Press ring and semiconductor processing device

A processing equipment and semiconductor technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as wafer deposition, and achieve the effect of improving process results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order for those skilled in the art to better understand the technical solutions of the present invention, the pressure ring and semiconductor processing equipment provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

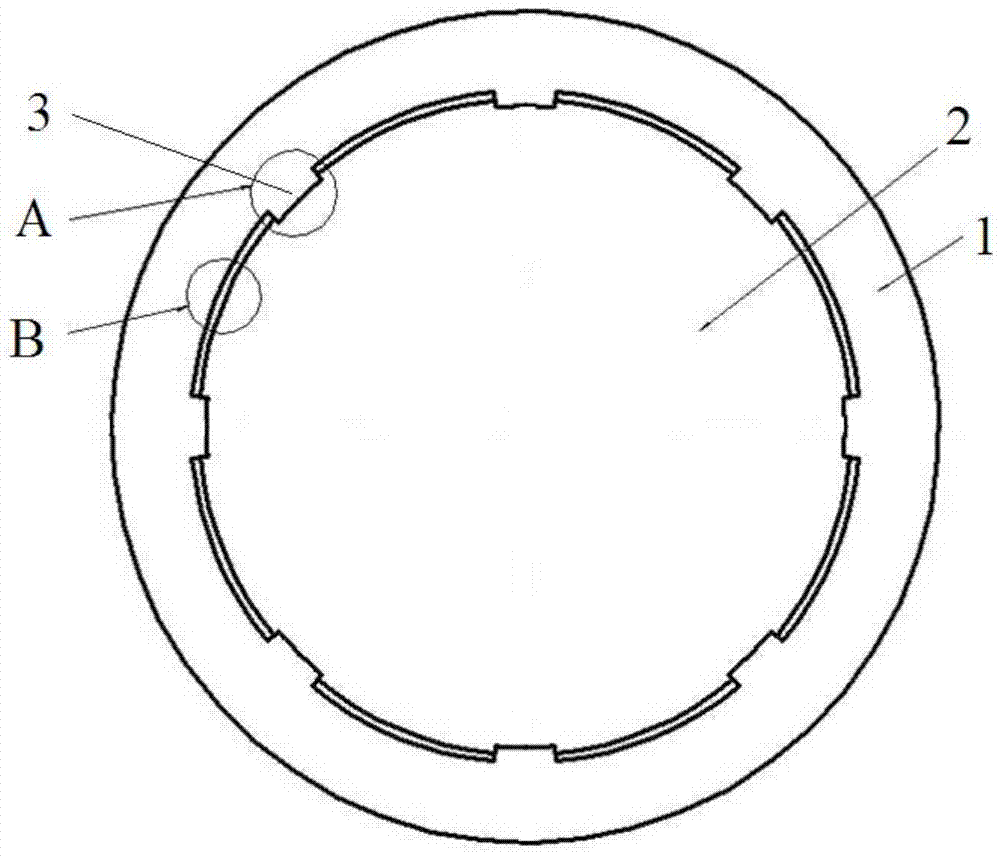

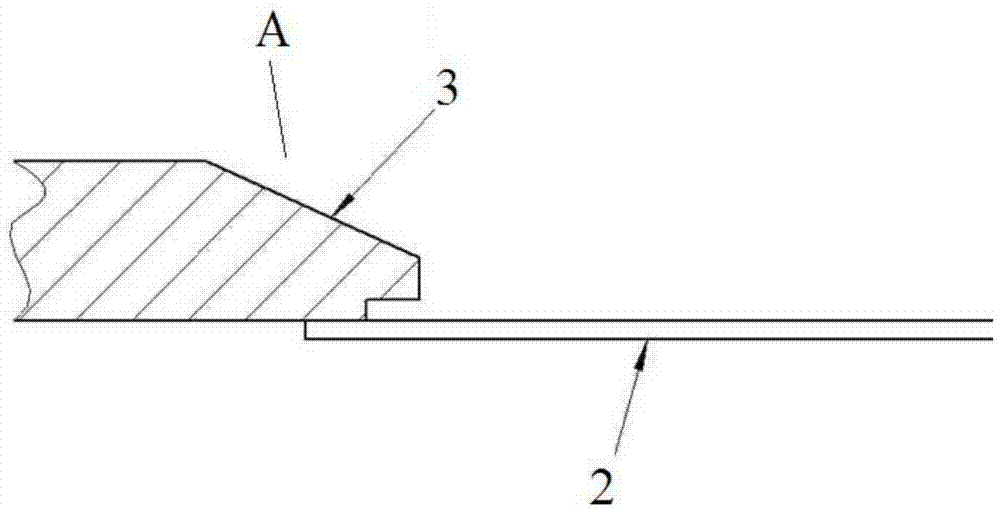

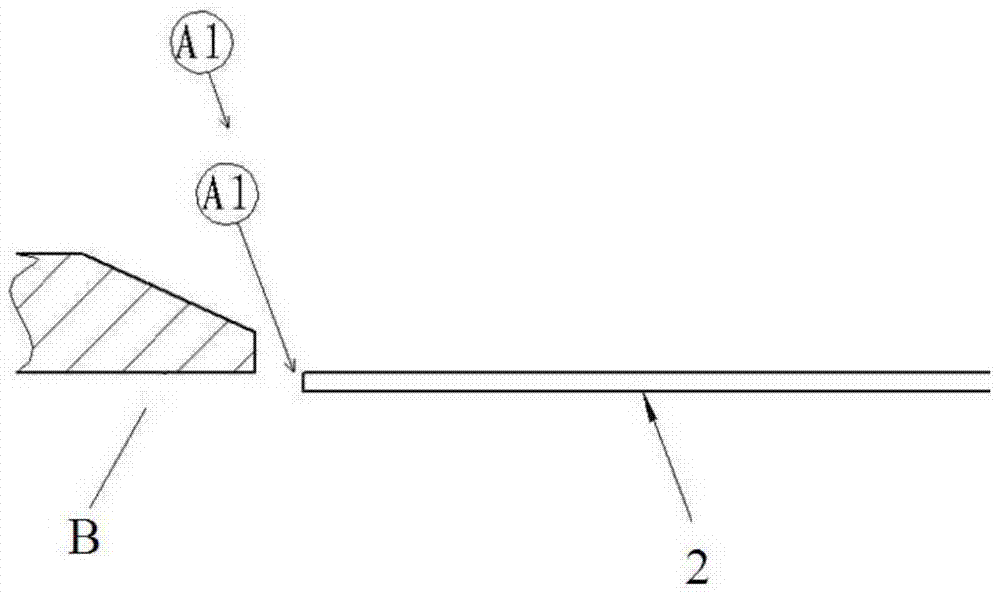

[0031] image 3 A bottom view of a pressure ring provided by an embodiment of the present invention. see image 3 , the press ring is used to fix the wafer by pressing against the edge region of the upper surface of the wafer. The pressure ring includes an outer ring part 11 and an inner ring part 12 which are nested and connected together. That is to say, the pressure ring adopts an integral ring structure and is composed of an outer ring part and an inner ring part. The outer ring The part is the outer ring part 11, the inner diameter D1 of the outer ring part 11 is larger than the diameter of the wafer, so that when the pressure ring presses the wafer, the outer ring part 11 is not in co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com