Plasma processing device and adjustment method for improving etching symmetry

A processing device and plasma technology, applied in the direction of circuits, discharge tubes, electrical components, etc., can solve the problems of symmetry of etching rate, asymmetry of etching results, asymmetry of etching and other problems, so as to improve the asymmetry of etching , Improve the etching symmetry, and improve the effect of product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

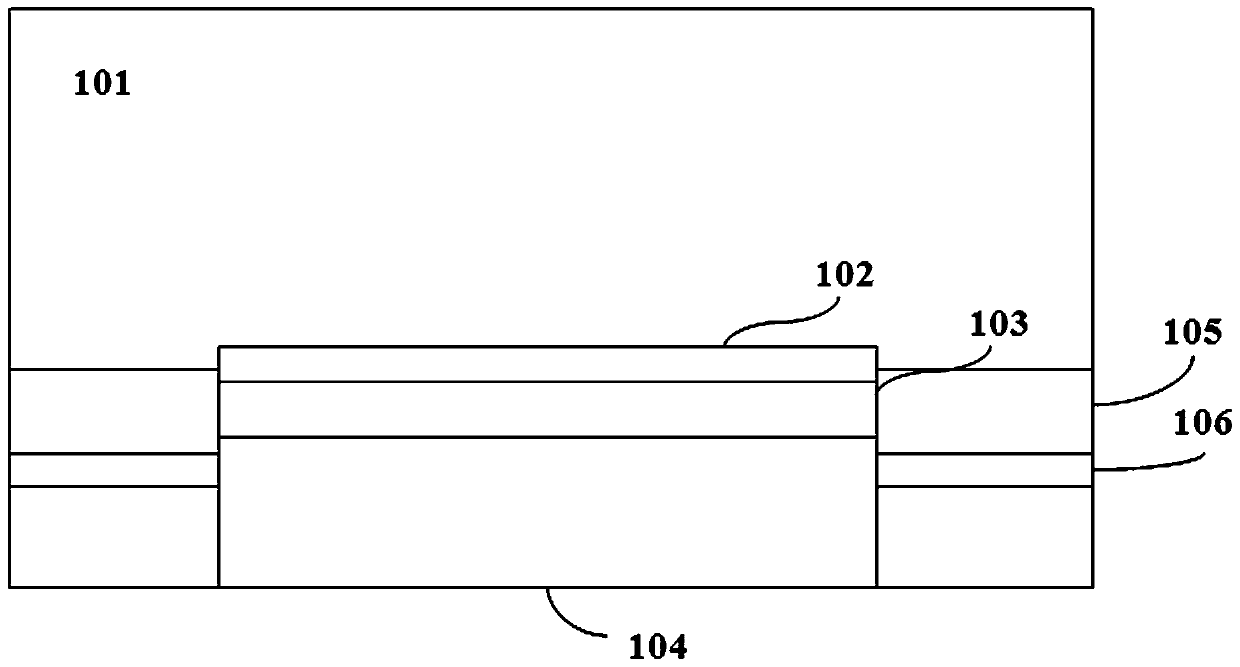

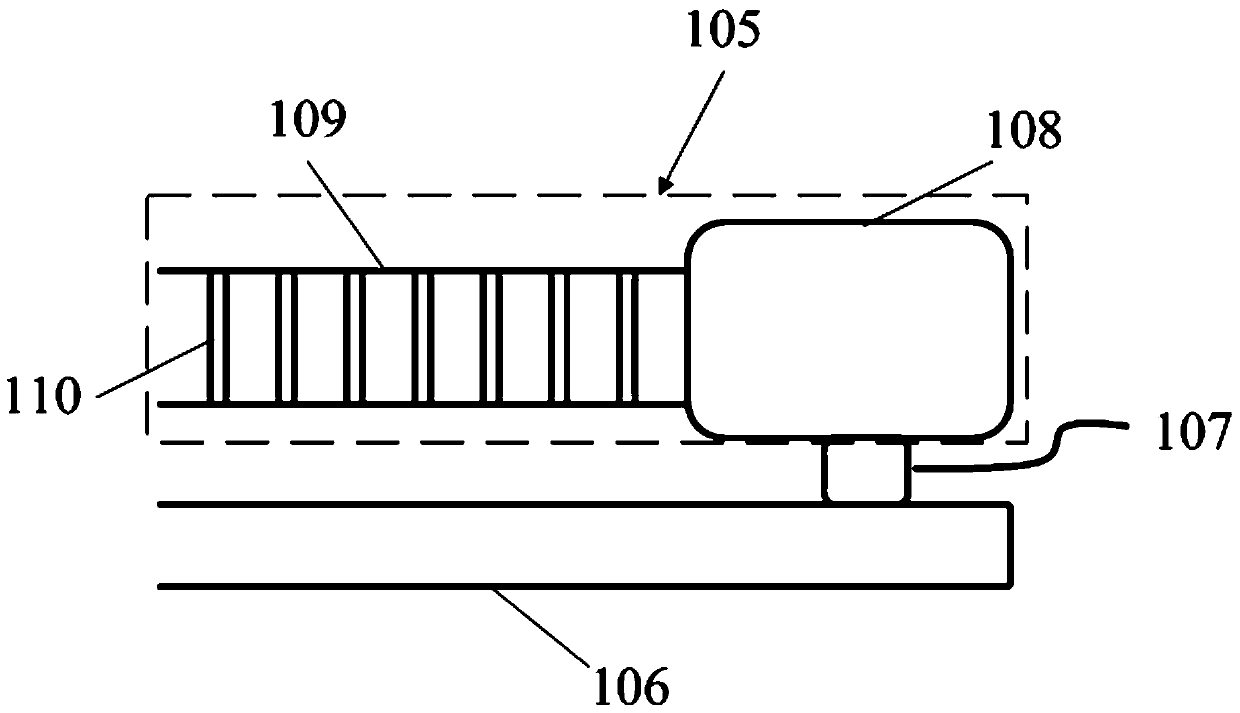

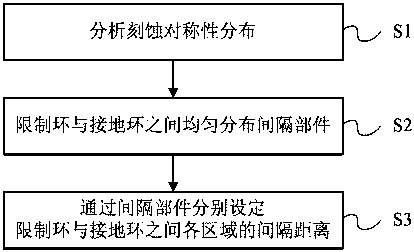

[0029] Such as figure 1 As shown, Embodiment 1 of a plasma processing device for improving etching symmetry is disclosed. The plasma processing device includes a plasma reaction chamber 101. The shape of the plasma reaction chamber 101 is not limited to a cylindrical shape. Can be horn-shaped.

[0030] A base 104 for placing the wafer 102 is provided at the bottom of the plasma reaction chamber 101, and an electrostatic chuck 103 for absorbing the wafer 102, as well as a heater or refrigerant flow path, etc., can be provided in the base 104 as required. Temperature regulation mechanism, etc.

[0031] When performing plasma etching, the reaction gas is supplied to the plasma reaction chamber 101, and the corresponding upper electrode and the lower electrode are provided in the plasma reaction chamber 101, which are used to excite the reaction g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com