Kitchen waste and household garbage power generation cooperative treatment technology

A technology for domestic waste incineration and kitchen waste, applied in incinerators, combustion methods, combustion types, etc., can solve problems such as inability to synergize treatment, difficult to incinerate domestic waste, and poor treatment effect, so as to improve waste treatment efficiency, The effect of increasing the utilization rate of waste and reducing the pollution of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

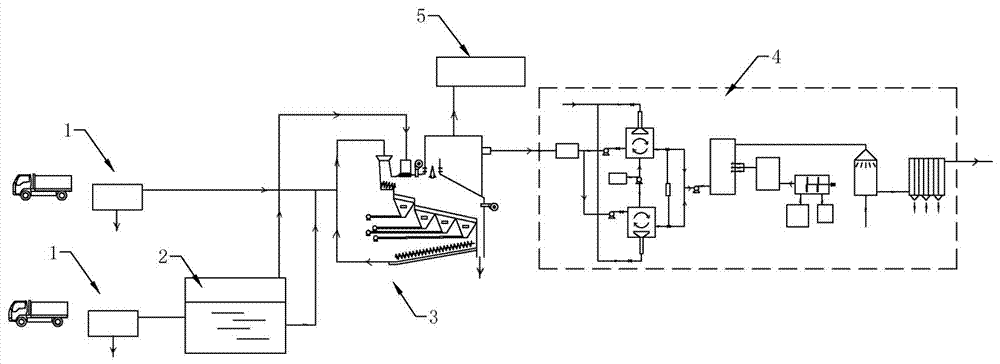

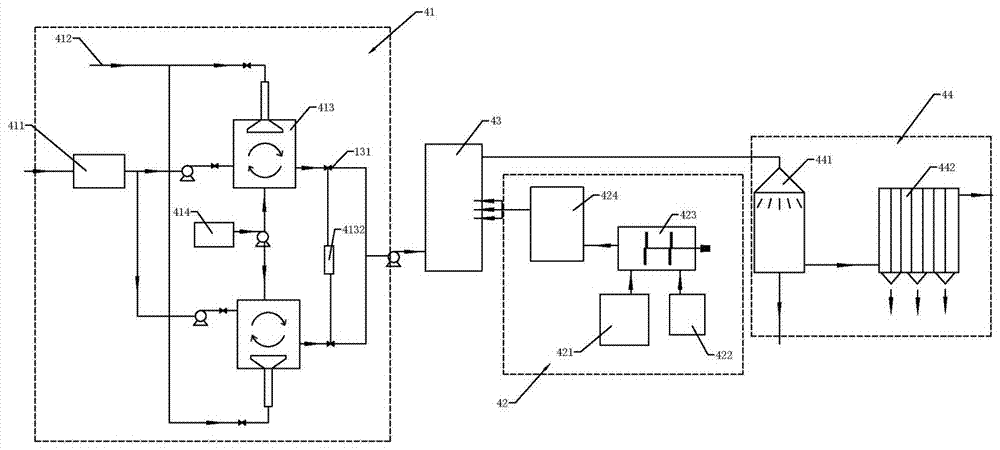

[0035] according to Figure 1 to Figure 3 As shown in the figure, the co-processing process of kitchen waste and domestic waste incineration and power generation mainly adopts the following devices for co-processing: landfill infiltration device 1, biogas generation device 2, incineration device 3, flue gas treatment device 4 and power generation equipment 5; The filter device 1 includes two groups, one group is used for domestic waste treatment, the other group is used for kitchen waste treatment, and the group used for kitchen waste treatment is connected to the biogas generating device 2;

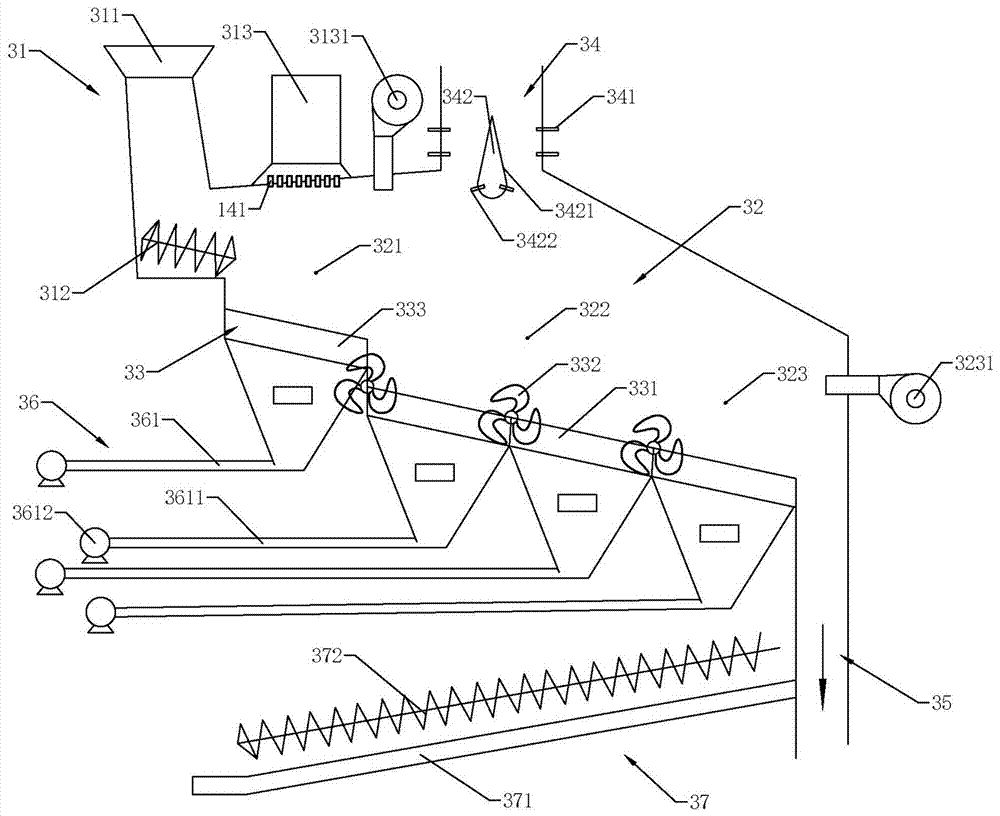

[0036] The incineration device 3 is an incineration boiler, and specifically includes a feeding area 31, a furnace chamber 32, a grate 33, a smoke outlet 34, a slag discharge port 35, an air inlet 36 and a material return device 37. The feeding area 31 includes, hopper 311, The feeder 312 and the biogas inlet 313; the furnace chamber 32 includes a drying area 321, a combustion area 322 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com