High-speed labor-saving steam engine

An engine and high-speed technology, applied in the direction of machines/engines, non-variable engines, mechanical equipment, etc., can solve the problems of no labor-saving transmission structure, damage to the natural environment, and non-concentrated thrust, and achieve huge commercial development value and easy Manufacturing, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

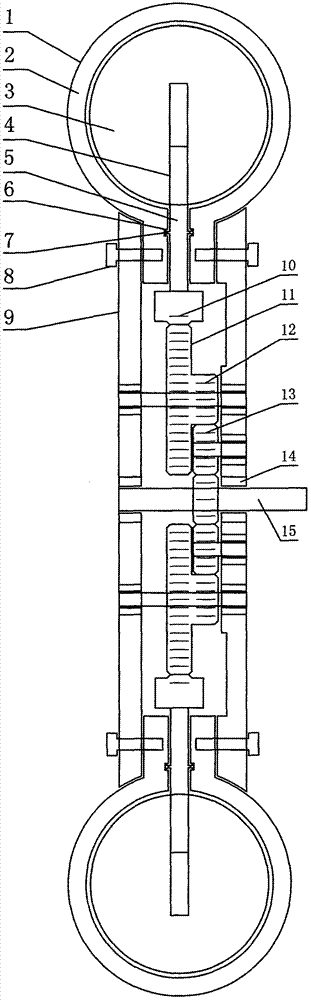

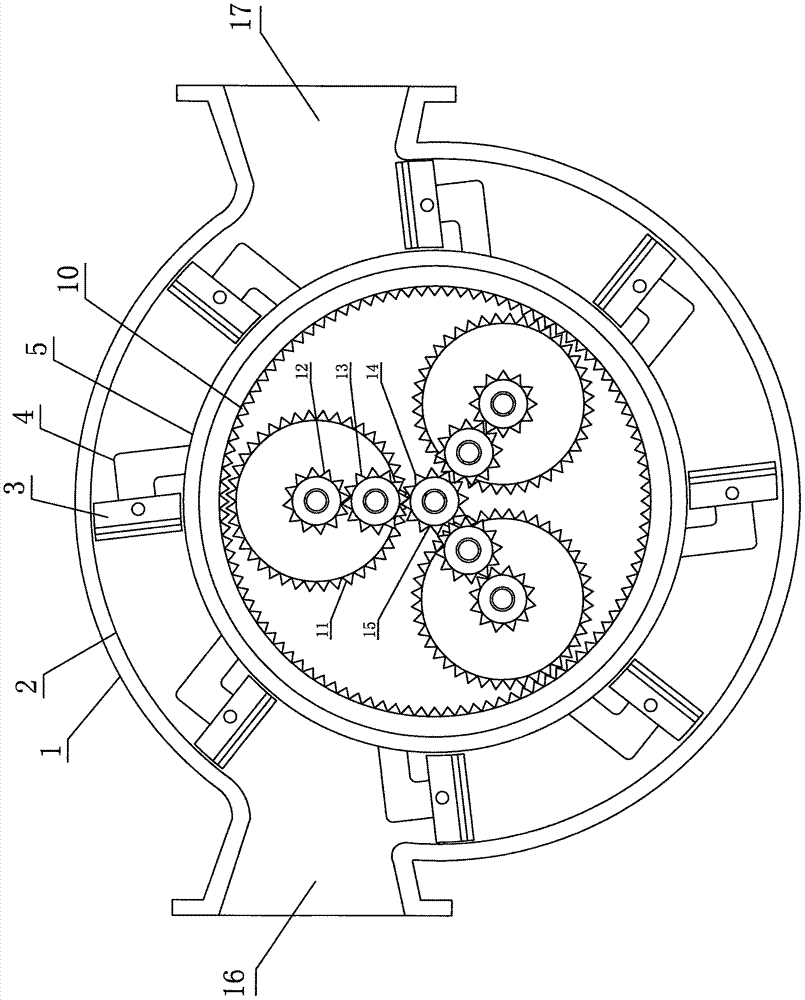

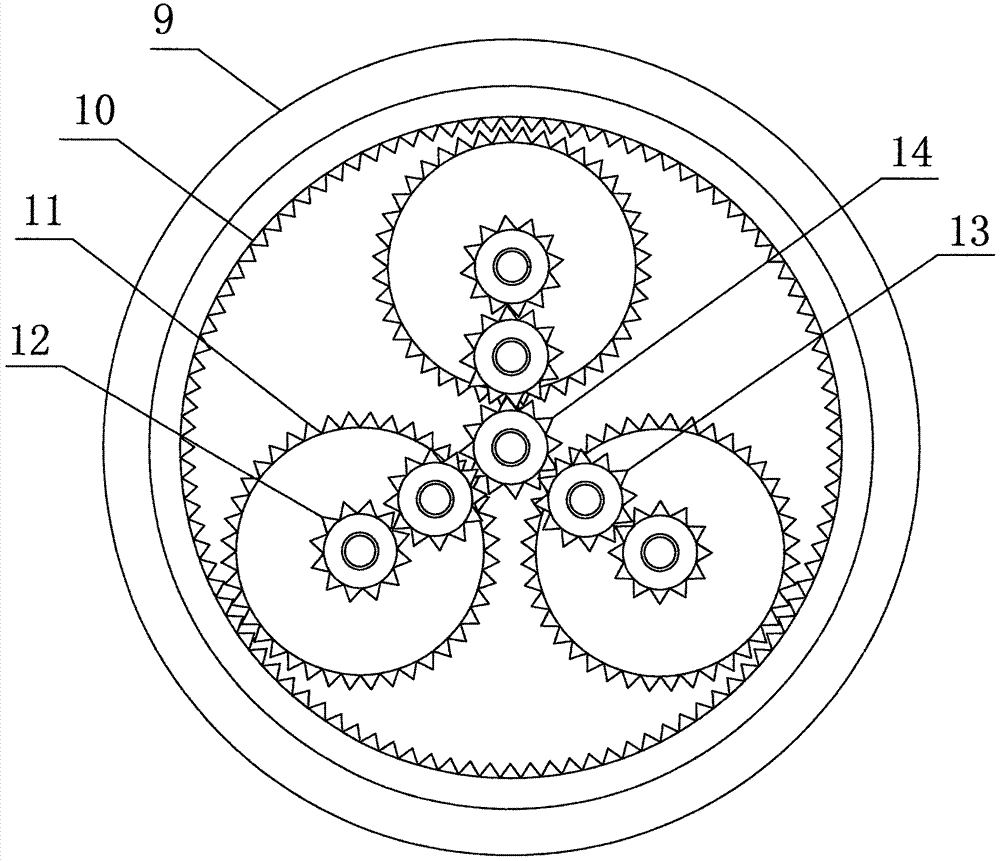

[0011] Such as figure 1 , 2 , Shown in 3: a piston-wheel type high-speed labor-saving steam engine, which includes a housing 1, an annular cylinder 2, a piston 3, a lever 4, a sealing ring 5, a concave groove 6, an inflatable sealing ring 7, and a screw nut 8. Sealing cover 9, ring gear 10, lever gear 11, 12, connecting gear 13, main shaft gear 14, bearing 15, air inlet 16, exhaust port 17, steam pipe, valve, computer, wire, instrumentation and electronics The switch, the ring gear 10 and the sealing ring 5 are integrated, and have the function of a flywheel. The ring gear 10 is matched with the lever gear large gear 11. The combination of the ring gear 10, the lever gears 11, 12, the connecting gear 13 and the main shaft gear 14 is labor-saving Speed changer, it has the function of labor saving, energy saving and speed change, the diameter of ring gear 10 is 2 times or 3 times of the diameter of lever gear bull gear 11, lever gear 11, 12 is made up of bull gear 11 and pini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com