Aluminum alloy arc auxiliary coating additive manufacturing (AM) system and method

A technology of additive manufacturing and aluminum alloy, which is applied in the field of aluminum alloy arc-assisted coating additive manufacturing system, can solve the problems of low laser energy absorption rate, gaps between layers, and limited size, so as to improve the preparation efficiency and avoid Gaps, quality-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

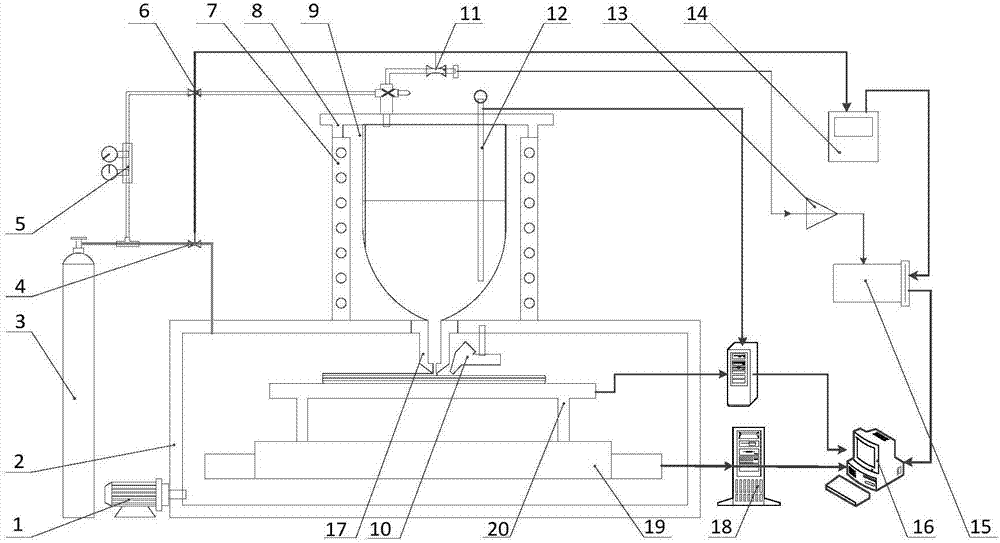

[0024] The present invention is described in further detail below in conjunction with accompanying drawing:

[0025] refer to figure 1 The aluminum alloy arc-assisted coating additive manufacturing system described in the present invention includes a closed glove box 2, a three-dimensional mobile platform 19, a substrate 20, a crucible 9, a coating head 17, an arc heat source 10, a power supply, a first gas supply system, The second gas supply system and controller 16; the crucible 9 is fixed on the closed glove box 2, the three-dimensional mobile platform 19, the substrate 20 and the arc heat source 10 are all located in the closed glove box 2, and the substrate 20 is located on the three-dimensional mobile platform 19, coating The upper end of the head 17 communicates with the bottom outlet of the crucible 9, the lower end of the coating head 17 is inserted into the closed glove box 2 and faces the substrate 20, the arc heat source 10 is fixed on the top of the closed glove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com