Water-in-oil type oil composition and preparation method thereof

An oil composition and a technology for the composition, which are applied in the directions of edible oil/fat, food science, application, etc., can solve the problems of complicated operation, greasy taste, limited improvement effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The preparation method of the oil phase composition includes: heating and melting the oil, adding an emulsifier, stirring evenly, preferably stirring for at least 30 minutes, quenching, kneading, and aging at 0-30°C for 3-7 days to obtain oil phase composition.

[0049] water phase composition

[0050] The aqueous phase composition includes water and additives.

[0051] The additives include sugar and / or flavor substances, preferably, the additives are sugar.

[0052] In a specific embodiment of the application, the aqueous phase composition includes:

[0053] Sugar: 15-35%, as a non-limiting example, including granulated sugar (such as white granulated sugar - the main component of the national standard is sucrose, or red granulated sugar, the main component of the national standard is sucrose + reducing sugar, such as glucose, fructose, galactose, lactose , maltose, etc.) and / or syrup (syrup is a viscous, high-concentration sugar solution made by boiling or other t...

Embodiment

[0107] Embodiment preparation method:

[0108] 1. Preparation of oil phase composition:

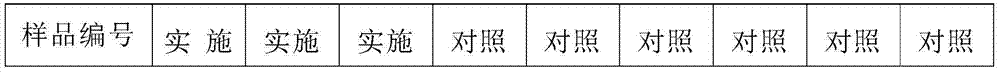

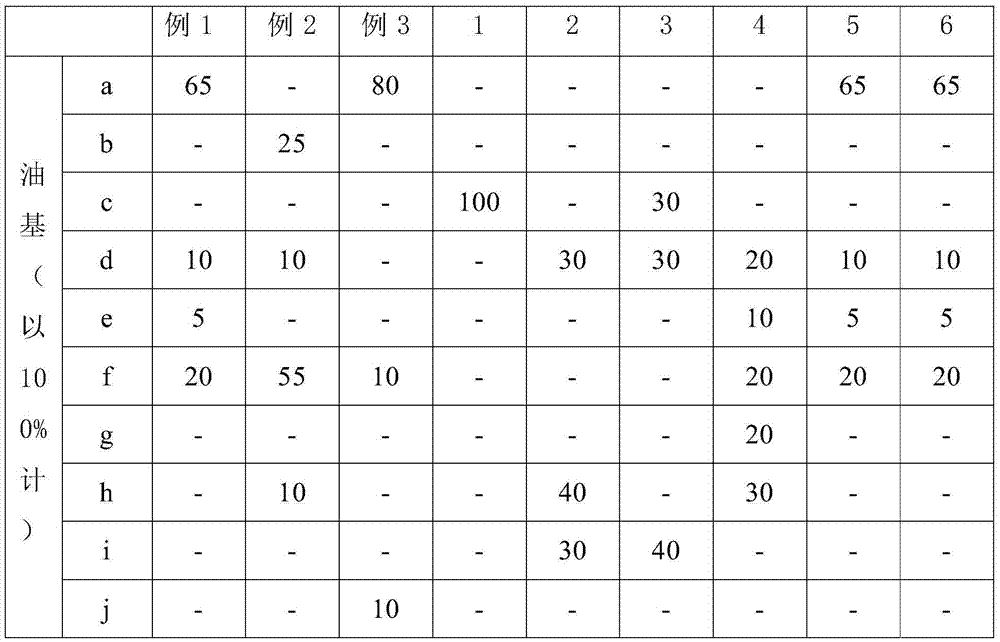

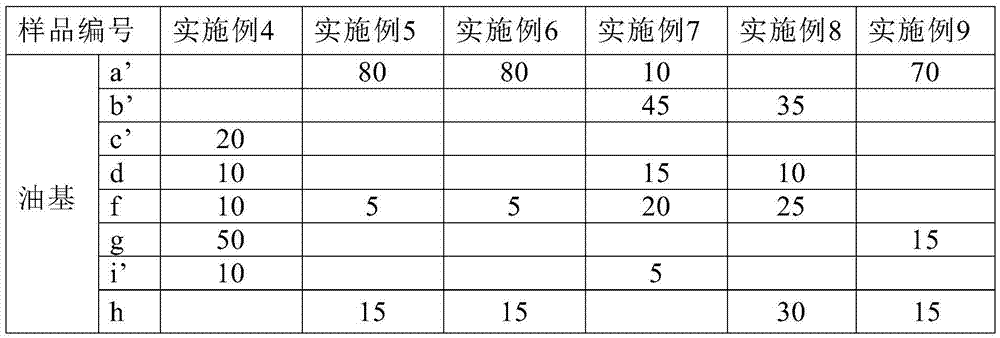

[0109] Prepare the oil phase composition according to the examples and comparisons shown in the above Table 1. The preparation method is: add the oil and emulsifier into the emulsification tank, emulsify for 30 minutes at 60°C, undergo rapid cooling, kneading, and then place the oil sample in After aging for 5 days under the condition of 0-10° C., the oil phase composition sample (fat sample for short) was prepared.

[0110] 2. Preparation of water-in-oil type oil composition:

[0111] Whisk the oil phase composition at medium speed for 25s with an egg beater, the whipping device is (Shenzhen Sirida, AR005, paddle type stirring head), the whipping speed is 627rpm, and slowly add the water phase combination while beating the oil phase at high speed (Mix the water and the sugar, milk powder and essence in the table evenly to obtain the water phase composition). After adding the water phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com