Beryllium-containing ceramic precursor preparation method

A ceramic precursor, beryllium acetone technology, applied in the field of polymer material preparation, can solve the problems of difficult large-scale production and application, high cost, etc., and achieve the effect of meeting the requirements of industrial production, low cost, and reduced growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

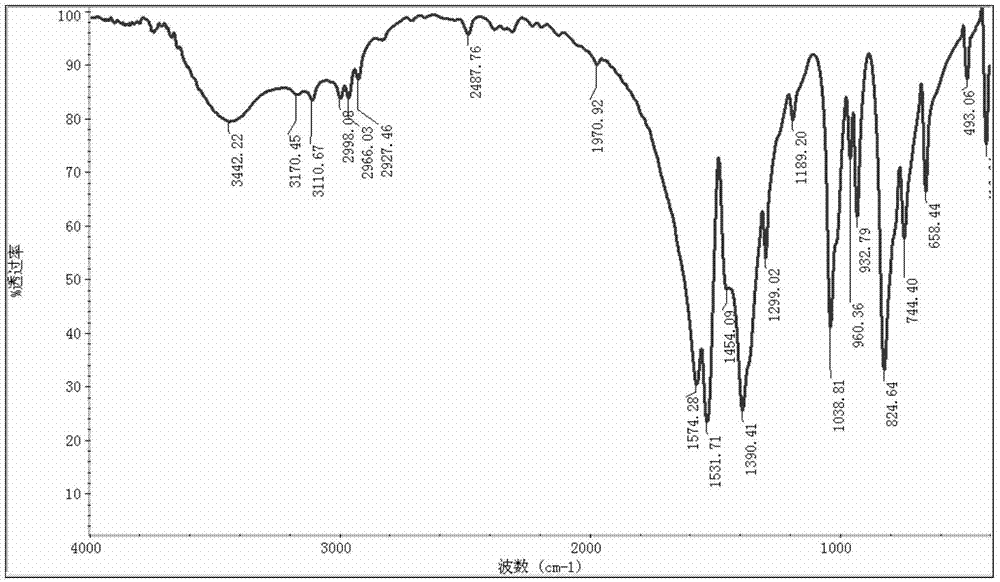

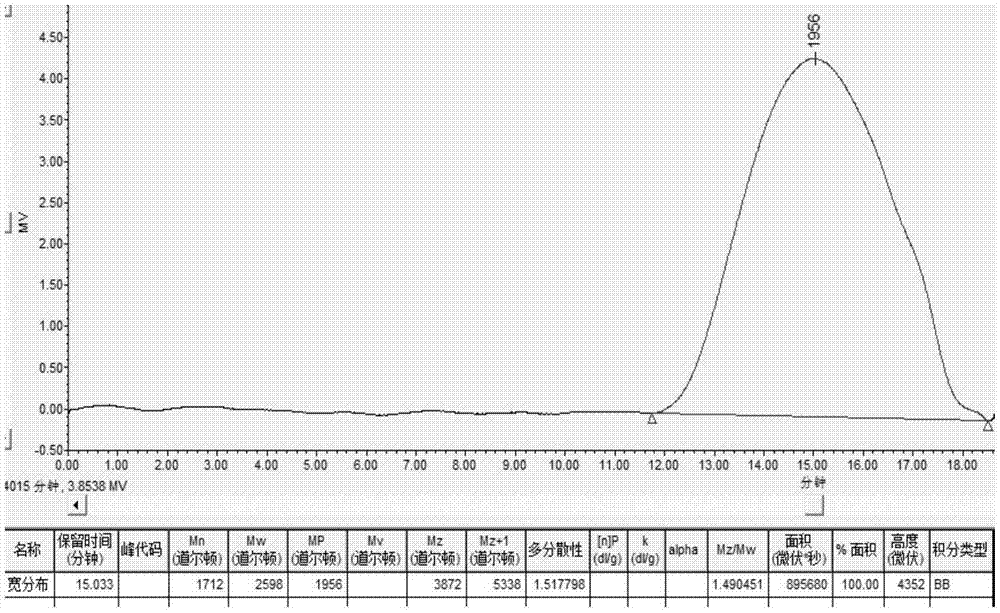

[0031] Add 100 g of polycarbosilane (softening point 146-168° C., number average molecular weight 1200-1300), 20 g of beryllium acetylacetonate (20%), and toluene in sequence into a three-necked flask equipped with mechanical stirring, and stir to make the reaction liquid clear and transparent. After the solvent was distilled off by heating, the temperature of the reaction solution was raised to 180° C. under the protection of nitrogen, and the reaction was carried out for 16 hours. An orange-yellow transparent resinous product was obtained with a yield of 98%, a softening point of 200-210° C., a number-average molecular weight Mn=1956, and a molecular weight distribution α=1.52.

[0032] The resulting product contains beryllium silicon carbide infrared spectrum see figure 1 , sol-gel chromatogram (GPC spectrum) see figure 2 . Example 2

Embodiment 2

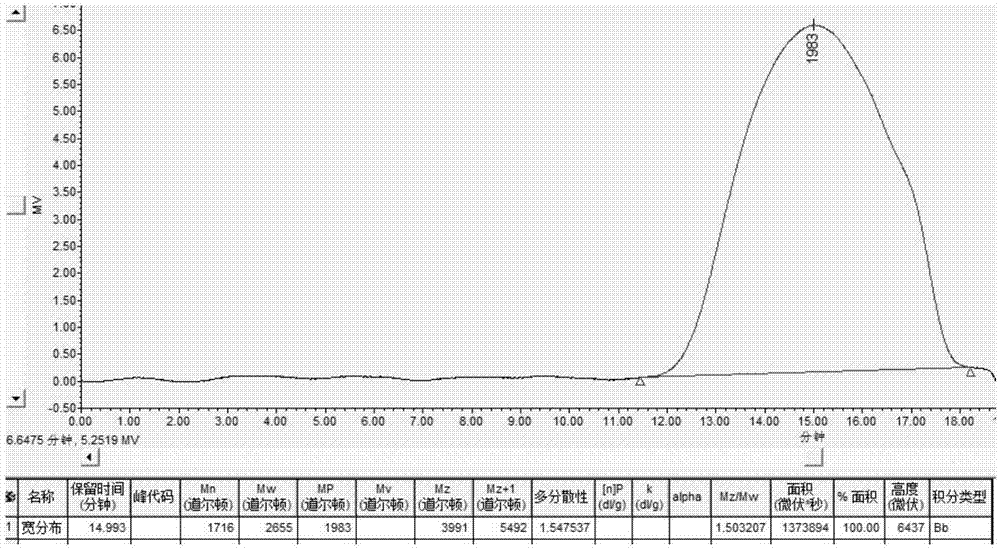

