Measuring-compensating device and method for single-frequency interference linearity error and position thereof

A straightness error, single-frequency technology, applied to measuring devices, optical devices, instruments, etc., can solve problems such as limited measurement accuracy, low measurement accuracy, limiting straightness and position measurement accuracy, and avoid calculation errors , Improve the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with drawings and embodiments.

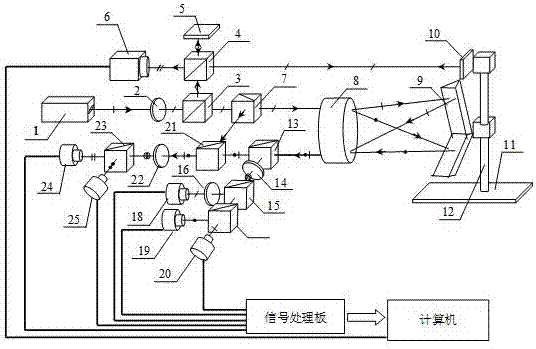

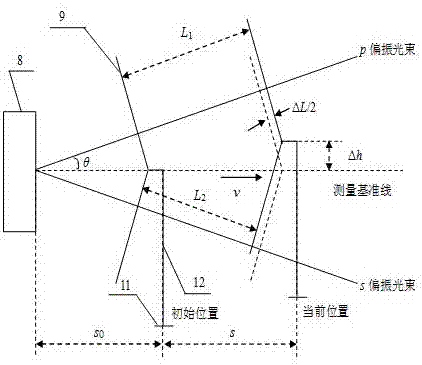

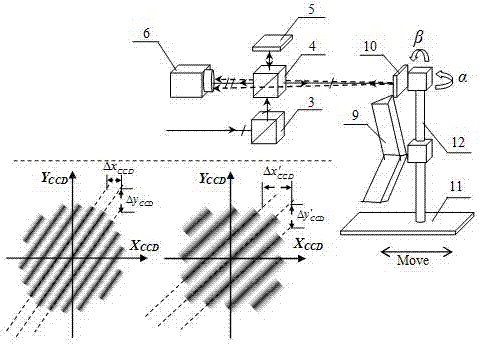

[0035] Such as figure 1 As shown, the present invention selects a single-frequency laser 1 capable of outputting linearly polarized light. After the linearly polarized light beam output by it passes through the half-wave plate 2, the polarization direction is adjusted to be 45° relative to the paper surface;

[0036] The modulated linearly polarized beam is split by the first depolarizing beam splitter 3, and the transmitted beam enters the third depolarizing beam splitting prism 7, the Wollaston prism 8, the measuring mirror 9 composed of upper and lower rectangular prisms, and the fourth depolarizing beam Dichroic prism 13, the first quarter-wave plate 14, the fifth depolarizing beam-splitting prism 15, polarizer 16, the first polarizing beam-splitting prism 17, the second polarizing beam-splitting prism 21, the second quarter-wave plate 22 and The Wollaston prism ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com