Preparation method of pure oatmeal

A technology of oatmeal and oatmeal, which is applied to the functions of food ingredients, food ingredients as taste improvers, and food drying. Elevated blood sugar, beneficial effect on growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

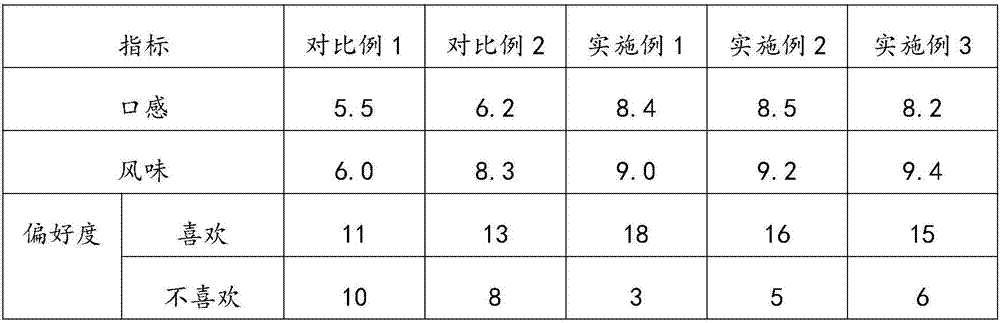

Examples

Embodiment 1

[0035] The preparation method of the pure oatmeal of the present embodiment, comprises the steps:

[0036] (1) Raw material pretreatment: After removing impurities, the oats are dried in a continuous gradient until the water content is 8-10%, so as to obtain oat grains. Wherein, the oats are full-bodied raw oat grains after cleaning, husking and impurity removal, including naked oats and hulled oats; the temperature of continuous gradient drying is 90°C-120°C-60°C respectively.

[0037] (2) Pulverization: the oat granules obtained in step (1) are pulverized into a particle size of 60 mesh to obtain oat flour.

[0038] (3) Enzyme preparation dissolution: Add 100 kg of warm water at 55° C. to a constant temperature enzymatic hydrolysis tank, add 0.25 kg of α-amylase and 0.1 kg of glucoamylase, stir and dissolve to obtain an enzyme preparation solution. Wherein, the α-amylase is produced by Danisco (China) Co., Ltd., and the model is LT, the glucoamylase is produced by Danisco...

Embodiment 2

[0043] The preparation method of the pure oatmeal of the present embodiment, comprises the steps:

[0044] (1) Raw material pretreatment: After removing impurities, the oats are dried in a continuous gradient until the water content is 8-10%, so as to obtain oat grains. Wherein, the oats are full-bodied raw oat grains after cleaning, husking and impurity removal, including naked oats and hulled oats; the temperature of continuous gradient drying is 90°C-120°C-60°C respectively.

[0045] (2) Pulverization: the oat granules obtained in step (1) are pulverized into a particle size of 90 mesh to obtain oat flour.

[0046] (3) Enzyme preparation dissolution: Add 100 kg of warm water at 55° C. to a constant temperature enzymatic hydrolysis tank, add 0.35 kg of α-amylase and 0.15 kg of glucoamylase, stir and dissolve to obtain an enzyme preparation solution. Wherein, the α-amylase is produced by Danisco (China) Co., Ltd., and the model is LT, the glucoamylase is produced by Danisc...

Embodiment 3

[0051] The preparation method of the pure oatmeal of the present embodiment, comprises the steps:

[0052] (1) Raw material pretreatment: After removing impurities, the oats are dried in a continuous gradient until the water content is 8%-10%, and oat grains are obtained. Wherein, the oats are full-bodied raw oat grains after cleaning, husking and impurity removal, including naked oats and hulled oats; the temperature of continuous gradient drying is 90°C-120°C-60°C respectively.

[0053] (2) Pulverization: the oat granules obtained in step (1) are pulverized into a particle size of 120 mesh to obtain oat flour.

[0054] (3) Enzyme preparation dissolution: Add 100 kg of warm water at 55° C. to a constant temperature enzymatic hydrolysis tank, add 0.5 kg of α-amylase and 0.2 kg of glucoamylase, stir and dissolve to obtain an enzyme preparation solution. Wherein, the α-amylase is produced by Danisco (China) Co., Ltd., and the model is LT, the glucoamylase is produced by Danis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com