Environment-friendly quick-drying high-solid-content alkyd resin and preparation method thereof

An alkyd resin, high solid content technology, applied in the field of coatings and industrial paints, can solve the problems of high resin viscosity and slow drying, and achieve the effect of reducing the volatilization of organic substances, more film-forming substances, and reducing environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

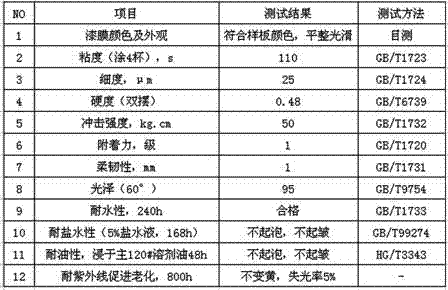

Examples

Embodiment 1

[0018] Alkyd resin is composed of the following raw materials according to mass percentage: 16% soybean oil, 16% dimer acid, 20% phthalic anhydride, 5% pentaerythritol, 9% diethylene glycol, 10% isophthalic acid, Reflux xylene 2%, environment-friendly solvent propylene glycol methyl ether 22%.

[0019] The soyoleic acid was purchased from Qiqihar Huayi Oil Co., Ltd., the dimer acid was purchased from Jiangsu Yonglin Oil Chemical Co., Ltd., the phthalic anhydride was purchased from Harbin No. 5 Chemical Factory, and the pentaerythritol was purchased from Jinan Yinhe Chemical Co., Ltd. Company, isophthalic acid was purchased from Hubei Xinyinhe Chemical Co., Ltd., propylene glycol methyl ether was purchased from Jiangsu Hualun Chemical Co., Ltd., diethylene glycol was purchased from Runcang (Qingdao / Yantai) Chemical Co., Ltd., and reflux two Toluene was purchased from Jilin Chemical Industry Co., Ltd.

[0020] The preparation method is as follows.

[0021] Step 1. First, slowl...

Embodiment 2

[0033] Alkyd resin is composed of the following raw materials according to mass percentage: 15% soy oil, 15% dimer acid, 25% phthalic anhydride, 7% pentaerythritol, 8% diethylene glycol, 15% isophthalic acid, Reflux xylene 3%, environment-friendly solvent propylene glycol methyl ether 12%.

Embodiment 3

[0035] The alkyd resin is composed of the following raw materials according to the mass percentage: 14% soybean oil, 14% dimer acid, 20% phthalic anhydride, 6% pentaerythritol, 7% diethylene glycol, 11% isophthalic acid, Reflux xylene 5%, environment-friendly solvent propylene glycol methyl ether 23%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com