Molten steel composition continuous detection system and method

A detection system and technology for molten steel composition, applied in the field of continuous detection system of molten steel composition, can solve the problems of low detection accuracy and hit rate of chemical composition and content, large investment and maintenance workload of detection equipment, etc., and achieve low equipment investment and compact design. , the effect of reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

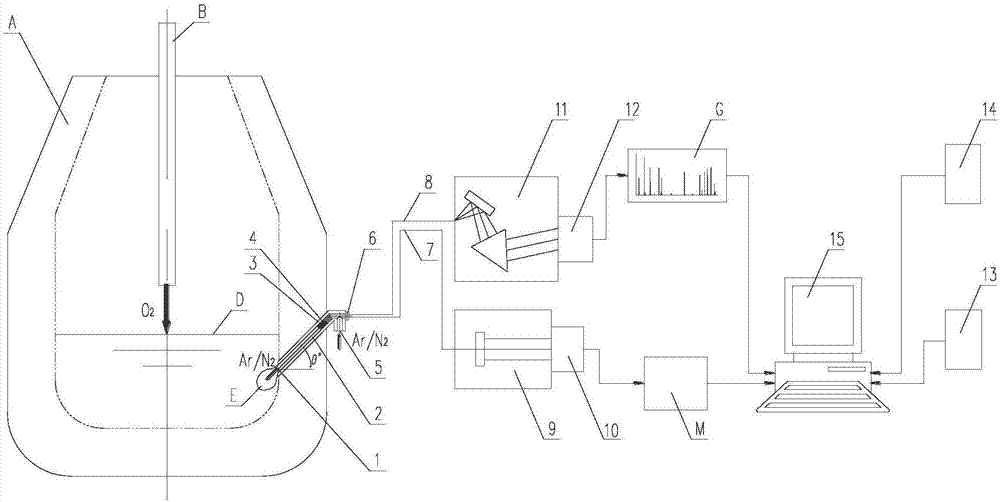

[0027] Example, figure 1 A continuous detection system for molten steel composition, mainly composed of detection nozzle 1, detection probe 2, light source probe I3, light source probe II4, inert gas injection inlet 5, optical fiber cable interface 6, optical fiber cable I7, optical fiber cable II8, light source Receiver 9, industrial camera I10, spectrometer 11, industrial camera II12, temperature database 13, element database 14 and measurement computer 15 are composed.

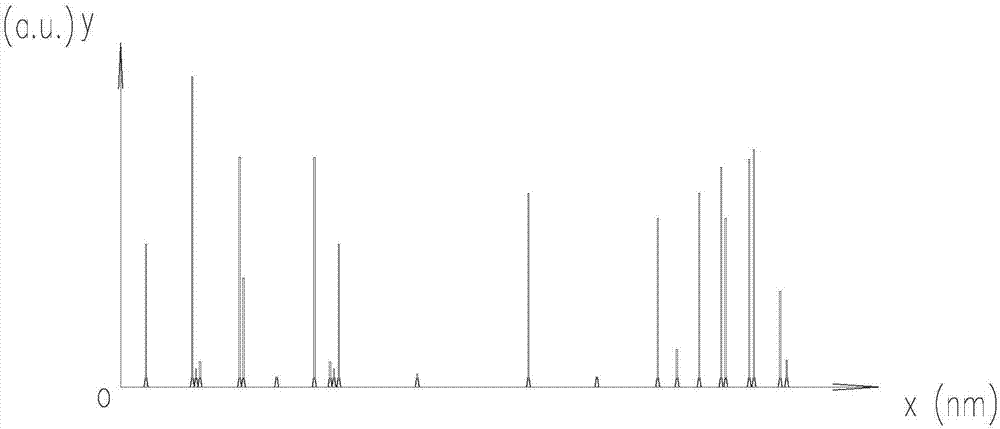

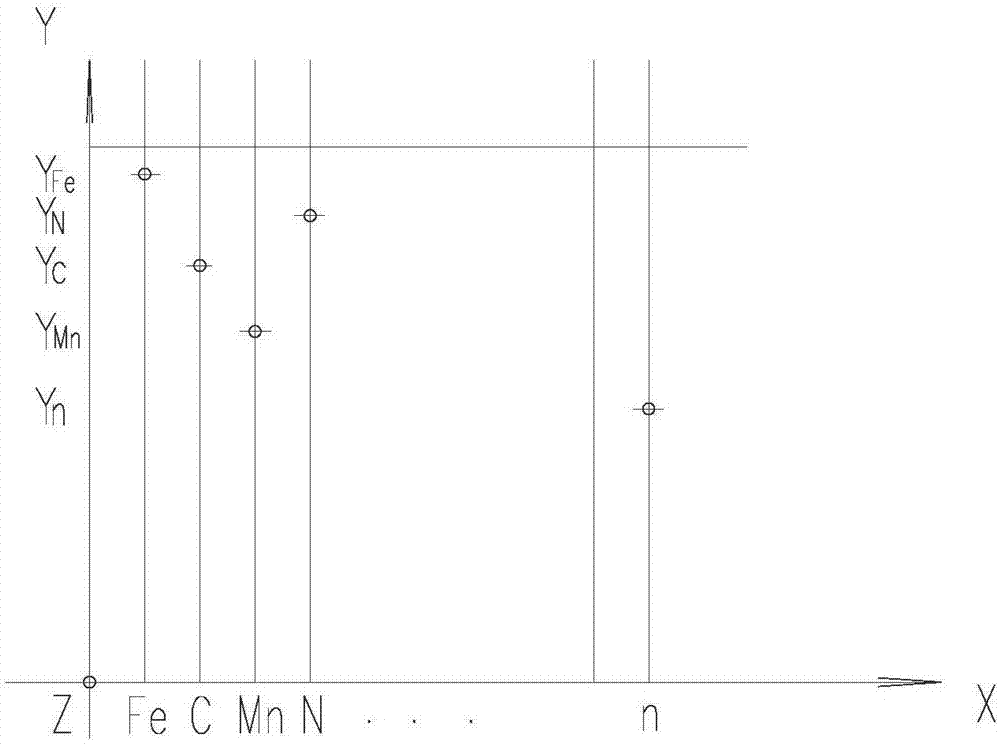

[0028] figure 1 Among them, A is the furnace body of the steelmaking converter, and B is the oxygen blowing (O 2 ) oxygen lance, D is the molten steel surface, E is the molten steel light source, θ is the inclination angle between the detection probe 2 and the molten steel surface D, Ar / N 2 is an inert gas, G is the atomic recombination spectrum, and M is the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com