Jacket washing, drying and shaping device

A technology for drying and setting clothes, applied in the direction of setting/elongating circular fabrics, textiles and papermaking, fabric surface trimming, etc., can solve the problems of time-consuming and laborious, clothes out of shape, snagging, etc., to facilitate popularization and application, reasonable structure , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

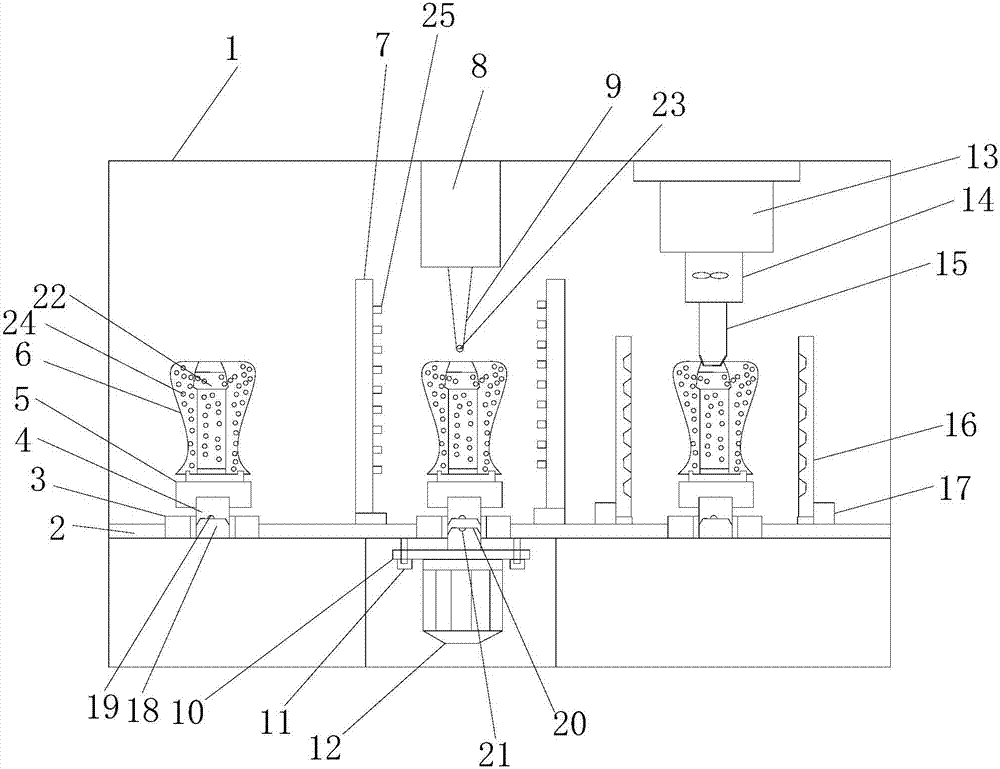

[0018] See attached figure 1 , the present invention a kind of coat cleaning drying sizing device, comprises frame 1, conveying guide rail 2, electric conveying plate 3, rotating clamp shaft 4, fixed chuck 5, setting mold 6, convective spray plate 7, water storage tank 8, Water supply head 9, motor fixed plate 10, lifting cylinder 11, rotating motor 12, lifter 13, blowing hot air blower 14, hot air spray nozzle 15, dehumidification and exhausting air plate 16, exhausting air pump 17, there are many horizontally installed in the described frame 1 A conveying guide rail 2, the conveying guide rails 2 are arranged parallel to each other, a plurality of electric conveying discs 3 are installed on the conveying guide rail 2, a rotating clamping shaft 4 is arranged in the described electric conveying disc 3, and the top of the rotating clamping shaft 4 Connected with a fixed chuck 5, the fixed chuck 5 is clamped with a shaping mold 6, two convective water spray plates 7 are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com