Transport device, a production installation, a multistage forming press, and a method for manufacturing products from work pieces by means of a production installation

A technology for conveying devices and production devices, which is applied in the direction of conveyor objects, conveyors, mechanical conveyors, etc., can solve the problems of not being fully utilized by tools, and achieve the effects of weight saving, flexible transportation, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

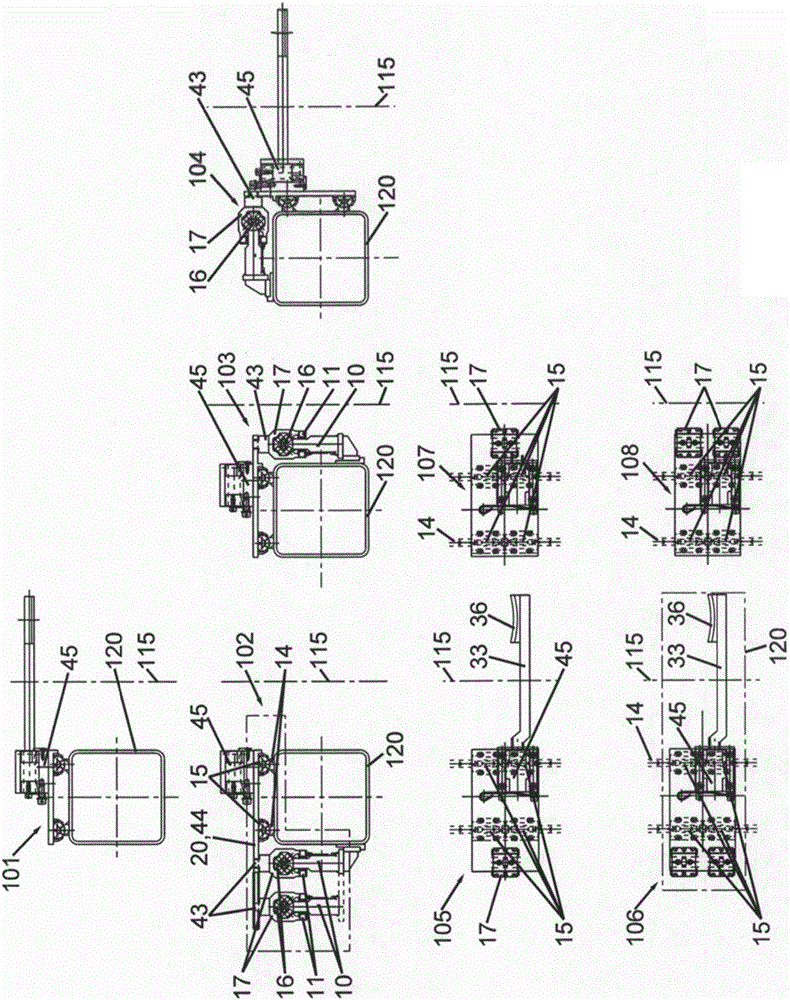

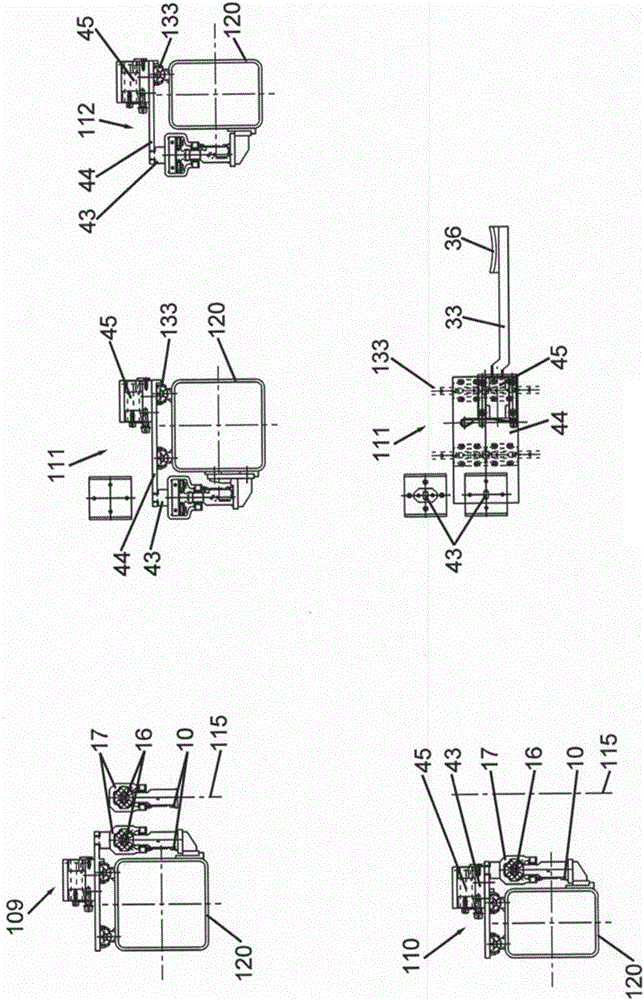

[0092] The drive-free transport gripper 101 is arranged on a transport rail 120 and has a cassette holder 45 .

[0093] In an alternative, the conveying gripper 102 is arranged on a conveying rail 120 and has two external drives 10 , 11 , 16 and 17 arranged in parallel. The drives 10 , 11 , 16 and 17 are arranged on a conveyor rail 120 . The driving devices 10 , 11 , 16 and 17 are connected to the cartridge holder 45 via the driver 43 and the connecting plate 44 . Guides 14 and 15 are arranged on the conveyor rail 120 as stiffening elements when loaded by workpieces.

[0094] In one alternative, the transport gripper 103 has internally arranged drives 10 , 11 , 16 and 17 , which are located on the side of the machine center line 115 .

[0095] In an alternative, the transport gripper 104 has a drive arranged above.

[0096] In an alternative, the transport gripper 105 has an externally arranged drive 17 (in plan view). Furthermore, the transport gripper 105 has a cassette ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com