Preparation method for alkali-chelated palygorskite-based heavy metal passivation material

A heavy metal, palygorskite technology, applied in chemical instruments and methods, soil conditioning materials, organic fertilizers and other directions, can solve the problems of increasing, limited use of palygorskite, increasing the amount of palygorskite, etc., to facilitate crushing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A preparation method of an alkali-chelated palygorskite-based heavy metal passivation material, comprising the steps of:

[0027] A. to dry naturally

[0028] The palygorskite ore is dried in the sun for 3-7 days to prevent rainwater from soaking the palygorskite;

[0029] B. Crushed and sieved

[0030] The palygorskite ore is crushed into palygorskite clay, and the palygorskite clay is sieved with a filter mesh of 150-200 mesh;

[0031] C. Alkaline chelation

[0032] Mix the palygorskite clay with the quicklime solution and stir to make it evenly mixed;

[0033] D. Precipitation, drying and crushing

[0034] The mixed solution is allowed to stand for precipitation, and the precipitate is dried and crushed to obtain the finished product.

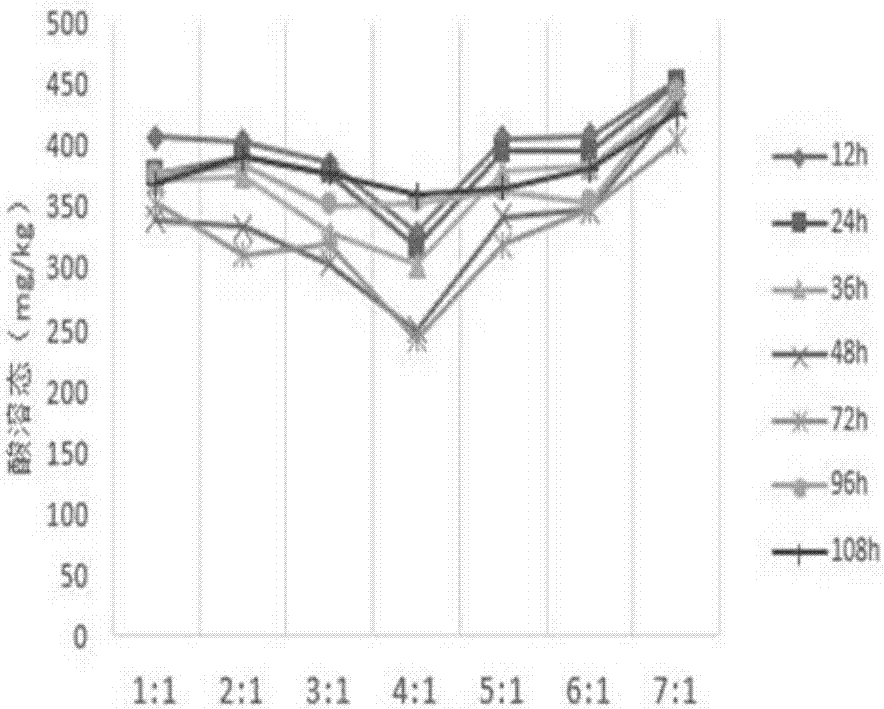

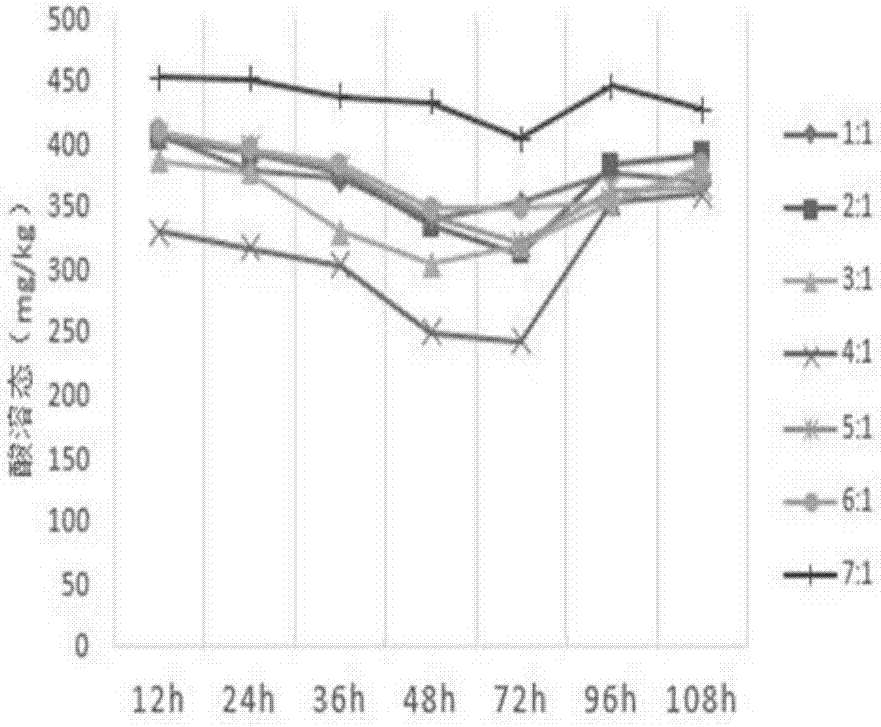

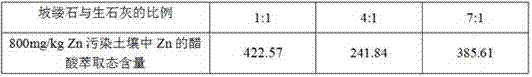

[0035] In the preferred step C, palygorskite clay and quicklime are mixed in a weight ratio of 1:1 to 7:1, quicklime is mixed with water to prepare a quicklime solution, and palygorskite clay is added to the quicklime solution, a...

Embodiment 1

[0041] A preparation method of an alkali-chelated palygorskite-based heavy metal passivation material, comprising the steps of:

[0042] A. to dry naturally

[0043] The palygorskite ore is dried in the sun for 3-7 days to prevent rainwater from soaking the palygorskite;

[0044] B. Crushed and sieved

[0045] The palygorskite ore is crushed into palygorskite clay, and the palygorskite clay is sieved with a filter mesh of 150-200 mesh;

[0046] C. Alkaline chelation

[0047] Palygorskite clay and quicklime are mixed in a weight ratio of 1:1~7:1, quicklime and water are mixed to prepare a quicklime solution, and palygorskite clay is added to the quicklime solution, and stirred at a stirring speed of 500 r / min for 12~108h, make it evenly mixed;

[0048] D. Precipitation, drying and crushing

[0049] The mixed solution is allowed to stand for precipitation, and the precipitate is dried and crushed to obtain the finished product.

Embodiment 2

[0051] A preparation method of an alkali-chelated palygorskite-based heavy metal passivation material, comprising the steps of:

[0052] A. to dry naturally

[0053] The palygorskite ore is dried in the sun for 3-7 days to prevent rainwater from soaking the palygorskite;

[0054] B. Crushed and sieved

[0055] The palygorskite ore is crushed into palygorskite clay, and the palygorskite clay is sieved with a filter mesh of 150-200 mesh;

[0056] C. Alkaline chelation

[0057] Palygorskite clay and quicklime are mixed in a weight ratio of 3:1~4:1, quicklime and water are mixed to prepare a quicklime solution, and palygorskite clay is added to the quicklime solution, and stirred for 72 hours at a stirring speed of 500 r / min to make it Mix evenly Mix the palygorskite clay with the quicklime solution and stir to make it evenly mixed;

[0058] D. Precipitation, drying and crushing

[0059] The mixed solution is allowed to stand for precipitation, and the precipitate is dried and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com