Water power ship

A hydrodynamic and power engine technology, applied in ship propulsion, ship parts, ship construction, etc., can solve problems such as entanglement of foreign debris, difficulty in removing debris, and increase in navigation difficulty, so as to increase the thrust of the ship and avoid the sinking of the hull , The effect of reducing the difficulty of sailing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

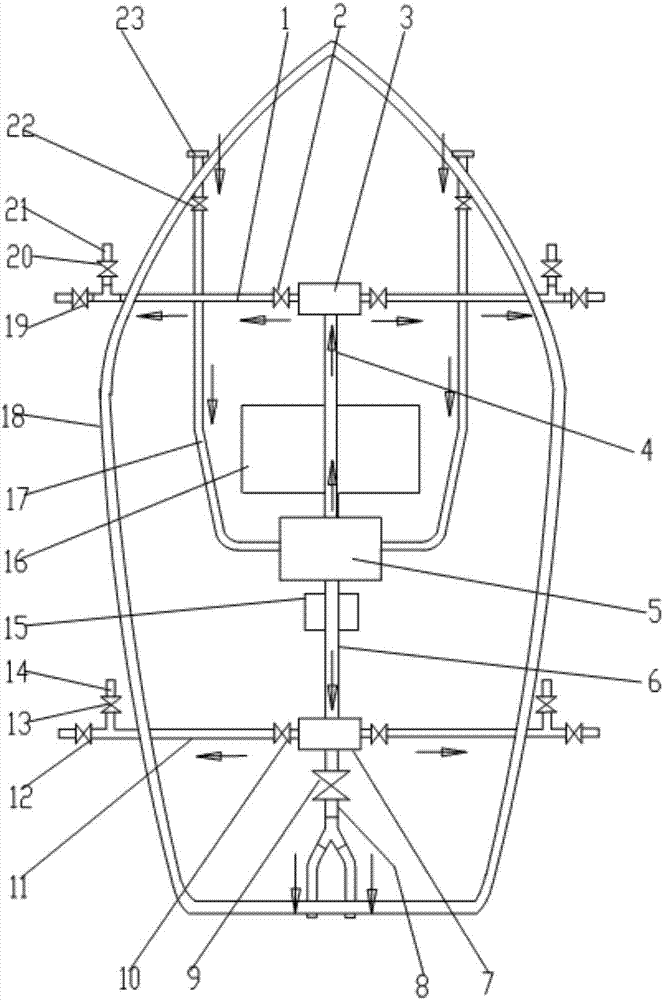

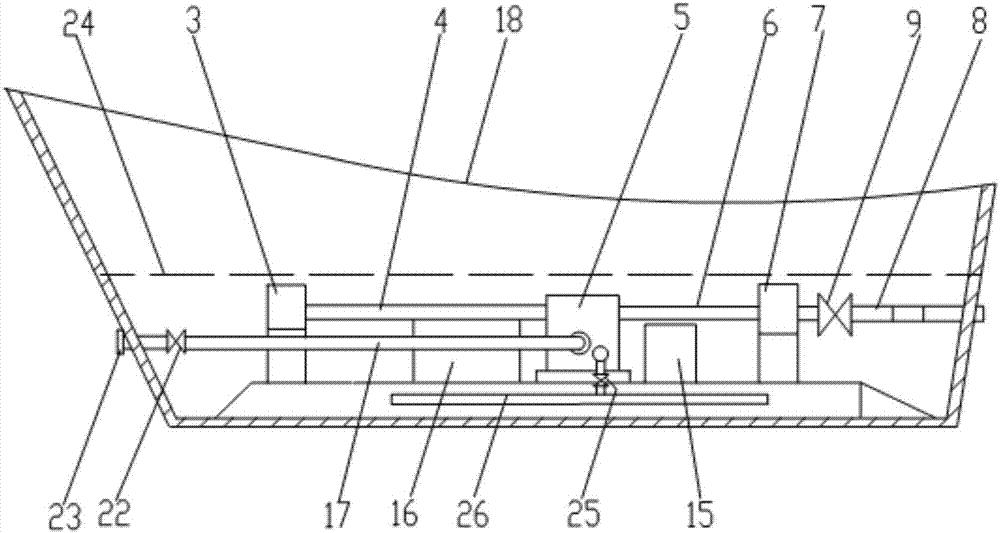

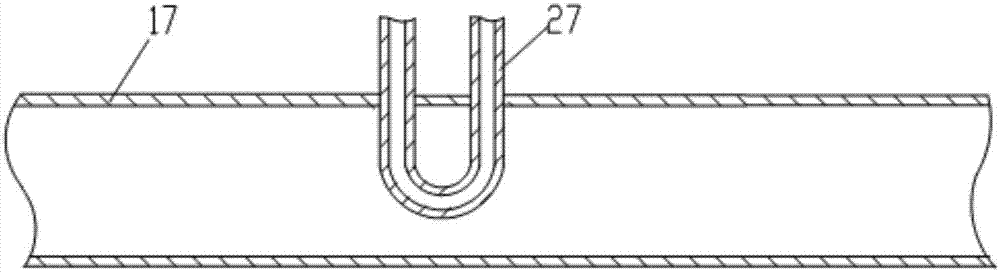

[0024] see figure 1 , 2 ;

[0025] 1. Open the first electric valve 22 and the second electric valve 9, close all other valves, pressurize through the water pump inlet pipe 17 and the water pump 5, and the high-pressure water passes through the water outlet pipe 6 after the water pump, the second electric valve 9 and the water spray at the stern in sequence Pipe 8 drains and produces reaction force, drives hydrodynamic ship to advance.

[0026] 2. Open the first electric valve 22, the third electric valve 2 and the fifth electric valve 20, all other valves are closed, pressurize through the water pump inlet pipe 17 and the water pump 5, and the high-pressure water passes through the front outlet pipe 4 of the water pump and the third electric valve in turn. Valve 2 and the fifth electric valve 20 produce anti-thrust towards the forward drainage, so that the hull 18 stops moving forward or retreating. Also can revise backward direction by water spray pipe 11 of rear ship's s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com