Universal rotation speed source for aircraft engine

A technology for engines and aircraft, applied in the field of general speed source, can solve problems such as poor versatility and comprehensiveness, impact on support efficiency, poor scalability, etc., achieve obvious military benefits, high speed adjustment accuracy, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to illustrations. While illustrations of parameters including particular values may be provided herein, it should be understood that parameters need not be exactly equal to the corresponding values, but rather may approximate the values within acceptable error margins or design constraints.

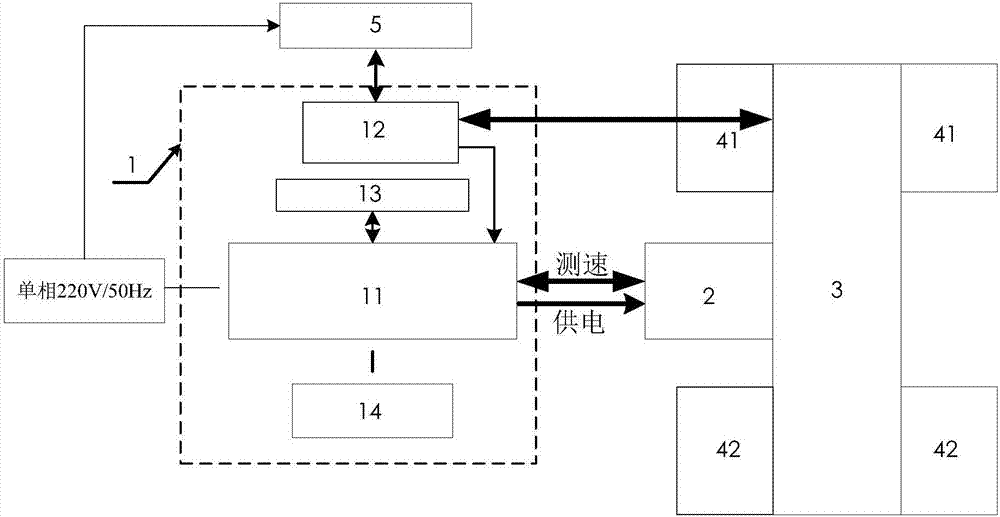

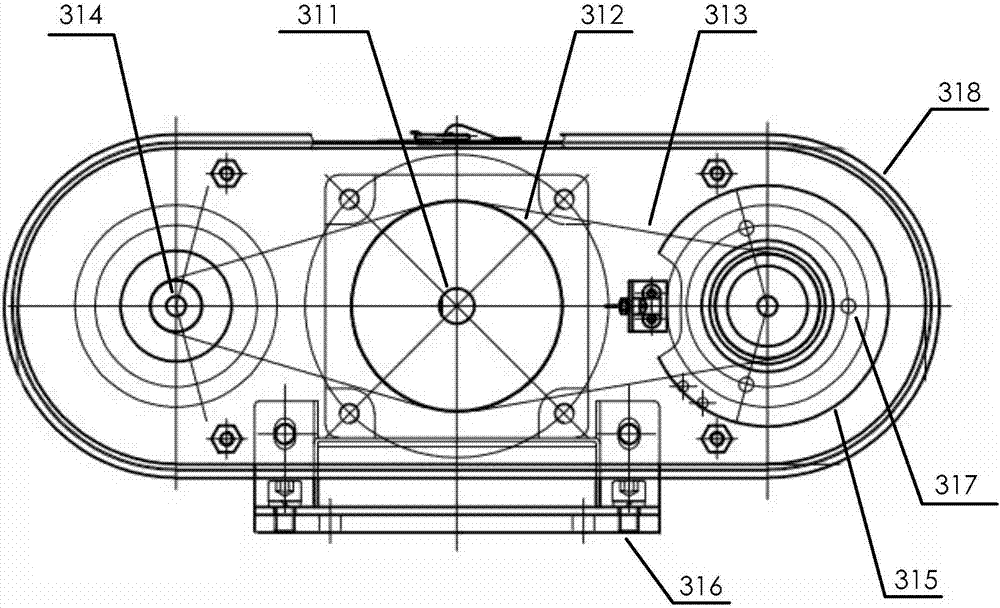

[0023] figure 1 It is a schematic structural diagram of a universal rotational speed source suitable for aircraft engines according to an embodiment of the present invention. Such as figure 1 As shown, it consists of a speed controller (1), a brushless DC motor (2), a speed increasing device (3), a transition connection device (4) and a speed display device (5).

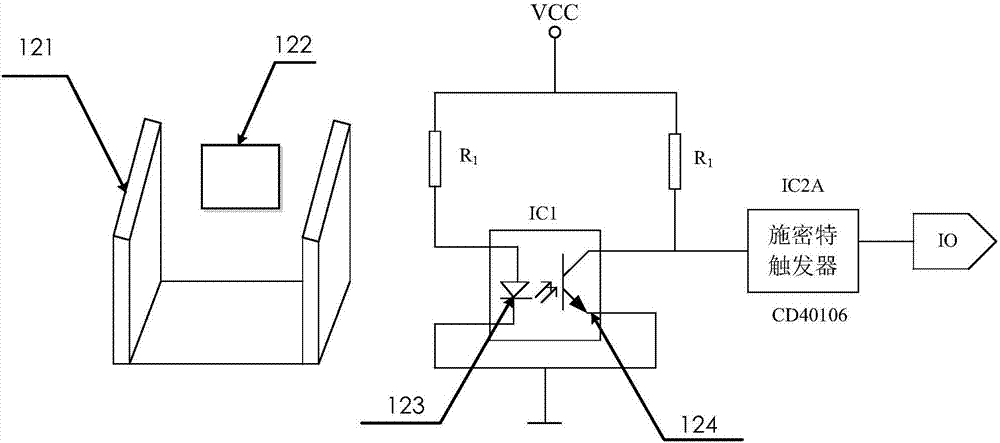

[0024] The speed controller (1) includes a motor control driver (11), a speed measuring mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com