A high-resolution detection and identification method for debonding defects in composite materials

A composite material and high-resolution technology, applied in character and pattern recognition, instruments, computing, etc., can solve problems such as low resolution, blurred edges, noise interference, etc., and achieve the effect of improving resolution, improving contrast, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

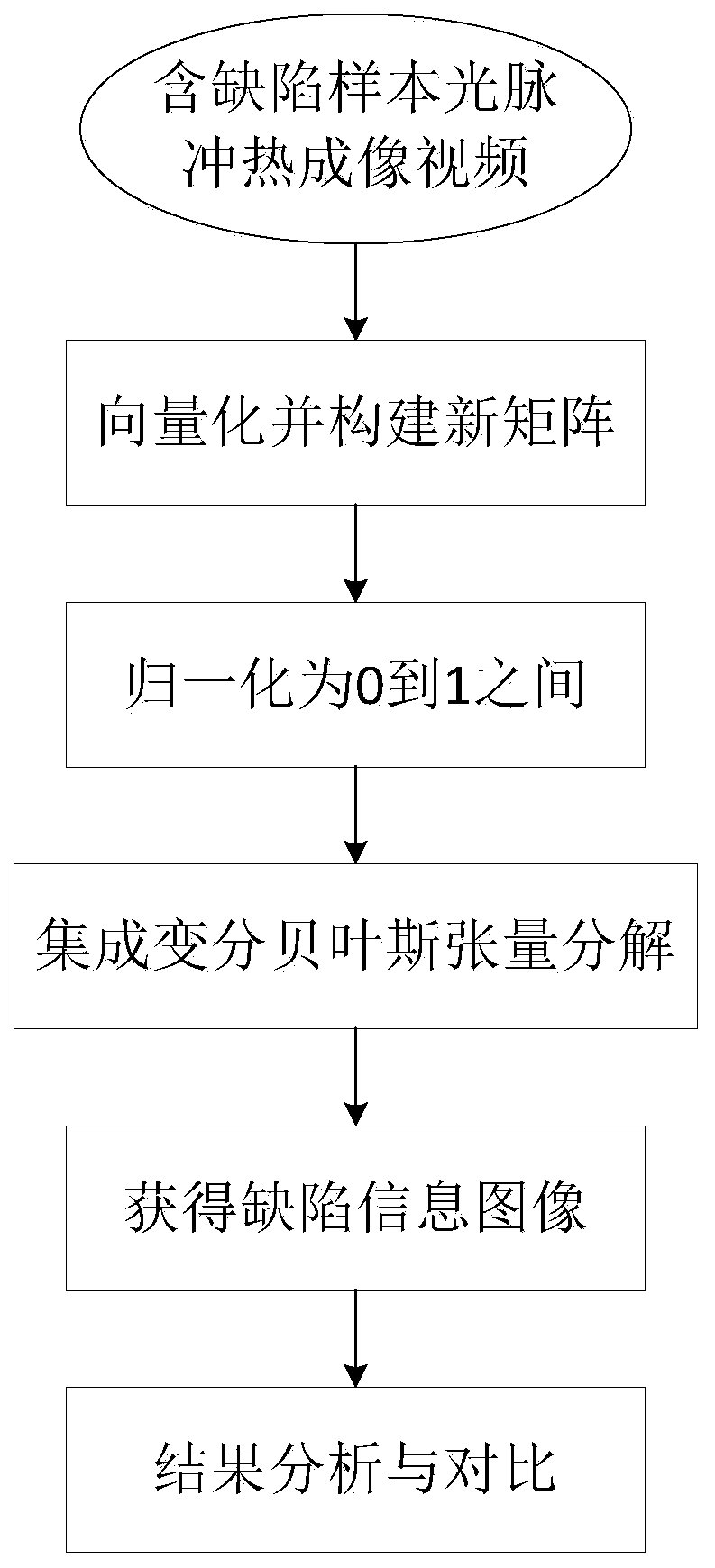

[0023] figure 1 It is a flowchart of a high-resolution detection and identification method for debonding defects of composite materials in the present invention.

