Minkowski-based microstrip patch antenna and manufacturing method thereof

A microstrip patch antenna and microstrip patch technology, which are applied in the field of wireless communication, can solve the problems of antenna size limitation, large antenna size, and difficulty in conformality, and achieve the effect of overcoming large size, easy integration, and easy conformality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with drawings and embodiments.

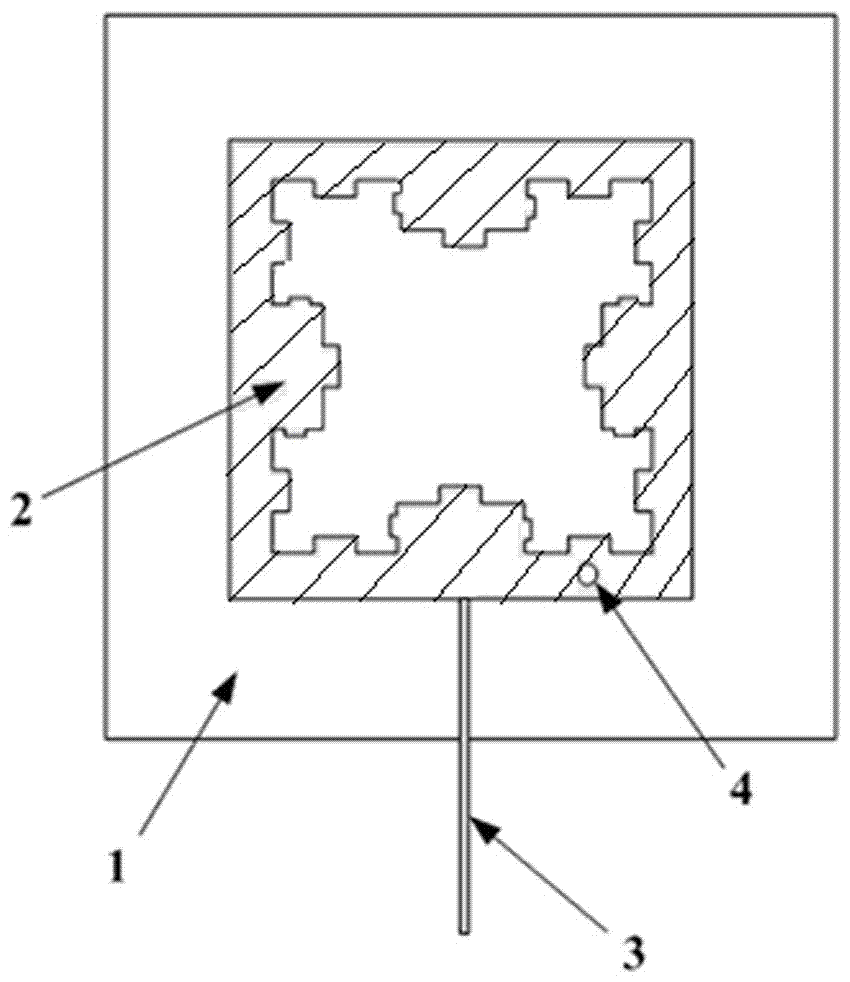

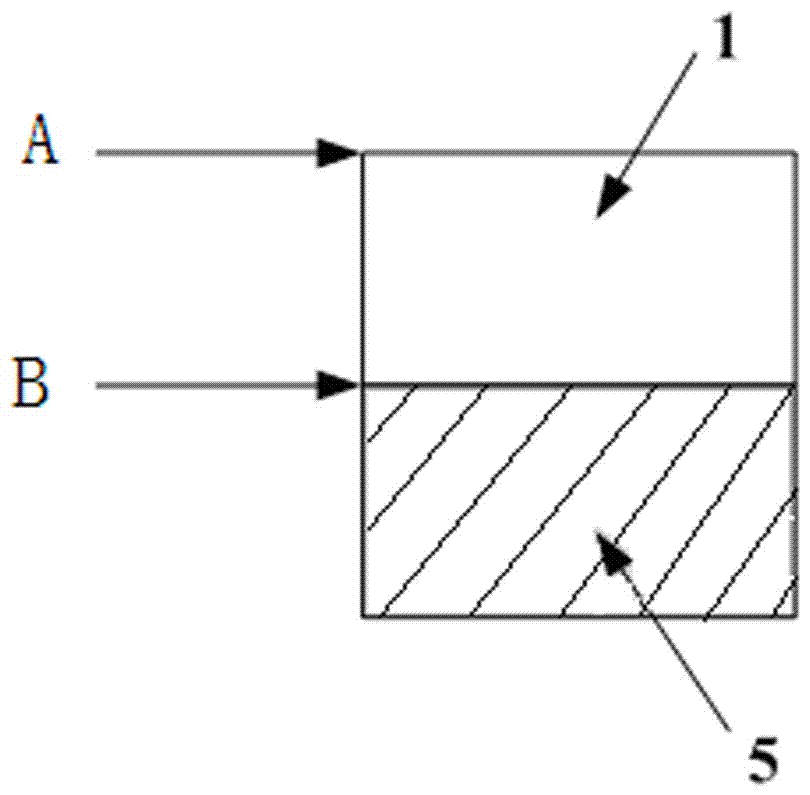

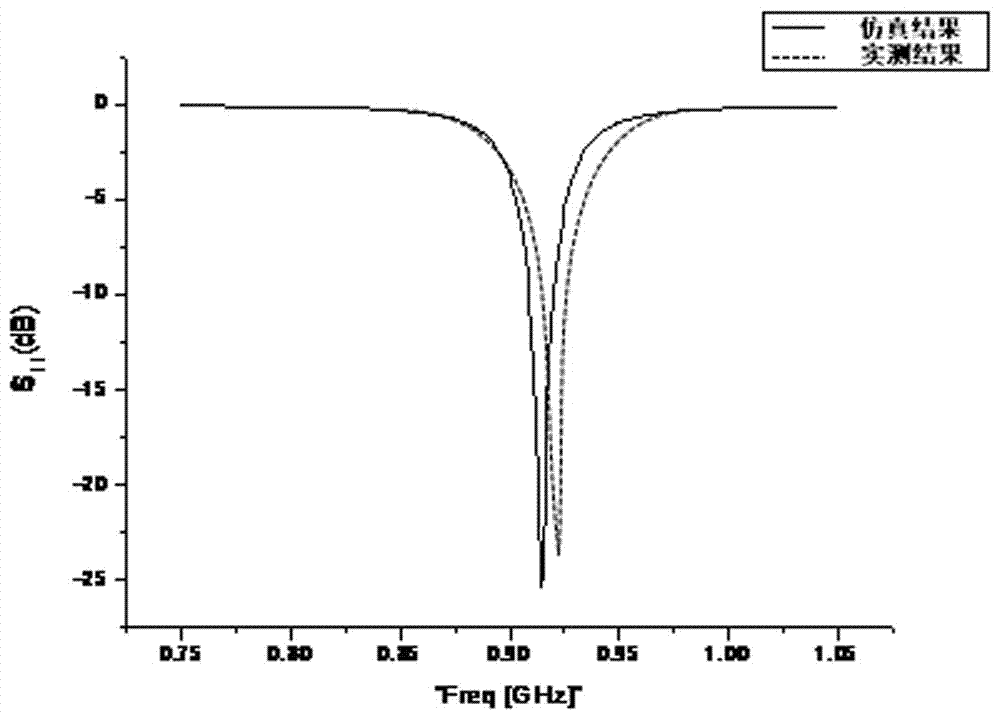

[0029] like figure 1 , 2 As shown, a microstrip patch based on the secondary Minkowski fractal structure is composed of a dielectric plate 1, a radiation unit 2, a feed unit 3, a ground via 4 and a ground unit 5, and the dielectric plate has a first surface A and the second surface B corresponding thereto; the radiation unit 2 is arranged on the first surface A of the dielectric board 1; the feed unit 3 is connected to the radiation unit 2 and is also arranged on the first surface A of the dielectric board 1 Above; the ground via hole 4 passes through the radiation unit 2 and the dielectric board 1 when punching, so that the radiation unit 2 communicates with the ground unit 5 to form a short circuit; the ground unit 5 is arranged on the second surface B of the dielectric board 1, and The dielectric plate 1 may not be completely covered. However, the high-frequency e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Return loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com