Tube cleaner speed control unit

A technology for a pig and an installation ring, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc. It can solve the problems such as the increase of flow loss around the device, and achieve the effect of stable operation, improving the passability of the curve and reducing the local vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The structure of the pig speed control device of the present invention will be further described through the embodiments and in conjunction with the accompanying drawings. In the following embodiments, programmable logic controllers, encoders, and stepper motors are purchased from the market.

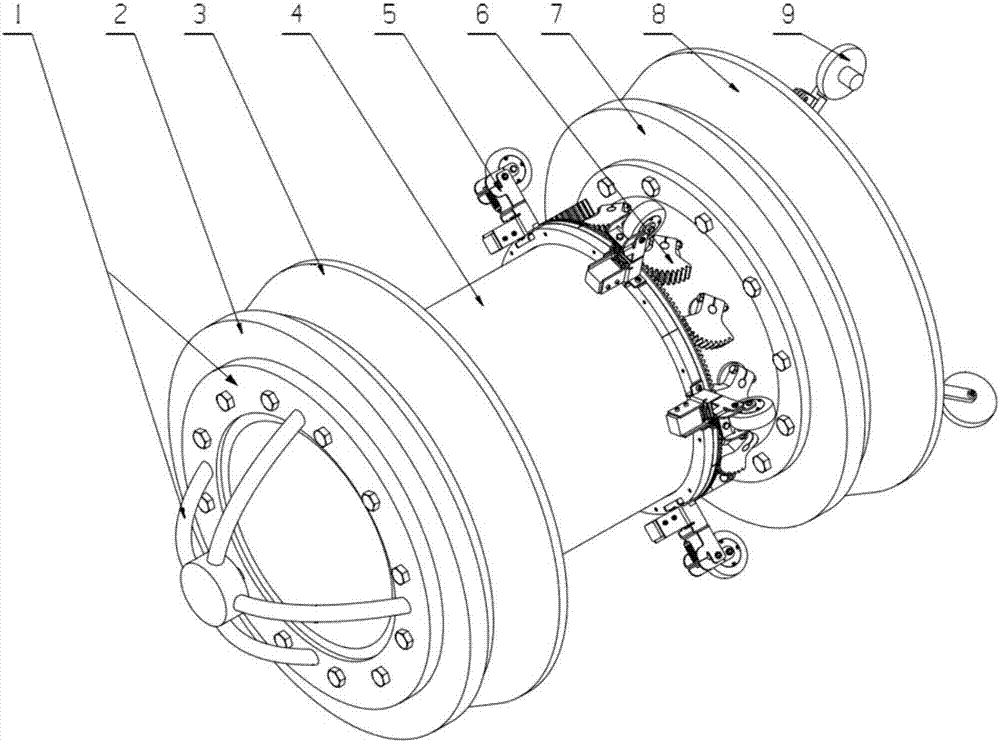

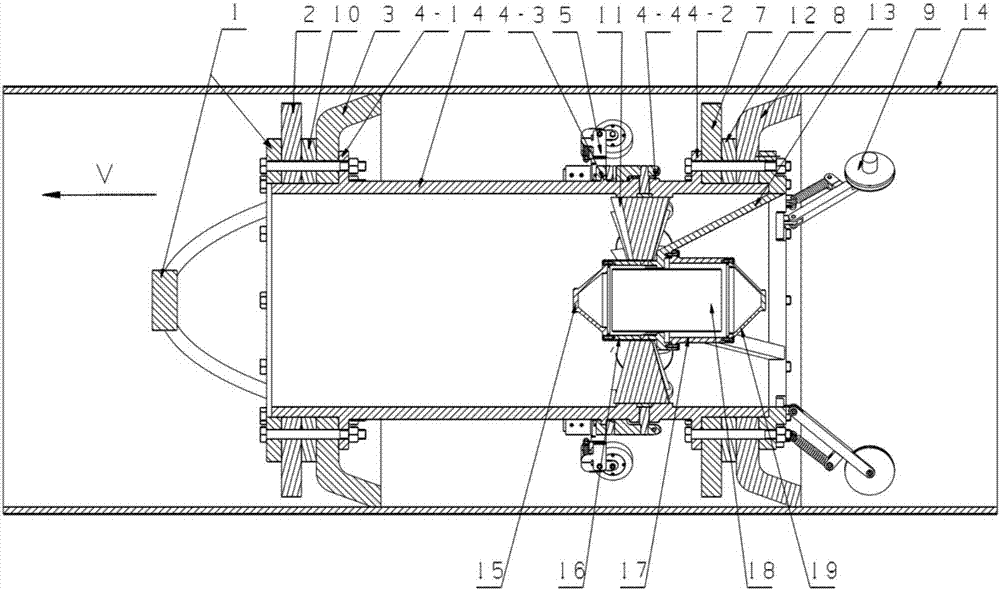

