Experimental device and method for energy-gathering miscible fluid and rock mass cracking reaction flow

A technology of miscible fluid and cracking reaction, which is applied in measuring devices, mining fluids, earthwork drilling, etc., can solve the problems of low cracking efficiency and single function, and achieve the effect of improving the displacement effect and regulating the permeability of the core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Below in conjunction with accompanying drawing and embodiment describe in detail:

[0055] 1. Device

[0056] 1. Overall

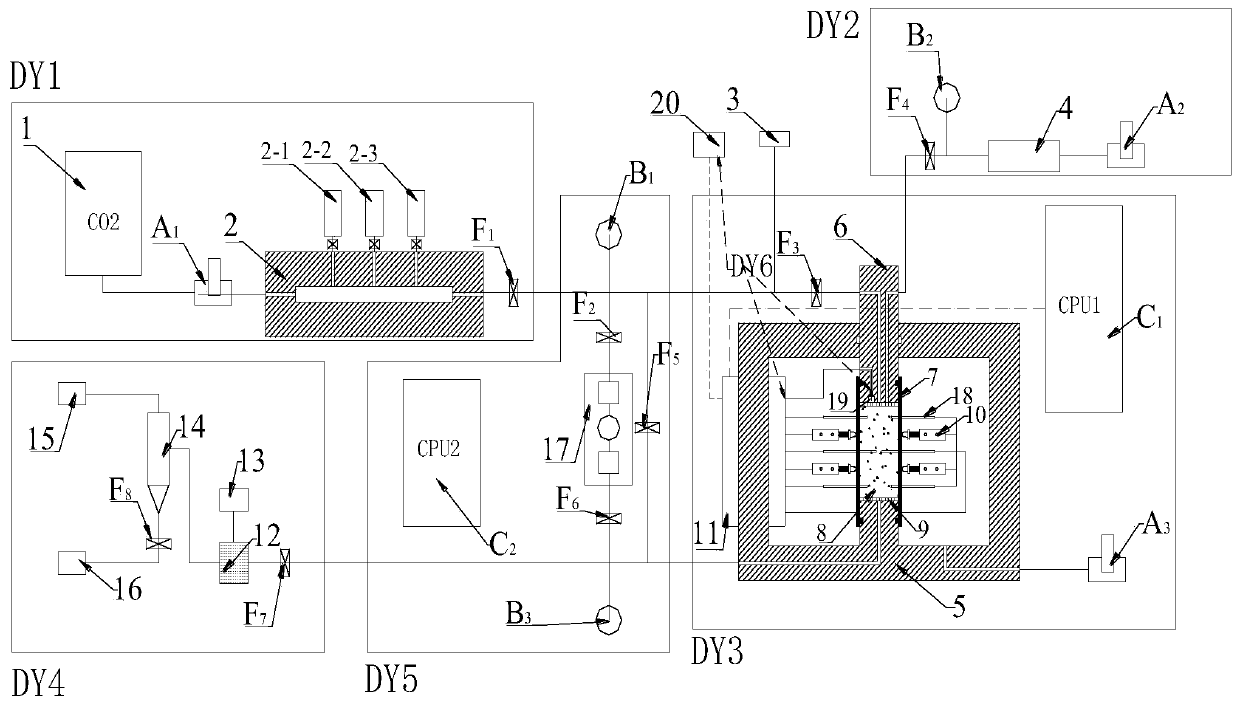

[0057] This device consists of CO2-based nano energy-gathering miscible fluid generation unit DY1, mineral storage fluid simulation generation unit DY2, conventional triaxial stress loading unit DY3, gas-solid-liquid separation unit DY4, temperature-seepage measurement unit DY5 and spark ignition control unit DY6 composition;

[0058] The CO2-based nano energy-gathering miscible fluid generation unit DY1, the mineral storage fluid simulation generation unit DY2, the gas-solid-liquid separation unit DY4, the temperature-seepage measurement unit DY5 and the spark ignition control unit DY6 are respectively connected with the conventional triaxial stress loading unit DY3, Conduct CO2-based nano-energy-gathering miscible fluid and reservoir rock pyrolysis reaction-flow-stress coupling experiment;

[0059] 1) The CO2-based nano-energy mixed-phase fluid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com