Hobbing cutter changing mechanical hand for large-diameter slurry shield machine

A technology of shield machine and large diameter, which is applied in the direction of manipulators, metal processing, metal processing equipment, etc., can solve problems affecting the reliability of equipment, and achieve the effects of saving manpower and economic costs, reliable work, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

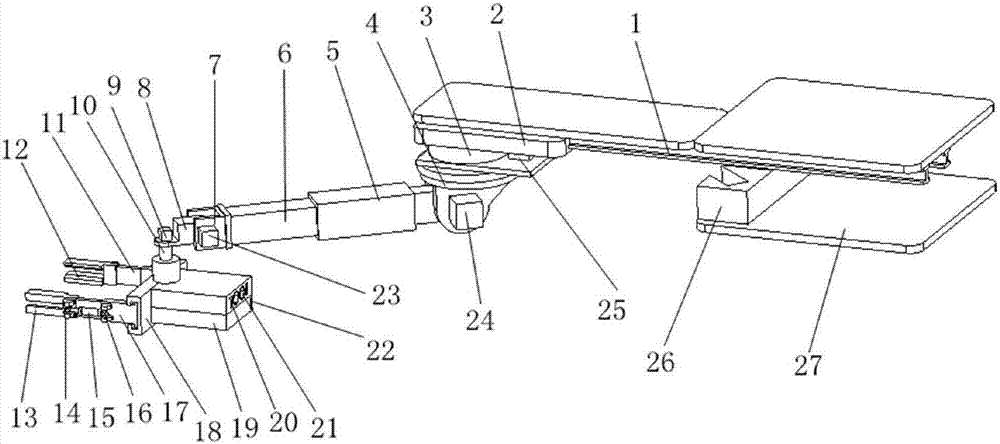

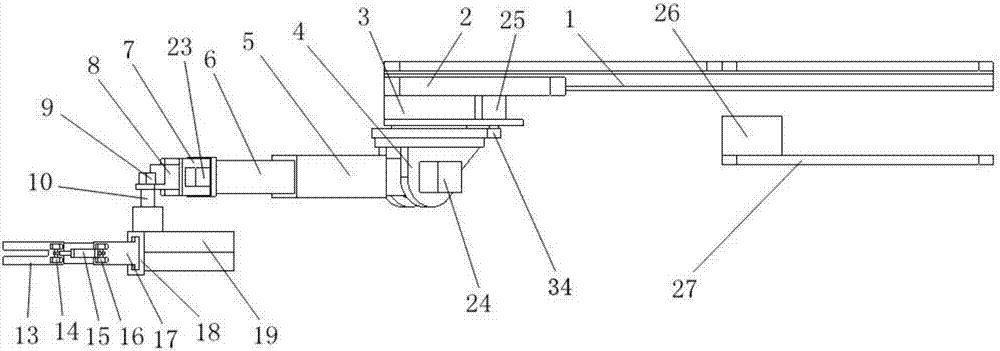

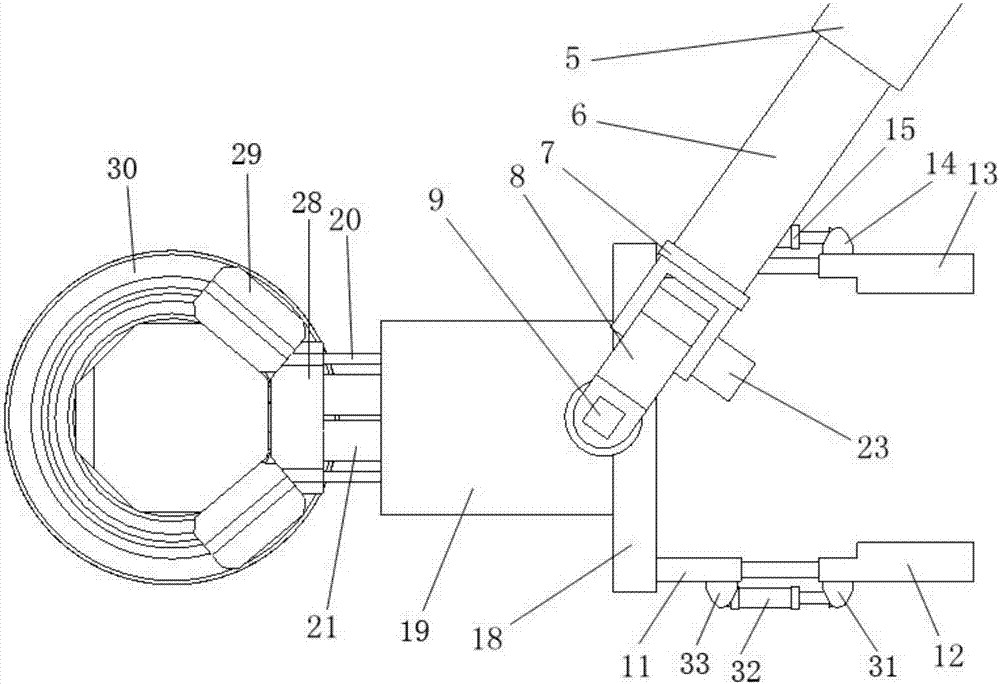

[0038] like figure 1 and figure 2 As shown, the large-diameter muddy water shield hob tool changing manipulator provided by the present invention includes a base, a mechanical telescopic arm, and a tool changing device; one end of the mechanical telescopic arm rotates with the base 2 through a first rotary drive mechanism connection; the first rotary drive mechanism includes a first hydraulic motor 25, a drive gear 34 and a slewing bearing 3; the output end of the first hydraulic motor 25 is connected to the drive gear 34; the outer ring of the slewing bearing 3 is connected to the The drive gear 34 is meshed and driven to drive the mechanical telescopic arm connected to it for linkage; the tool changer includes a housing 19, a bolt disassembly module, a wedge disassembly module, a pressure block disassembly module and a hob disassembly modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com