[0024] In this example, if figure 1 As shown, a kind of high-resolution detection and identification method to composite material debonding defect of the present invention comprises the following steps:

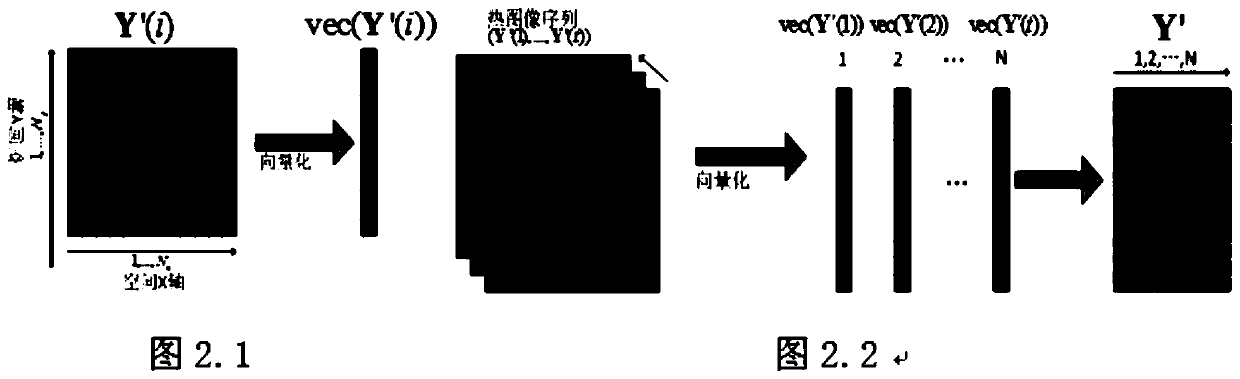

[0025] S1, preprocessing

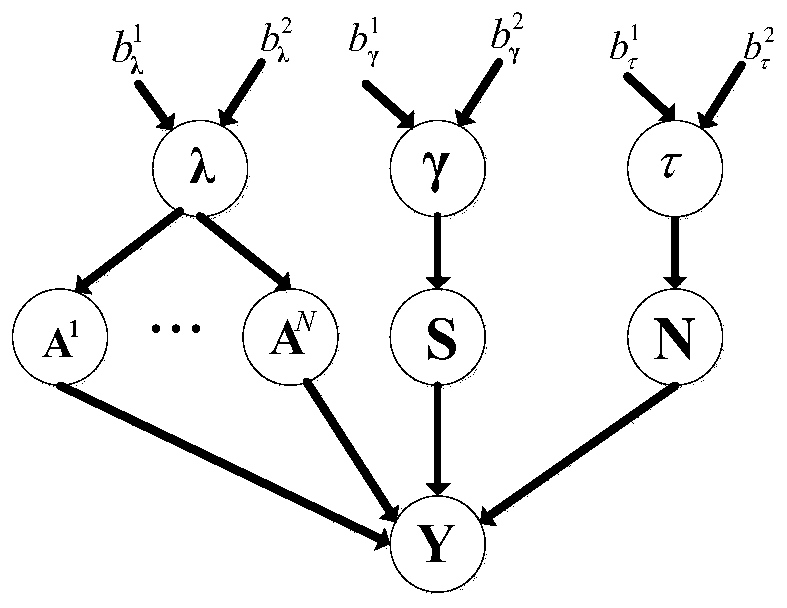

[0026] When the test piece is excited by the heat source, in the process of thermal equilibrium, part of the defect information can be displayed in the infrared thermal image, and the physical characteristics of the surface temperature field changing with time and space can be expressed by known mathematical models. When performing theoretical analysis, the temperature change of each pixel point can be simplified into a one-dimensional heat conduction model, and post-processing analysis is performed on this basis. The mathematical model of the surface temperature of the specimen can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com