Efficient sewage pumping station constructed by municipality

A sewage lifting and high-efficiency technology, used in pumps, buildings, pump control, etc., can solve problems such as increasing work difficulty, inability to discharge system water, and reducing the service life of sewage pumps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

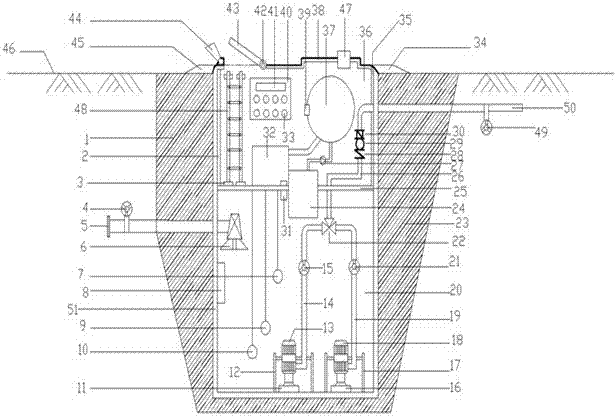

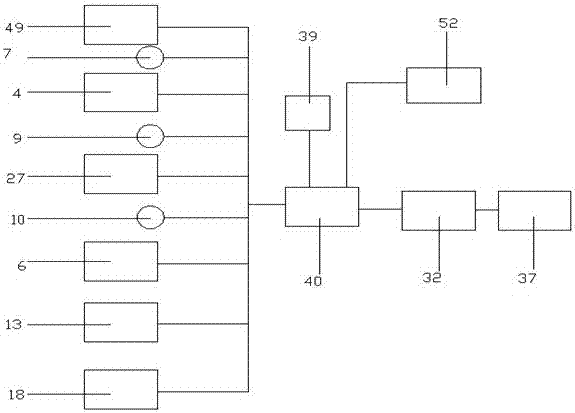

[0018] High-efficiency sewage lifting pump station for municipal construction, characterized in that it includes a main body 51, a first underground wall 1, a water inlet pipe 5, a first electric valve 4, a cutting pump 6, a first liquid level alarm 7, and a second liquid level alarm Device 9, third liquid level alarm 10, main pump 13, backup pump 18, second underground wall 23, main pump coupling device 11, backup pump coupling device 16, second electric valve 29, drain pipe 50, control cabinet 40. Biogas generator 32, biogas collection tank 37, first warehouse body 20, second warehouse body 36 and ground 46; the main body 51 is arranged underground, respectively connected to the first underground wall body 1 and the second underground wall body 23 Fixedly connected, the main body 51 is respectively connected with the water inlet pipe 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com