Method of measuring thickness of Nd-Fe-B alloy coating

A technology of alloy coating and measurement method, which is applied in measuring devices, instruments, and material analysis through electromagnetic means, can solve the problems of loss of magnetic properties, etc., and achieve the effects of high accuracy, easy operation, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A method for measuring the thickness of an NdFeB magnet coating sample, comprising the steps of:

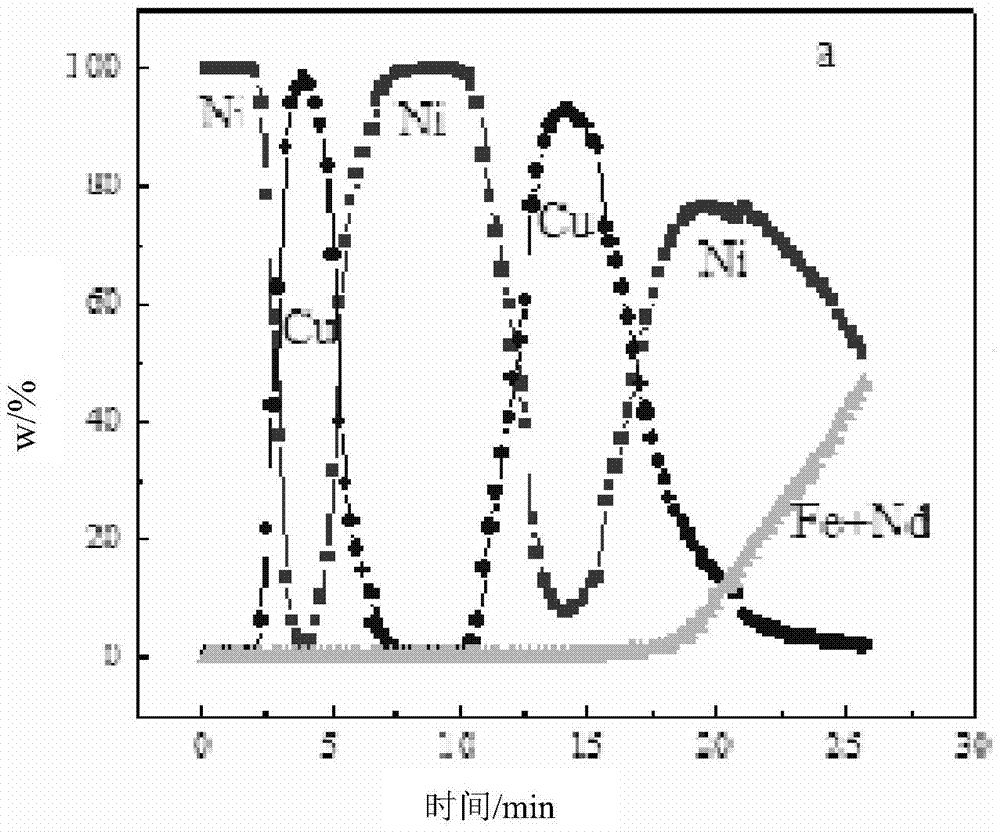

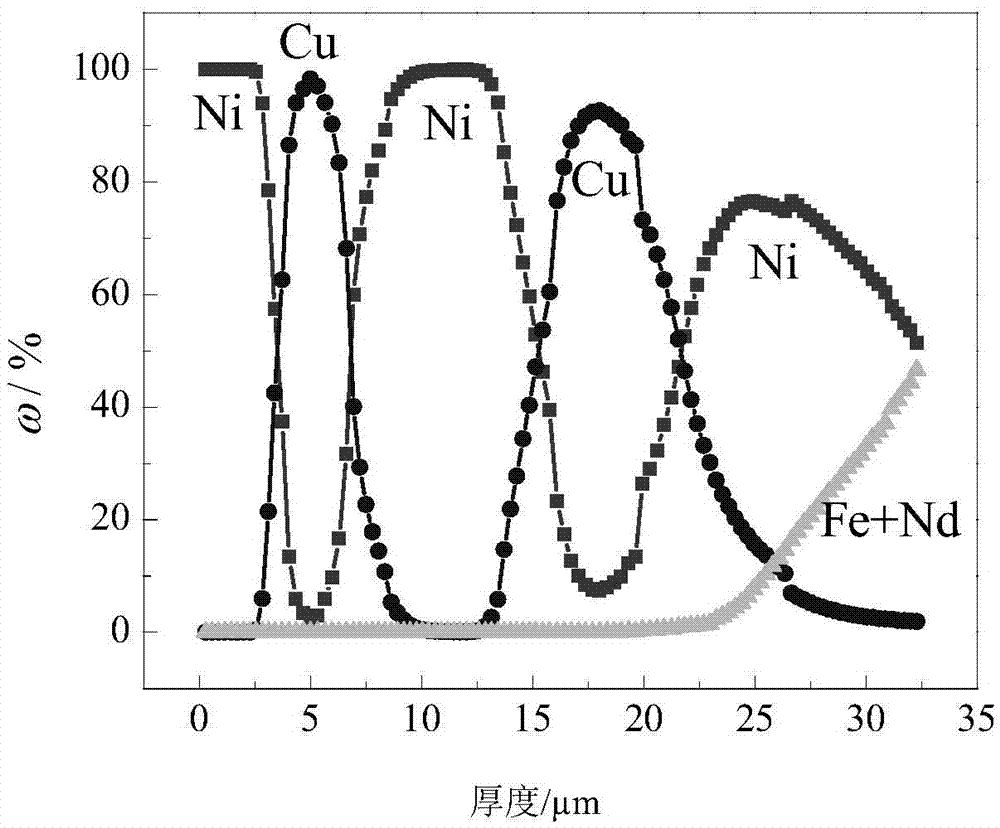

[0024] (1) Wash the surface of the coating with absolute ethanol, and dry it with nitrogen. Glow discharge mass spectrometry (GD-MS) was used to qualitatively measure all elements of the magnet coating sample, and it was roughly determined that the coating type was Ni-Cu-Ni-Cu-Ni composite coating;

[0025] (2) Adjust the GD-MS instrument discharge current to 20mA, discharge gas (Ar) flow rate to 400mL / min, and adopt corresponding lens parameters for each coating, as shown in Table 1;

[0026] Under the above-mentioned instrument conditions, carry out uninterrupted sputtering (i.e. measurement) on the magnet coating, and collect data once every 15 seconds until the content of Fe element rises linearly, indicating that the coating has been broken down, and the test is completed;

[0027] (3) Use the obtained data to draw the element mass fraction-sputtering time distributi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com