A chemically cross-linked lead-acid battery mixed colloidal electrolyte

A colloidal electrolyte, lead-acid battery technology, applied in lead-acid batteries, electrolyte immobilization/gelation and other directions, can solve the problems of unstable performance of organic glue, poor performance of inorganic glue, not much improvement in performance, etc. Achieve the effects of fast charge and high current discharge performance, low production cost, and a wide range of battery temperature applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] Example: A chemically cross-linked lead-acid battery mixed colloidal electrolyte, the specific process formula is: prepare 1050KG of mixed gel, including 300KG of organic glue, 600KG of inorganic glue, 50KG of succinic acid, and 100KG of adipic acid.

[0036] 1. Configure inorganic glue and organic glue first:

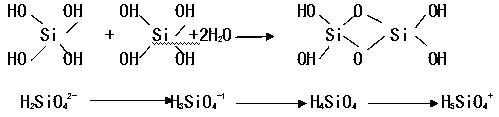

[0037] Inorganic glue including 10-20% SiO 2 , 70-85% water, 0.01%-0.1% stabilizer and 5-10% caustic soda, first cut SiO at a high speed with a high-speed shearing machine with a linear speed of about 4000 rpm 2 15min, forming gas phase SiO 2 ; Then mix the stabilizer and water uniformly at 1:200-1:1000, caustic soda and water at the ratio of 1:4-1:6 and add gas phase SiO 2 Among them, it is configured as inorganic glue.

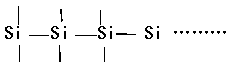

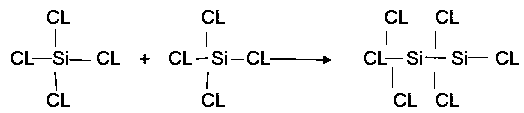

[0038] Organic glue is made of SiCl 4 It is a high-molecular polymer in which the monomer undergoes high-temperature polymerization reaction at a high temperature of more than 1200°C, and when it reaches a molecular weight of 400-800, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com