[0033] Add 100 g of polycarbosilane (softening point 196-210° C., number average molecular weight 1300-1460), 20 g of beryllium acetylacetonate (20%), and toluene into a three-necked flask equipped with mechanical stirring, and stir to make the reaction liquid clear and transparent. After the solvent was distilled off by heating, the temperature of the reaction solution was raised to 180° C. under the protection of nitrogen, and the reaction was carried out for 18 hours. An orange-yellow transparent resinous product was obtained with a yield of 96%, a softening point of 210-220° C., a number-average molecular weight Mn=1983, and a molecular weight distribution α=1.55.

[0034] Gained beryllium-containing silicon carbide product sol-gel chromatogram (GPC spectrum) see image 3 .

Embodiment 3

[0036] Add 100 g of polycarbosilane (softening point 218-240° C., number average molecular weight 1300-1710), 20 g of beryllium acetylacetonate (20%), and toluene in sequence into a three-neck flask equipped with mechanical stirring, and stir to make the reaction solution clear and transparent. After the solvent was distilled off by heating, the temperature of the reaction solution was raised to 180° C. under the protection of nitrogen, and the reaction was carried out for 15 hours. An orange-yellow transparent resinous product was obtained with a yield of 98%, a softening point of 230-260° C., a number-average molecular weight Mn=3805, and a molecular weight distribution а=2.28.

[0037] Gained beryllium-containing silicon carbide product sol-gel chromatogram (GPC spectrum) see Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com