set as at least one anode, the anode is in contact with the electrolyte, and an anode bag is provided outside the anode; at least one cathode is in contact with the electrolyte, and the anode It is set in the same electrolytic cell as the cathode. There is a liquid inlet below the electrolytic cell and an overflow port above the electrolytic cell. The liquid inlet and overflow are set on the two opposite side walls of the electrolytic cell. Industrial The electrolyte flows into the electrolytic cell from the liquid inlet, and flows out of the electrolytic cell from the overflow port. There is a circulating pump between the liquid inlets of the tank, which is used to pump the electrolyte in the lower tank of the electrolyte directly into the electrolytic tank, and the current density during the electrolysis process is 600-1000A / m 2 , The electrolyte in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com