[0046] In this embodiment, the pig speed control device such as figure 1 , figure 2 As shown, it includes outer skeleton 4, inner skeleton 13, anti-collision support 1, front cup assembly, rear cup assembly, mileage wheel assembly 9, speed control rotary valve, control system 18 and a sealed chamber for placing the control system.

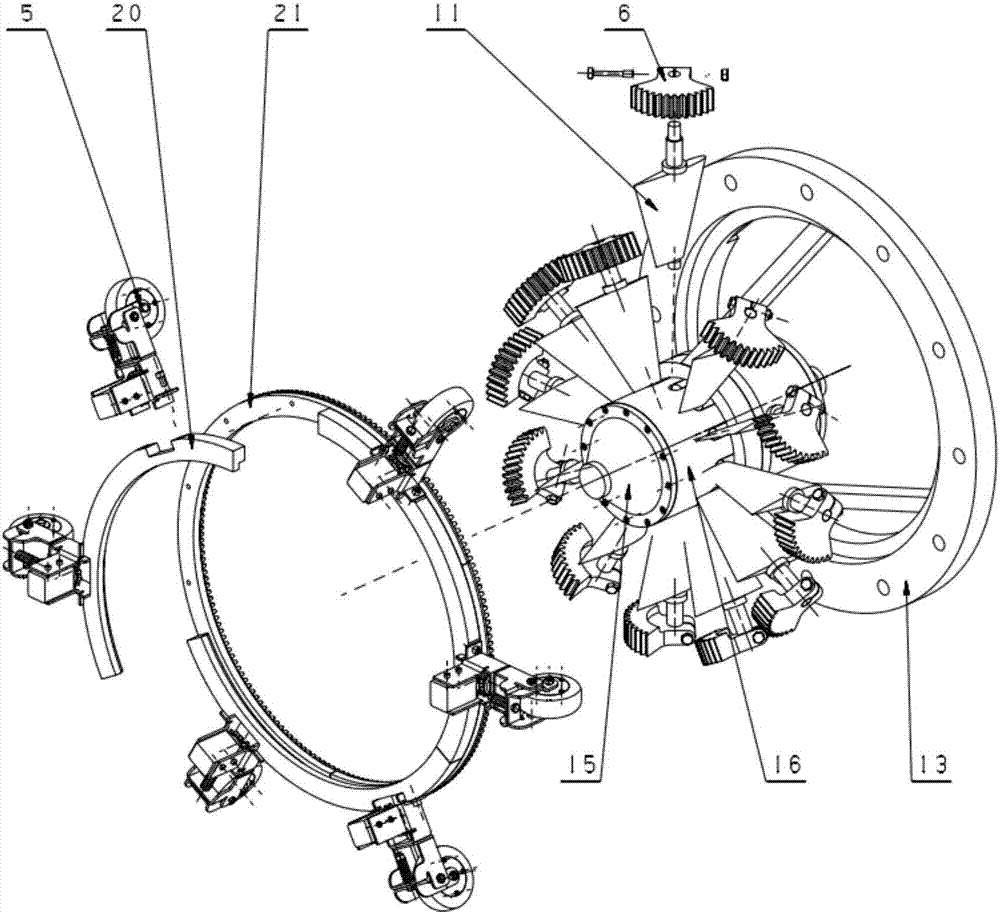

[0047] The speed control rotary valve is as image 3 As shown, it is composed of movable airfoil fan blade 11 and a circumferential control mechanism; movable airfoil fan blade 11 is as Figure 7 , Figure 8 , Figure 9 As shown, by the airfoil blade 11-4 and the first journal 11-5 positioned at one end of the airfoil blade 11-4, the collar 11-3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com