Shield tail sealing oil of shield machine as well as preparation method and application of shield tail sealing oil

A shield tail sealing and grease technology, which is applied in the oil/fat refining, fat production, petroleum industry, etc., can solve the problems of poor sealing performance of shield sealing grease, lack of solutions, and large amount of grease, etc., and achieves low cost and reduced cost. The effect of production cost and usage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

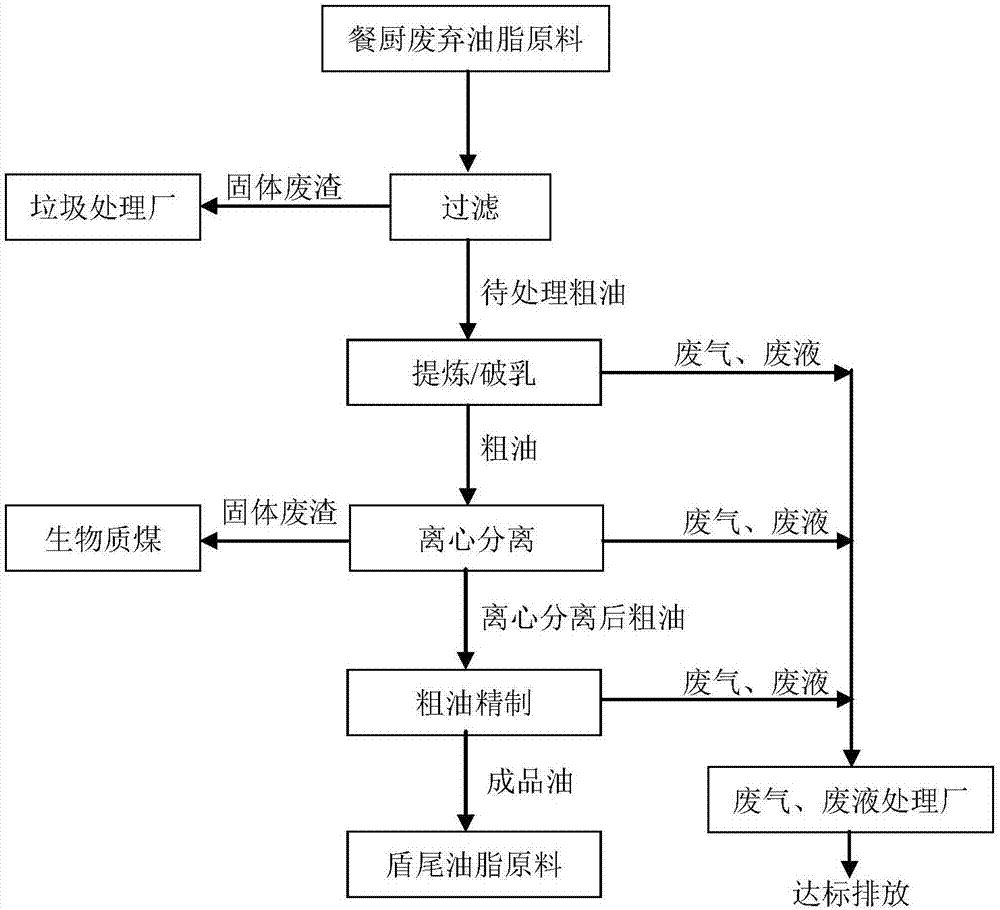

Method used

Image

Examples

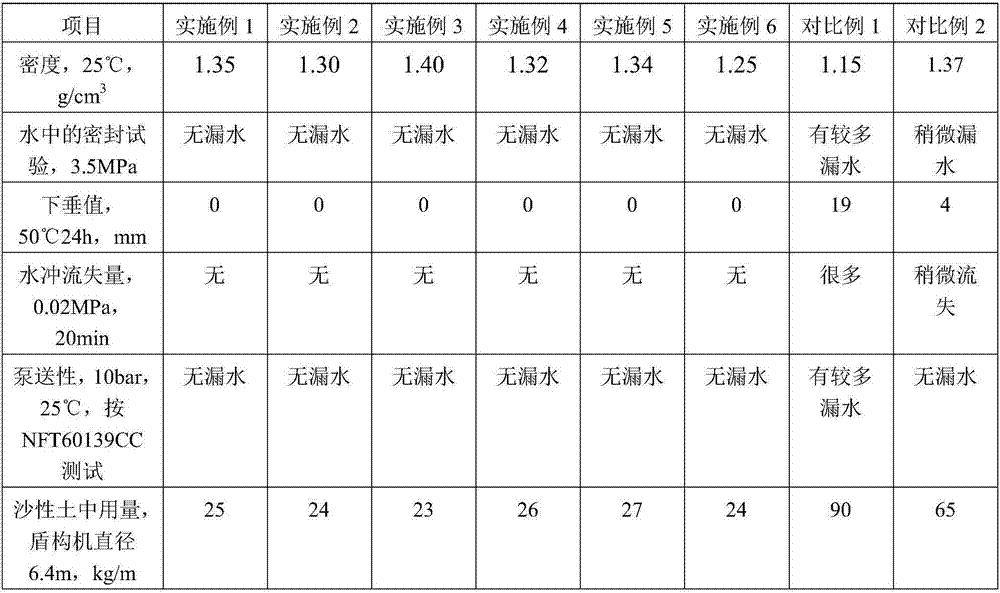

Embodiment 1

[0058] The components of shield tail seal grease are: 150kg of deep-processed waste oil, 10kg of agar, 40kg of gum arabic, 8kg of antifungal agent, 5kg of lubricant, 400kg of light calcium carbonate powder, and 38kg of bamboo fiber.

[0059] Preparation method: After mixing the deep-processed waste oil and bamboo fiber, stir for 20 minutes, then add 10kg of agar, 40kg of gum arabic, antifungal agent and lubricating oil to it, stir for 20 minutes, then add light calcium carbonate powder in batches during the stirring process (A small amount of continuous addition is required when adding), stirring for no less than 76 minutes until a uniform yellow viscous mixture is obtained.

Embodiment 2

[0061] The components of shield tail seal grease are: 130kg of deep-processed waste oil, 15kg of carrageenan, 45kg of agar, 12kg of antifungal agent, 6kg of lubricant, 330kg of mica powder, and 42kg of bamboo fiber.

[0062] Preparation method: After mixing the deep-processed waste oil and bamboo fiber, stir for 20 minutes, then add carrageenan, agar, anti-fungal agent and lubricating oil therein, after stirring for 20 minutes, add mica powder in batches during the stirring process (a small amount is required when adding Continuous addition), stirring for no less than 70 minutes, until a uniform yellow viscous mixture is obtained.

Embodiment 3

[0064] The components of shield tail seal grease are: 130kg of deep-processed waste oil, 15kg of alginic acid, 45kg of agar, 12kg of antifungal agent, 6kg of lubricant, 130kg of mica powder, 200kg of light calcium carbonate powder, and 42kg of bamboo fiber.

[0065] Preparation method: After mixing deep-process waste oil and bamboo fiber, stir for 15 minutes, then add alginic acid, agar, anti-fungal agent and lubricating oil to it, after stirring for 20 minutes, add mica powder and light calcium carbonate in batches during the stirring process powder (a small amount of continuous addition is required when adding), stirring for no less than 70 minutes until a uniform yellow viscous mixture is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com