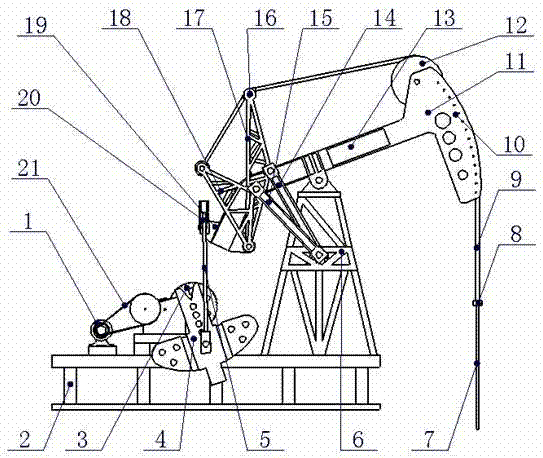

Long-stroke oil pumping unit with stack-up pull rods arranged on rear portion

A pumping unit, long-stroke technology, which is used in the production of fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of low installed capacity, large reversing impact load wire rope, low reliability, etc., and achieves improved stroke. The effect of length and fullness factor, improving work efficiency and increasing versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention and are not intended to limit the invention.

[0015] The rear stacked tie-rod long-stroke pumping unit of the present invention includes a motor 1, a support base plate 2, a gear reducer 3, a crank 4, a connecting rod 5, a tower 6, a sucker rod 7, and a rope lock 8 , traction rope 9, roller 10, donkey head 11, front fixed pulley 12, beam 13, beam balance counterweight 19, live frame 20, belt 21. The rear arm of the traveling beam 13 is provided with a triangular pendulum type pull rod, and the triangular pendulum type pull rod has a first fulcrum, a second fulcrum and a central fulcrum, and the first fulcrum and the second fulcrum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com