High-efficiency small and deep hole production machine tool

A high-efficiency, machine tool technology, applied in the direction of milling machines, milling machine equipment, metal processing machinery parts, etc., can solve problems such as wasting time and reducing work efficiency, achieve faster processing speed, improve work efficiency, and save time for changing milling cutters Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

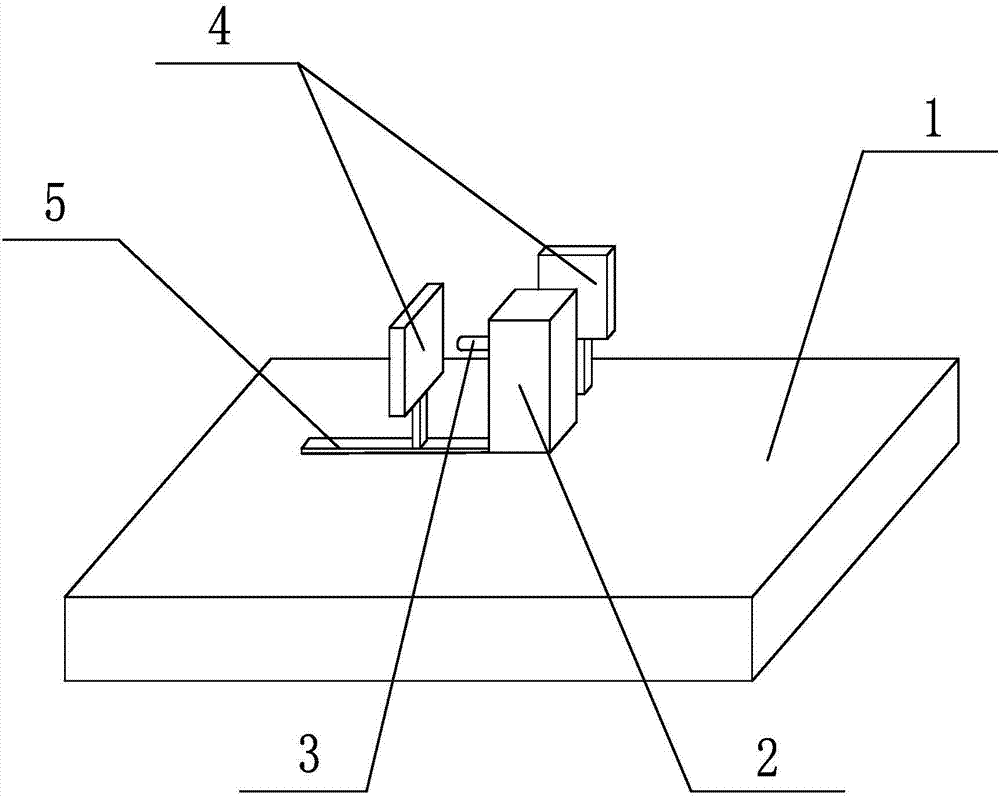

[0021] like figure 1 As shown, the high-efficiency small deep hole production machine tool of the present invention comprises a machine tool 1. A transmission mechanism 2 is provided on the machine tool 1. The transmission mechanism 2 is connected with 4 horizontally arranged drilling milling cutters 3, and two adjacent drilling holes The included angle between the milling cutters 3 is 90°, the transmission mechanism 2 is flexibly connected with the machine tool, and the transmission mechanism 2 can rotate around its own axis; four feeding mechanisms 4 are arranged around the transmission mechanism 2, each Each feeding mechanism 4 corresponds to a drilling milling cutter 3 one by one, and the feeding mechanism 4 is connected with the machine tool 1 through a slide rail 5 .

[0022] The deep hole production machine tool of the present invention can perform deep hole processing on multiple workpieces at the same time, and at the same time, when it is necessary to process deep ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com