Preparation method for steel ball sample and testing method for Rockwell hardness of steel ball

A technology of Rockwell hardness and test method, which is applied in the Rockwell hardness test of steel balls and the field of sample preparation of steel ball samples, which can solve problems such as unevenness, failure to meet the requirements of the hardness test, and grease.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

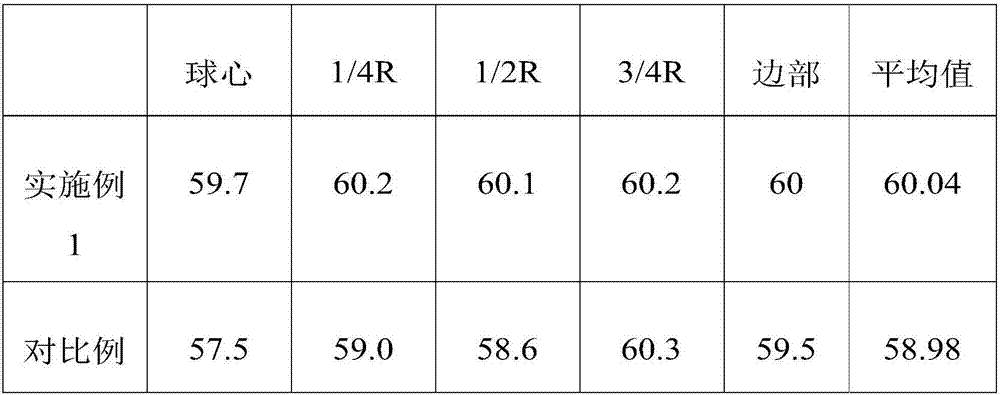

Embodiment 1

[0024] The invention discloses a sample preparation method of a steel ball sample. The steel ball is cut by wire cutting, and the processed steel ball includes a first grinding surface and a second grinding surface opposite to each other. The first grinding surface was ground several times by using an abrasive belt grinding machine to form the test surface of the steel ball. The grinding method was followed by rough grinding, fine grinding, and fine grinding in sequence. The grain size of the abrasive belt for coarse grinding is 50 mesh, until the metallic luster is completely exposed; the grain size of the abrasive belt for fine grinding is 220 mesh, until the first grinding surface is flat and smooth; the grain size of the abrasive belt for fine grinding is 800 mesh, Until the first grinding surface is flat and smooth without grinding marks. After the grinding is completed, the first grinding surface is the surface where the center of the steel ball is located. Grind the se...

Embodiment 2

[0027] The invention discloses a sample preparation method of a steel ball sample. The steel ball after being cut and processed by wire cutting includes a first grinding surface and a second grinding surface opposite to each other. The first grinding surface was ground several times by using an abrasive belt grinding machine to form the test surface of the steel ball. The grinding method was followed by rough grinding, fine grinding, and fine grinding in sequence. The grain size of the abrasive belt for rough grinding is 40 mesh, until the metallic luster is completely exposed; the grain size of the abrasive belt for fine grinding is 230 mesh, until the first grinding surface is flat and smooth; the grain size of the abrasive belt for fine grinding is 780 mesh, Until the first grinding surface is flat and smooth without grinding marks. After the grinding is completed, the first grinding surface is the surface where the center of the steel ball is located. Grind the second gri...

Embodiment 3

[0030]The invention discloses a sample preparation method of a steel ball sample. The steel ball is cut by wire cutting, and the processed steel ball includes a first grinding surface and a second grinding surface opposite to each other. The first grinding surface was ground several times by using an abrasive belt grinding machine to form the test surface of the steel ball. The grinding method was followed by rough grinding, fine grinding, and fine grinding in sequence. The grain size of the abrasive belt for coarse grinding is 60 mesh, until the metallic luster is completely exposed; the grain size of the abrasive belt for fine grinding is 200 mesh, until the first grinding surface is flat and smooth; the grain size of the abrasive belt for fine grinding is 820 mesh, Until the first grinding surface is flat and smooth without grinding marks. After the grinding is completed, the first grinding surface is the surface where the center of the steel ball is located. Grind the sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com