Method of forecasting quality of molten iron of blast furnace and system thereof

A blast furnace molten iron and forecasting system technology, applied in blast furnaces, blast furnace details, manufacturing computing systems, etc., can solve problems such as reduced prediction accuracy, impact on prediction accuracy, static models unable to adapt to sample changes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

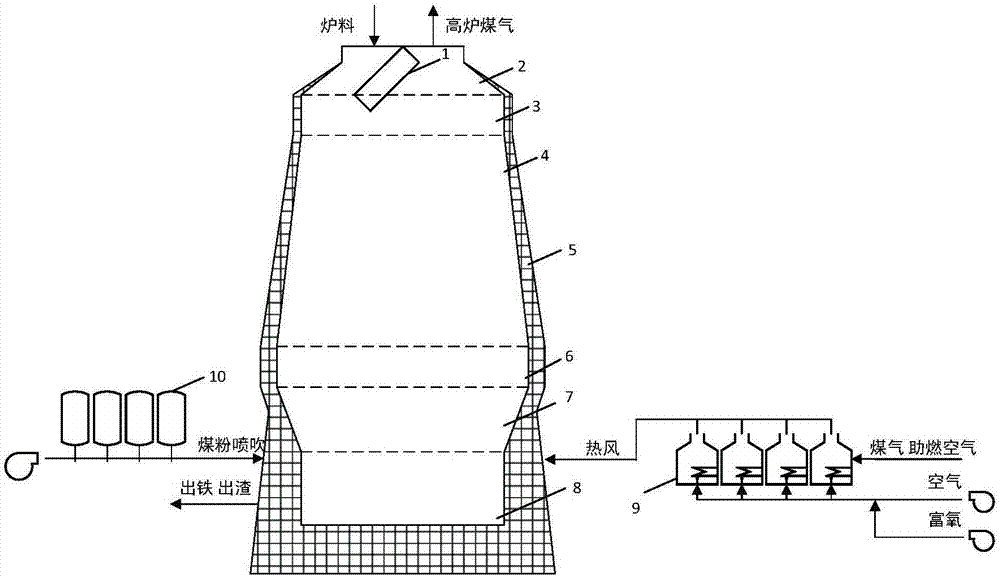

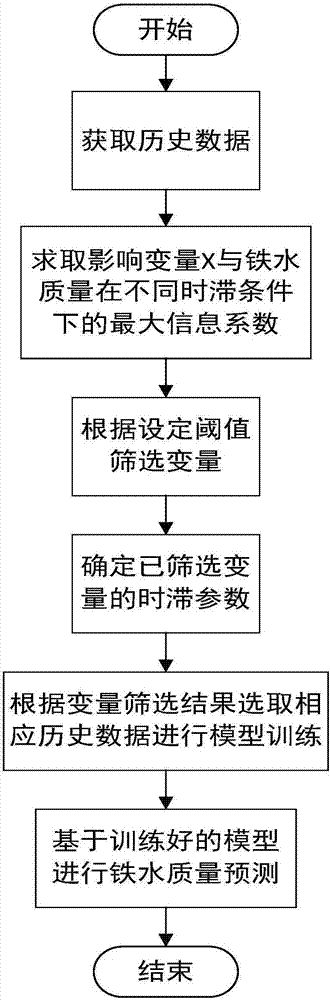

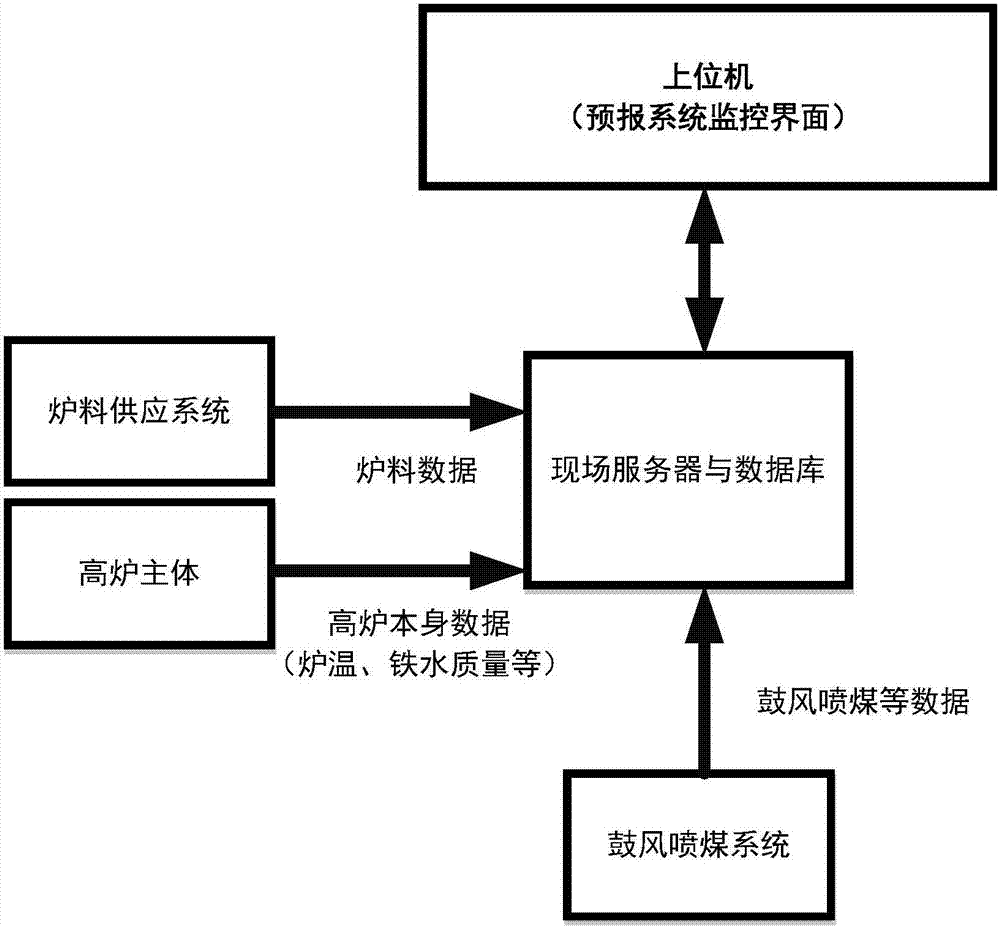

[0043] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

[0044] In a preferred embodiment of the present invention, a method for predicting the quality of blast furnace molten iron is provided, and the method is used to predict the quality of molten iron in the process of blast furnace ironmaking. The blast furnace molten iron quality prediction method of the present embodiment comprises the following steps:

[0045] Step 1: Combining the actual measurable or calculable variables of the No. 2 blast furnace of a steel plant, the mechanism analysis was carried out, and 24 influencing variables related to the silicon content of the blast furnace molten iron were finally determined: X 1 - Cooling air flow, X 2 - air supply ratio, X 3 - hot air pressure, X 4 --Furnace top pressure, X 5 - differential pressure, X 6 -Top pressure air volume ratio, X 7 - Breathability, X 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com