Preparation method of early strength prestress duct grouting material

A pore grouting and prestressing technology, applied in the field of concrete slurry preparation, can solve the problems of insufficient structural strength, potential safety hazards, poor fluidity, etc., and achieve the effects of excellent early strength performance, reduced production cost, and excellent micro-expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

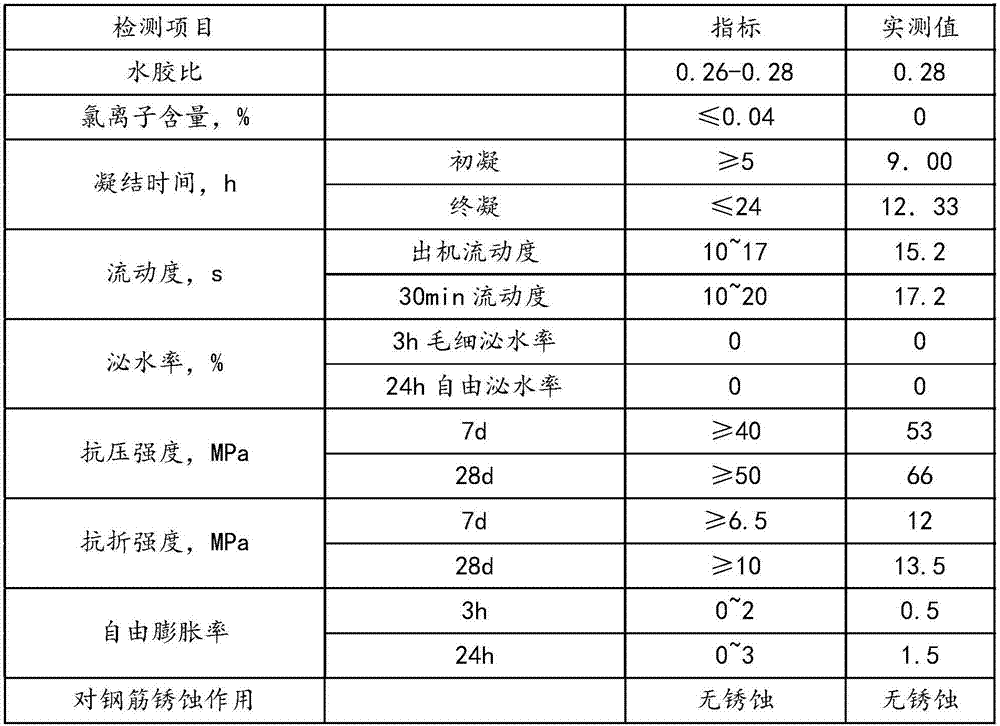

Embodiment 1

[0023] Embodiment 1: Select 725.3 parts of cement, 200 parts of waste glass powder, 50 parts of pozzolan, 1.5 parts of polycarboxylate superplasticizer, 3 parts of Wenlun rubber, 20 parts of UEA micro-expansion agent, 0.2 part of organic silicon defoamer, water The glue ratio is 0.28. Place waste glass powder raw materials and volcanic ash in a wet mill, add 125 parts of water, and ball mill after 3 hours of wet milling until the median particle size is less than 1 micron, then add cement and remaining water to the wet mill for wet milling and stirring, then add micro-expansion After mixing the agent, Wenlun glue, water reducer and defoamer, they can be released and used. The time from adding cement to discharging does not exceed 90s.

[0024]

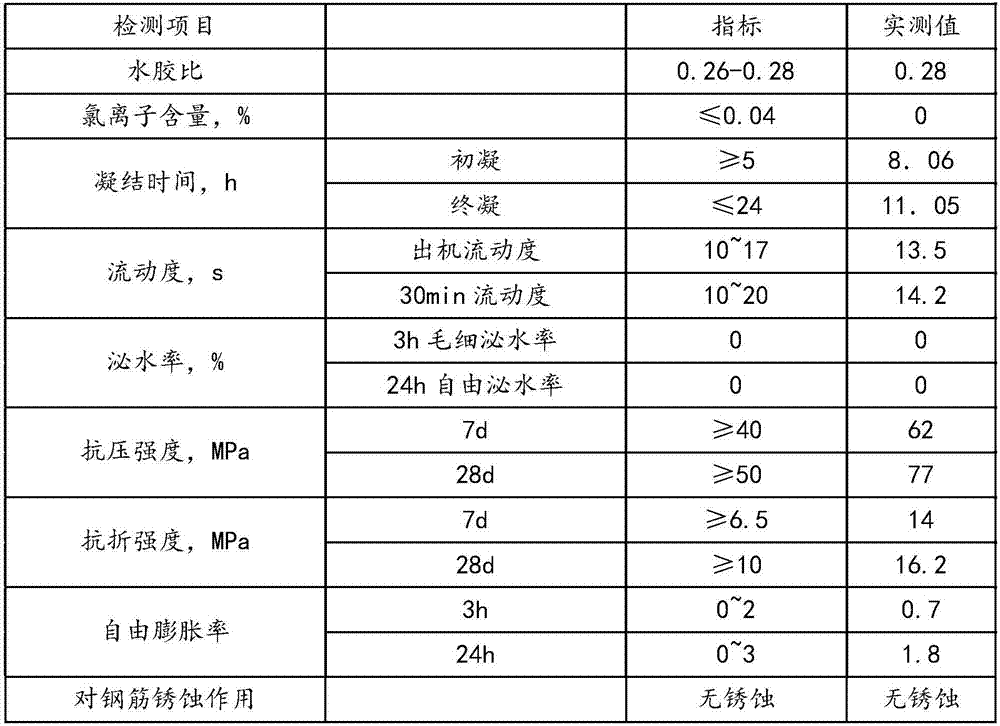

Embodiment 2

[0025] Embodiment 2: Select 532.5 parts of cement, 300 parts of waste glass powder, 100 parts of pozzolan, 2.5 parts of polycarboxylate superplasticizer, 4 parts of Wenlun rubber, 60 parts of UEA micro-expansion agent, 1 part of organic silicon defoamer, water The glue ratio is 0.28. Place waste glass powder raw materials and volcanic ash in a wet mill, add 200 parts of water, and wet mill for 3 hours, then add cement and the remaining water to the wet mill and stir, then add micro-expansion agent, construction-grade warm wheel glue, The water agent and defoamer can be released for use after stirring well, and the time from adding cement to discharging does not exceed 90s.

[0026]

Embodiment 3

[0027] Embodiment three: choose 628.9 parts of cement, 250 parts of waste glass powder, 75 parts of volcanic ash, 2 parts of polycarboxylate superplasticizer, 3.5 parts of Wenlun rubber, 40 parts of UEA micro-expansion agent, 0.6 part of organic silicon defoamer, water The glue ratio is 0.28. Place waste glass powder raw materials and volcanic ash in a wet mill, add 162.5 parts of water, and after wet milling for 3 hours, add cement and the remaining water to the wet mill in sequence, then add micro-expansion agent, construction-grade temperature wheel glue, reducing The water agent and defoamer can be released for use after stirring well, and the time from adding cement to discharging does not exceed 90s.

[0028]

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com