MnTe2/Ni electrode material for super-capacitor and preparation method thereof

A technology for supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc. It can solve the problems of environmental pollution restrictions, low energy density, poor conductivity, etc., and achieve simple preparation process and low investment in equipment capital , time-consuming effect

Inactive Publication Date: 2017-06-23

ZHEJIANG UNIV

View PDF3 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Among transition metal oxides, RuO 2 It has a high specific capacitance, but its high cost, low reserves and serious environmental pollution limit its practical application

Other transition metal oxides such as MnO 2 , NiO and Co 3 o 4 , has also been extensively studied, th

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Charge transfer resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

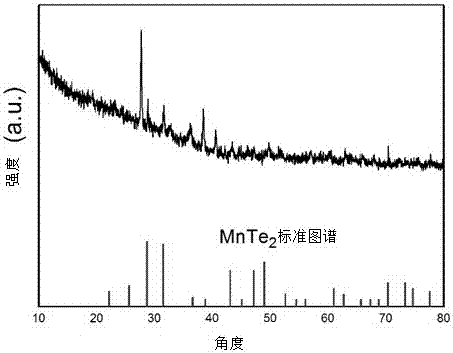

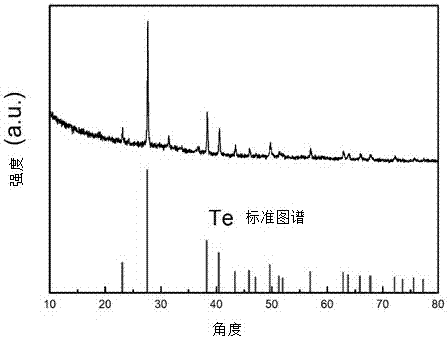

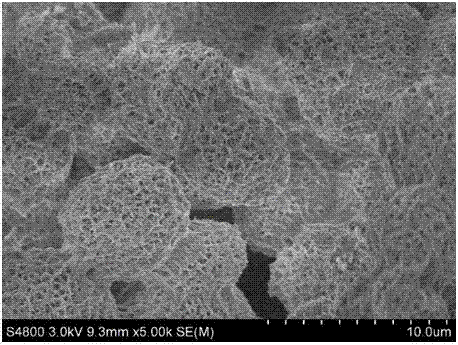

The invention discloses a MnTe2/Ni electrode material for a super-capacitor. MnTe2 is adopted as an electrode active material to be covered on a Ni substrate. The MnTe2 is formed to be of a hemisphere-shaped honeycomb structure. The MnTe2 hemisphere-shaped honeycomb structure is encircled by MnTe2 sheets to form a large number of cellular pores. The invention also discloses a preparation method of the MnTe2/Ni electrode material. The method comprises the steps of weighing a tellurium source, a manganese source and a reducing agent; putting the above materials into a reaction kettle, and adding a solvent; fully stirring and placing a foam nickel sheet in the reaction kettle; subjecting the above materials to reaction in a heating furnace; taking out an obtained product, repeatedly washing the product with anhydrous ethanol and deionized water, and then drying the product to obtain the MnTe2/Ni electrode material. The specific capacitance of the prepared MnTe2/Ni electrode material at the discharge current of 10 mA is 116.9F*g/1. After 5000 times of cycles, the capacitance of the material can still be maintained to be 100%. Therefore, the good cycling stability is realized.

Description

technical field [0001] The invention relates to the field of batteries, in particular to the field of electrode materials for supercapacitors and a preparation method thereof. Background technique [0002] Supercapacitor is a new type of energy storage device, which uses porous carbon materials with high specific surface area as electrodes or uses electrode active materials for underpotential deposition, so that it can undergo rapid and reversible chemical adsorption / desorption or oxidation / reduction reactions to Obtain the capacitance of the order of Faraday, so it has both the energy storage characteristics of the battery and the power characteristics of the capacitor. It is thousands of times higher than the specific energy of the traditional electrolytic capacitor, and the leakage current is thousands of times smaller. It can charge and discharge 100,000 times More than one time without maintenance and maintenance, it can be used in the working state of instantaneous dis...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01G11/24H01G11/30H01G11/86

CPCY02E60/13H01G11/24H01G11/30H01G11/86

Inventor 吕建国汤海潮李佳宁

Owner ZHEJIANG UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com