G-C3N4 photoelectric catalyst and preparation method thereof

A catalyst, g-c3n4 technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of complex preparation, low catalytic efficiency, and difficult recovery of photoelectric catalysts, and achieve simple preparation, Good catalytic effect, inhibition of recombination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] a g-C 3 N 4 The photocatalyst is prepared by the following steps:

[0023] S1. Transfer 20 ml of the prepared melamine (6 g / L) acetic acid solution to a two-electrode system, with a carbon rod as the cathode, and a 1×2 cm 2 The FTO conductive glass used as the anode was electroplated with the HDV-7C transistor potentiostat under the conditions of the temperature of the electroplating solution at 50 °C, the constant current at -0.5 mA, and the time of 60 min to obtain elemental melamine.

[0024] S2. Calcining the prepared melamine in a tube furnace at a temperature of 550 °C for 4 h, VN 2 / O 2 =4:1 to get the g-C 3 N 4 photocatalyst.

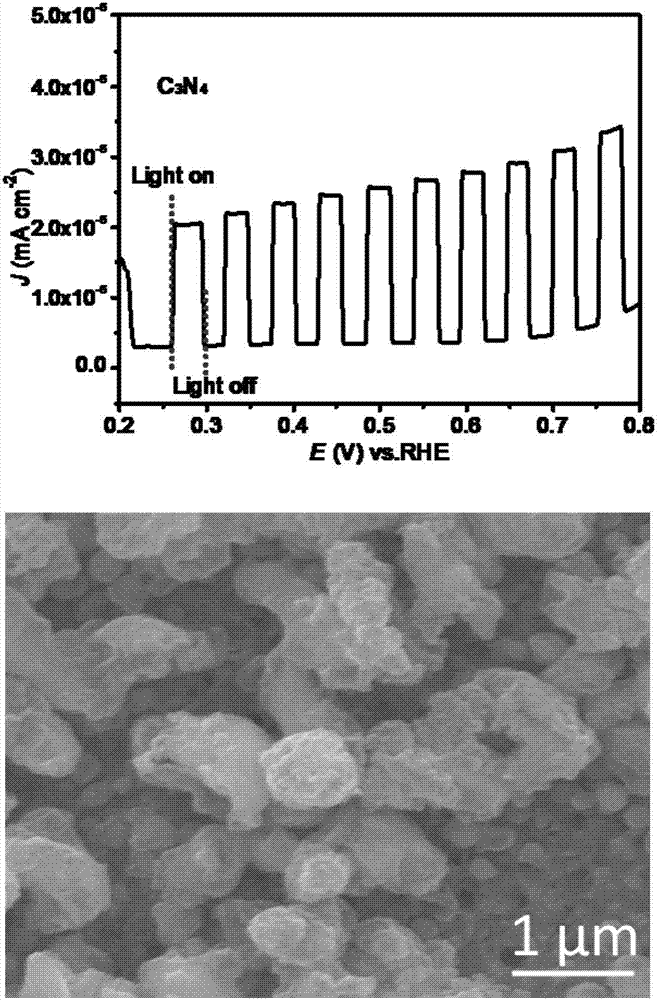

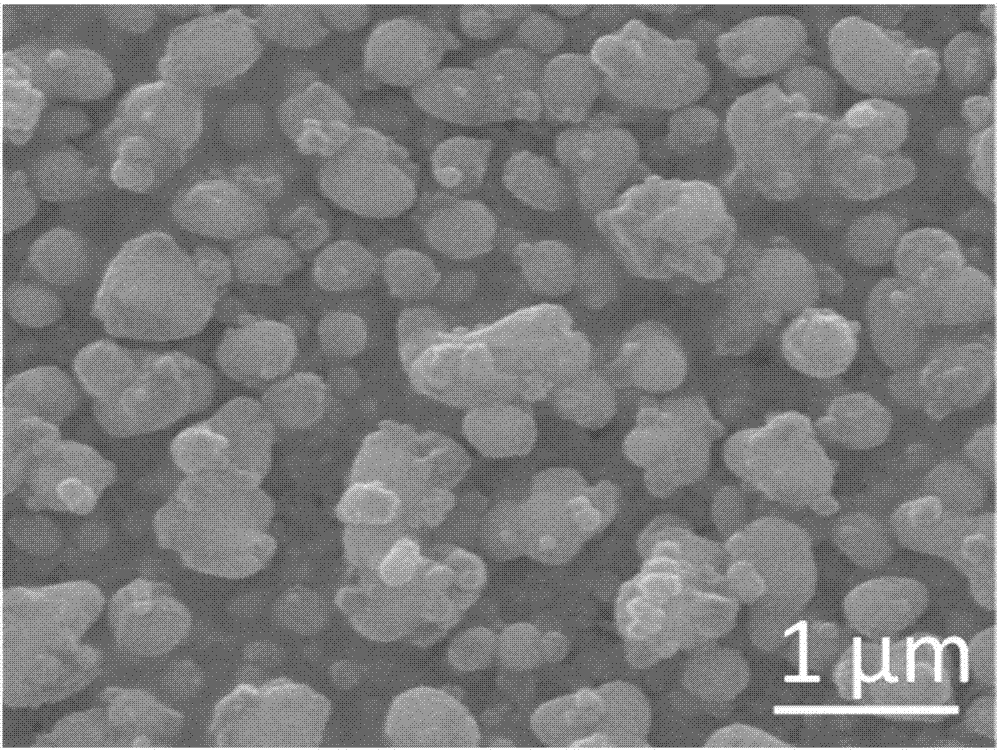

[0025] The g-C prepared in embodiment 1 3 N 4 Photoelectrocatalytic oxygen evolution map and SEM image figure 1 , the figure illustrates that our prepared g-C 3 N 4 It is in the form of nanoparticles and has good photoelectric catalytic oxygen evolution performance, and is an important catalytic material for photoelectric catal...

Embodiment 2

[0027] a g-C 3 N 4 The photocatalyst is prepared by the following steps:

[0028] S1. Transfer 20 ml of the prepared melamine (6 g / L) acetic acid solution to a two-electrode system, with a carbon rod as the cathode, and a 1×2 cm 2 The FTO conductive glass used as the anode was electroplated with the HDV-7C transistor potentiostat under the conditions of the temperature of the electroplating solution at 30 °C, the constant current of -0.5 mA, and the time of 30 min to obtain elemental melamine.

[0029] S2. Calcining the prepared melamine in a tube furnace at a temperature of 550 °C for 2 h, VN 2 / O 2 =4:1 to get the g-C 3 N 4 photocatalyst.

Embodiment 3

[0031] a g-C 3 N 4 The photocatalyst is prepared by the following steps:

[0032] S1. Transfer 20 ml of the prepared melamine (6 g / L) acetic acid solution to a two-electrode system, with a carbon rod as the cathode, and a 1×2 cm 2 The FTO conductive glass used as the anode was electroplated with a HDV-7C transistor potentiostat under the conditions of the temperature of the electroplating solution at 30 °C, the constant current at -2 mA, and the time of 60 min to obtain elemental melamine.

[0033] S2. Calcining the prepared melamine in a tube furnace at a temperature of 300 °C for 4 h, VN 2 / O 2 =2:1 to get the g-C 3 N 4 photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com