Dual-conical-surface supporting rotary tool device

A double-cone surface and tool technology, which is used in the manufacture of tools, transmission devices, gear transmission devices, etc., can solve the problems of low grinding line speed, loss of precision, and excessive tool wear, so as to improve tool life and processing efficiency, The effect of high error homogenization and increased machining line speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

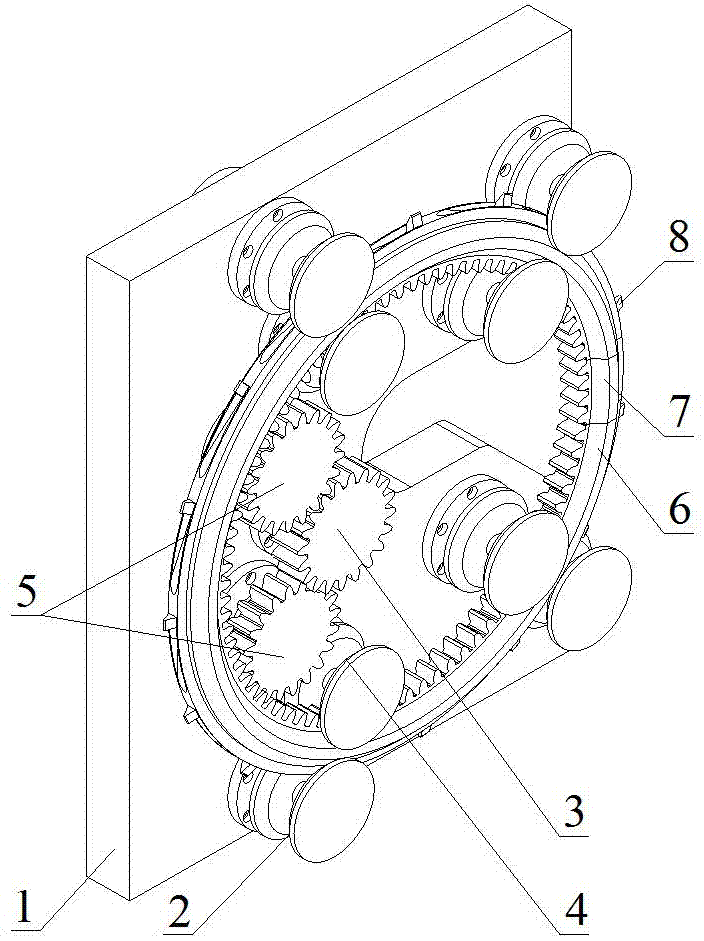

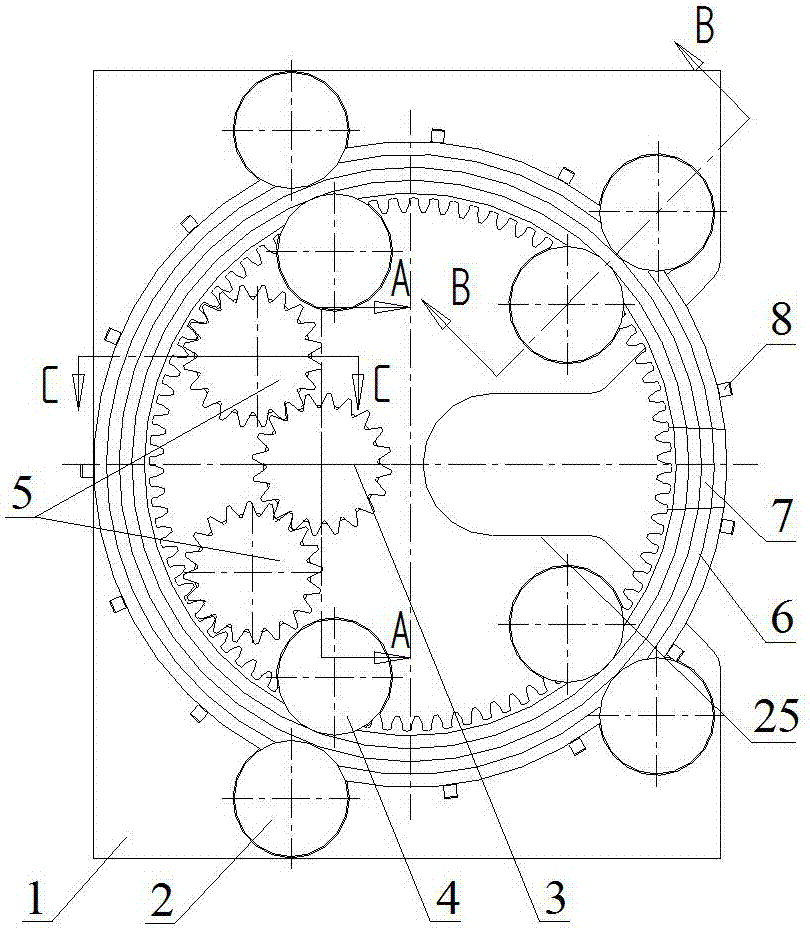

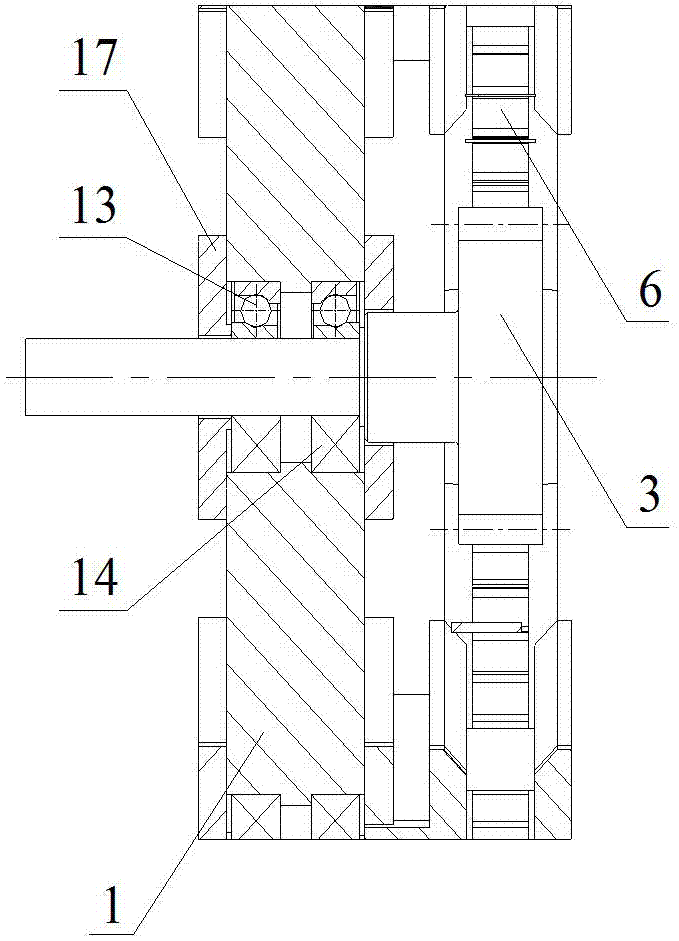

[0021] exist Figure 1-5 In the shown embodiment: including bracket 1, outer rotation support wheel shaft 2, rotation drive gear shaft 3, inner rotation support wheel shaft 4, idler shaft 5, inner gear frame 6, plug 7, tool head 8, outer left bearing 9 , Outer right bearing 10, inner right bearing 11, inner left bearing 12, left bearing 13, right bearing 14, upper end cover 15, lower end cover 16, middle end cover 17, lower bearing 18, upper bearing 19, idler end cover 20, The outer raceway 21, the inner raceway 22, the outer roller raceway 23, the inner roller raceway 24 and the open groove 25, wherein the outer rotation support wheel shaft 2 is positioned and supported on the bracket by the outer left bearing 9, the outer right bearing 10 and the upper end cover 15 1, the inner rotation support wheel shaft 4 is positioned and supported on the bracket 1 through the inner right bearing 11, the inner left bearing 12 and the lower end cover 16, and the rotation driving gear shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com