Epoxy resin composition for prepreg, preparation method thereof, and the prepreg

A technology of epoxy resin and solid epoxy resin, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problem of narrow process window, short minimum viscosity retention time and insufficient mechanical properties of prepreg And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

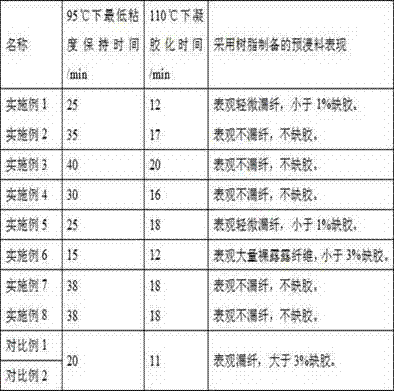

Examples

preparation example Construction

[0028] A preparation method of epoxy resin composition for prepreg, the method comprises mixing solid epoxy resin and toughening agent to obtain component A, curing liquid epoxy resin, dicyandiamide curing agent and imidazole The agent and the urea accelerator are mixed to prepare the B component, and then the B component is mixed with the A component to prepare the epoxy resin composition.

[0029] The specific preparation method of component B: Weigh an appropriate amount of liquid epoxy resin, and pour an appropriate amount of epoxy curing-promoting composite system powder into the liquid epoxy resin, and use mechanical stirring at room temperature to disperse the powder evenly in liquid epoxy resin. The stirring speed is preferably lower than 10rmp / min, and the stirring time is 20min. Then, the three-roll mill is equipped with cooling circulating water, and the stirred system is poured into the three-roll mill for grinding. After grinding once, the required abrasive is p...

Embodiment 1

[0036] The composition and weight percentage of epoxy resin for prepreg described in this example are as follows: solid epoxy resin E12: 35%, toughening agent 860820-S: 25%, liquid epoxy resin E51: 25%, (dicyandiamide Amine curing agent: imidazole curing agent: urea accelerator = 1:2:1.5): 15%. 100 parts by weight of dicyandiamide curing agent, imidazole curing agent and urea accelerator are the basis, wherein the imidazole curing agent is the LC-80d curing agent product of Catalysts company, and the consumption is 44.45 parts, and the particle diameter is 500nm; The cyanamide curing agent is dicyandiamide produced by Jinan Tianyou Chemical Co., Ltd., with a particle size of 20 μm; the urea accelerator is N-p-chlorophenyl N', N'-dimethylurea, selected from the new code N-p-chlorophenyl N',N'-dimethylurea from Chemical Materials (Shanghai) Co., Ltd.

[0037] The production process is as follows: ① solid epoxy resin and toughening agent are melted at 90°C and mechanically stirr...

Embodiment 2

[0039] The composition and weight percent of epoxy resin for prepreg described in this embodiment are as follows:

[0040] Solid epoxy resin E12: 35%, toughening agent 860820-S: 25%, liquid epoxy resin E51: 25%, anatase titanium dioxide (molecular formula TiO2): 3%, (dicyandiamide curing agent: LC- 80d: N-p-chlorophenyl N', N'-dimethylurea=1:3:1.5): 12%, 100 parts by weight of dicyandiamide curing agent, imidazole curing agent and urea accelerator As a benchmark, wherein the imidazole curing agent is Catalysts company LC-80d curing agent product, the dosage is 54.55 parts, and the particle size is 700nm; the dicyandiamide curing agent is dicyandiamide produced by Jinan Tianyou Chemical Co., Ltd. 50 μm; the urea accelerator is N-p-chlorophenyl N', N'-dimethylurea, selected from N-p-chlorophenyl N', N' of Xindian Chemical Materials (Shanghai) Co., Ltd. - Dimethylurea.

[0041] The production process is as follows: ① Solid epoxy resin, toughening agent and anatase titanium diox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gel time | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com