Heat-preservation combined wall of FRP plate and recycled concrete sandwich

A technology of recycled concrete and FRP boards, applied in insulation, walls, building components, etc., can solve problems such as low strength, high price, and inconvenient construction, and achieve the effects of large void ratio, increased recycling, and reduced quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

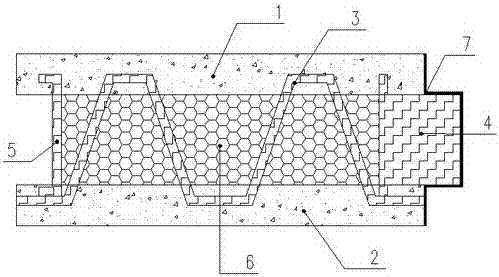

[0026] Example 1: An open-type profiled FRP board and recycled concrete sandwich insulation composite wall.

[0027] 1. See figure 1 Known, it includes recycled concrete outer wall panels (1), recycled concrete inner wall panels (2), open-type FRP panels (3), FRP wall male connectors (4), FRP wall female connectors (5), where the FRP board is placed in the middle of the wall, and the flange (11) of the FRP board is poured in the inner and outer slabs of recycled concrete, in the space separated by the web (12) of the FRP board and the wall board Filled with thermal insulation expanded polystyrene EPS material (6). At the same time, the FRP wall connecting concave and convex parts (4), (5) are placed at both ends of the wall.

[0028] 2. According to the design requirements, determine the pouring thickness of the inner and outer wall panels, the open profile FRP panel (3), the thickness and position of the FRP wall connecting concave and convex parts (4), (5), support the template,...

Embodiment 2

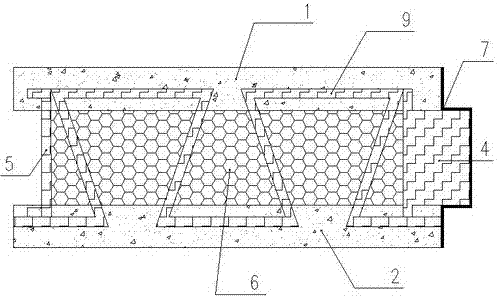

[0032] Example 2: A necking-type pressed FRP board and recycled concrete sandwich insulation composite wall.

[0033] The construction steps of the composite wall are the same as those in Example 1, and it only needs to replace the open-type profiling FRP sheet (3) with a necking-type profiling FRP sheet (9). See figure 2 .

Embodiment 3

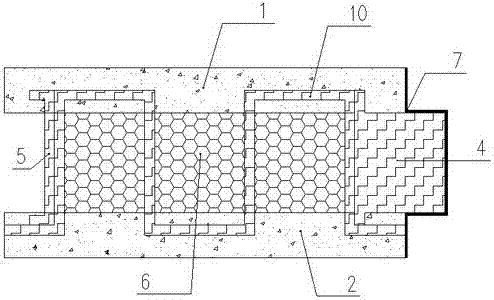

[0034] Example 3: A U-shaped FRP board and recycled concrete sandwich insulation composite wall.

[0035] The construction steps of the composite wall are the same as those in the first embodiment, and only the open-type pressed FRP sheet (3) is replaced with a U-shaped FRP sheet (10). See image 3 .

[0036] FRP materials can also be replaced by organic composite materials such as carbon fiber reinforced composite materials (CFRP), glass fiber reinforced composite materials (GFRP), and aramid fiber reinforced composite materials (AFRP).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com