Halogen-free flame-retardant polycarbonate material and preparation method thereof

A technology of flame retardant polycarbonate and polycarbonate resin, applied in the field of polycarbonate modified materials, can solve problems such as gaps, and achieve the effects of good processability, excellent transparency and high impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

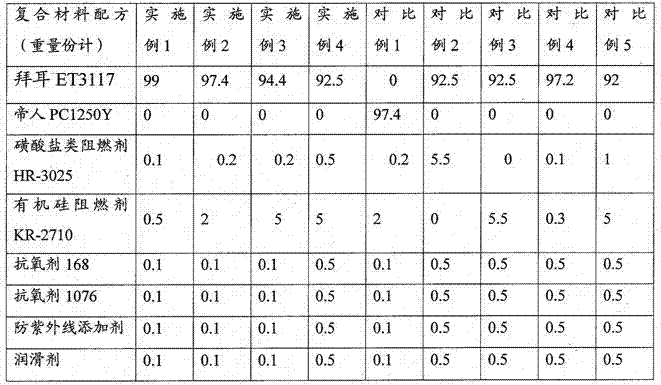

[0028] Embodiment 1, the preparation of halogen-free flame-retardant polycarbonate material

[0029] The following components in parts by weight: 97.4 parts of ET3117, 0.2 parts of sulfonate flame retardant HR-3025, 2 parts of silicone flame retardant KR-2710, 0.1 part of antioxidant 168, 0.1 part of antioxidant Agent 1076, 0.1 part of lubricant, 0.1 part of anti-ultraviolet additive are mixed in a high-speed mixer for 3 minutes, then extruded through a twin-screw extruder at 260-280 ° C, cooled, and pelletized, and the resulting pellets are dried at 120 ° C After 4 hours, it is injected into a standard spline at 260-280°C to obtain

Embodiment 2

[0030] Embodiment 2, the preparation of halogen-free flame-retardant polycarbonate material

[0031] The following components in parts by weight: 99 parts of ET3117, 0.1 part of sulfonate flame retardant HR-3025, 0.5 part of silicone flame retardant KR-2710, 0.1 part of antioxidant 168, 0.1 part of antioxidant Agent 1076, 0.1 part of lubricant, 0.1 part of anti-ultraviolet additive are mixed in a high-speed mixer for 3 minutes, then extruded through a twin-screw extruder at 260-280 ° C, cooled, and pelletized, and the resulting pellets are dried at 120 ° C After 4 hours, it is injection molded into a standard spline at 260-280°C, and it is ready.

Embodiment 3

[0032] Embodiment 3, the preparation of halogen-free flame-retardant polycarbonate material

[0033] The following components in parts by weight: 94.4 parts of ET3117, 0.2 parts of sulfonate flame retardant HR-3025, 5 parts of silicone flame retardant KR-2710, 0.1 part of antioxidant 168, 0.1 part of antioxidant Agent 1076, 0.1 part of lubricant, 0.1 part of anti-ultraviolet additive are mixed in a high-speed mixer for 3 minutes, then extruded through a twin-screw extruder at 260-280 ° C, cooled, and pelletized, and the resulting pellets are dried at 120 ° C After 4 hours, it is injected into a standard spline at 260-280°C to obtain

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com