Coining floor

A technology of slag layer and concrete layer, applied in the field of embossed floor and its preparation, can solve the problems of high maintenance cost, short service life, poor aesthetics, etc., achieve strong decorative and cultural and artistic connotations, long service life, good aesthetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

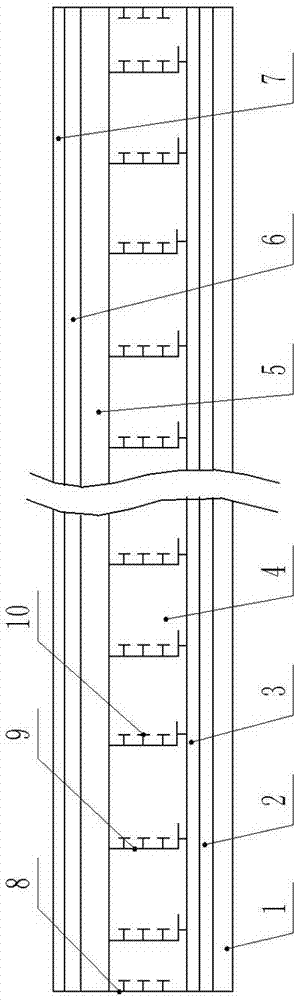

[0040] Such as figure 1 As shown, the embossed floor includes a bottom slag layer 1 as the base layer, and the upper part of the bottom slag layer 1 is successively laid with an emery layer 2, a polyethylene reinforced mesh layer 3, an ecological concrete layer 4, a graded crushed stone layer 5, two Grade concrete layer 6 and epoxy resin layer 7.

[0041] Wherein, the thickness of the bottom slag layer 1 is 5mm, the cost is low, and the pressure resistance is strong.

[0042] Wherein, the thickness of the corundum layer 2 is 5 mm, which has high structural strength and strong bearing capacity.

[0043] Wherein, the polyethylene reinforcing net layer 3 has a thickness of 5mm, which can improve the overall structural strength.

[0044] Wherein, the thickness of the ecological concrete layer 4 is 20mm, and the ecological concrete layer 4 is not easily deformed.

[0045] Among them, the thickness of the graded crushed stone layer 5 is 6 mm, which has high structural strength, s...

Embodiment 2

[0066] The difference between this embodiment and Embodiment 1 is that the structure of the embossed floor is inconsistent. The embossed floor includes the bottom slag layer 1 as the base layer, and the upper part of the bottom slag layer 1 is successively laid with a carborundum layer 2 and a polyethylene reinforcement mesh. Layer 3, ecological concrete layer 4, graded gravel layer 5, secondary concrete layer 6 and epoxy resin layer 7.

[0067] Wherein, the thickness of the bottom slag layer 1 is 10mm, the cost is low, and the pressure resistance is strong.

[0068] Wherein, the thickness of the corundum layer 2 is 15mm, which has high structural strength and strong bearing capacity.

[0069] Wherein, the polyethylene reinforcing net layer 3 has a thickness of 12 mm, which can improve the overall structural strength.

[0070] Wherein, the thickness of the ecological concrete layer 4 is 50 mm, and the ecological concrete layer 4 is not easily deformed.

[0071] Among them, t...

Embodiment 3

[0078] The difference between this embodiment and Embodiment 1 is that the structure of the embossed floor is different. The embossed floor includes the bottom slag layer 1 as the base layer, and the upper part of the bottom slag layer 1 is successively laid with emery layer 2, polyethylene reinforced Mesh layer 3, ecological concrete layer 4, graded gravel layer 5, secondary concrete layer 6 and epoxy resin layer 7.

[0079] Wherein, the thickness of the bottom slag layer 1 is 8mm, the cost is low, and the pressure resistance is strong.

[0080] Wherein, the thickness of the corundum layer 2 is 10 mm, which has high structural strength and strong bearing capacity.

[0081] Wherein, the polyethylene reinforcing net layer 3 has a thickness of 10 mm, which can improve the overall structural strength.

[0082] Wherein, the thickness of the ecological concrete layer 4 is 30 mm, and the ecological concrete layer 4 is not easily deformed.

[0083] Among them, the thickness of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com