Unpowered rainfall runoff pollutant intercepting facility and pollutant intercepting operation method

A pollutant and rainwater technology, applied in water/sludge/sewage treatment, drainage structures, water/sewage treatment, etc., to achieve the effect of improving effluent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

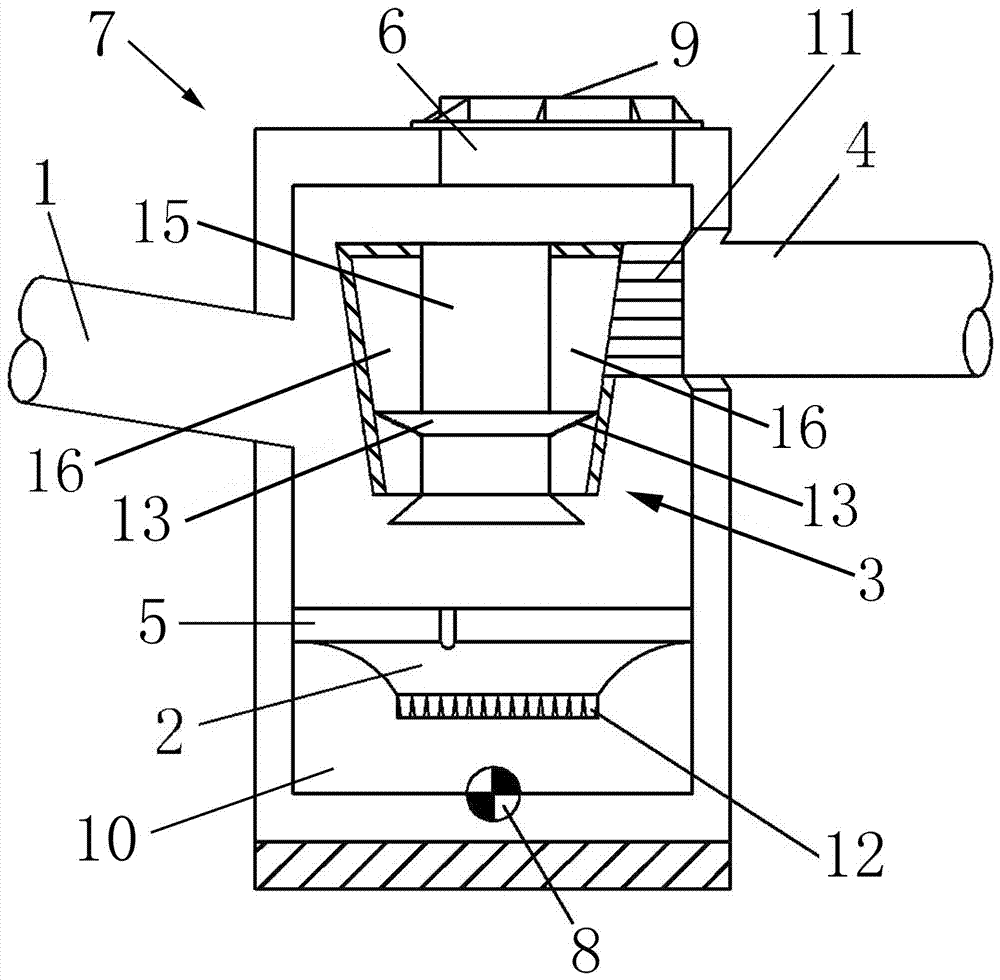

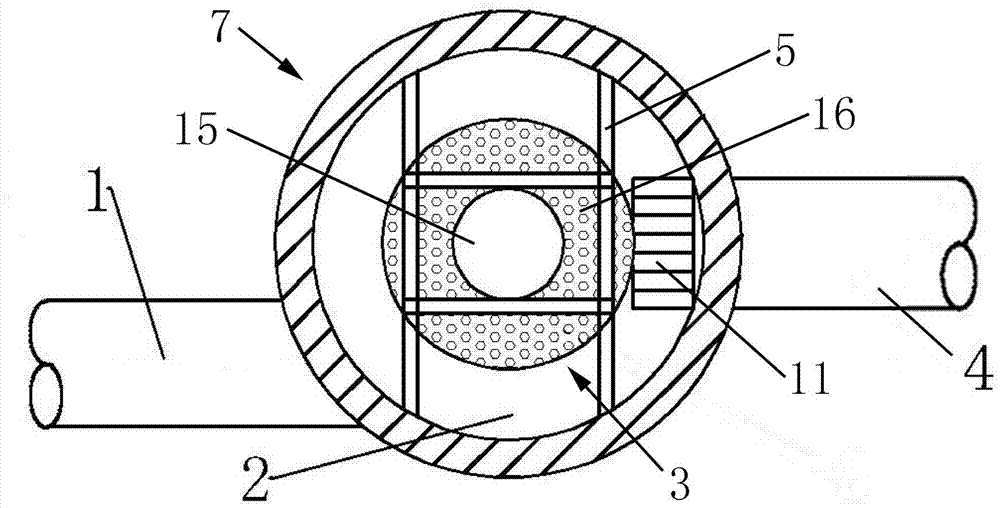

[0024] It consists of the main body of the facility (7), the water inlet pipe (1), the water outlet pipe (4), the guide tube (3), the guide plate (2), the sediment collection area (10), the water outlet collection port (11), the slag discharge The main body of the facility (7) is barrel-shaped as a whole, and the main body of the facility (7) is made of cement products, cast iron or modified plastic materials, and water inlet pipes (1) are arranged on both sides of the upper part of the main body of the facility (7). and the water outlet pipe (4), the water inlet pipe (1) and the water outlet pipe (4) are connected with the main body (7) of the facility, the water inlet pipe (1) and the water outlet pipe (4) are made of metal or modified plastic material, and the facility The water inlet pipe (1) is installed on one side of the main body (7), and the water inlet pipe (1) is inserted into the facility main body (7) at an oblique angle, and the water inlet pipe (1) is inserted in...

Embodiment 2

[0026] A support frame (5) is set in the middle of the main body (7) of the facility, and the support frame (5) is in the shape of a well as a whole, and a guide tube (3) is installed on the support frame (5), and the guide tube (3) is in the shape of a barrel as a whole , the guide tube (3) is made of metal material or modified plastic material, the guide tube (3) is composed of the guide tube inner tube (15) and the guide tube outer tube (16), the guide tube outer tube (16 ) barrel, the whole is a blind hole, the inner tube of the guide tube (15) is packed in a barrel, and the whole is a through hole, one end of the inner tube of the guide tube (15) passes through the upper end of the outer tube of the guide tube (16), and the guide tube The other end of the inner tube of the flow tube (15) passes through the lower end of the outer tube of the flow guide tube (16), and the top end of the other end of the inner tube of the flow guide tube (15) is funnel-shaped, and the top of ...

Embodiment 3

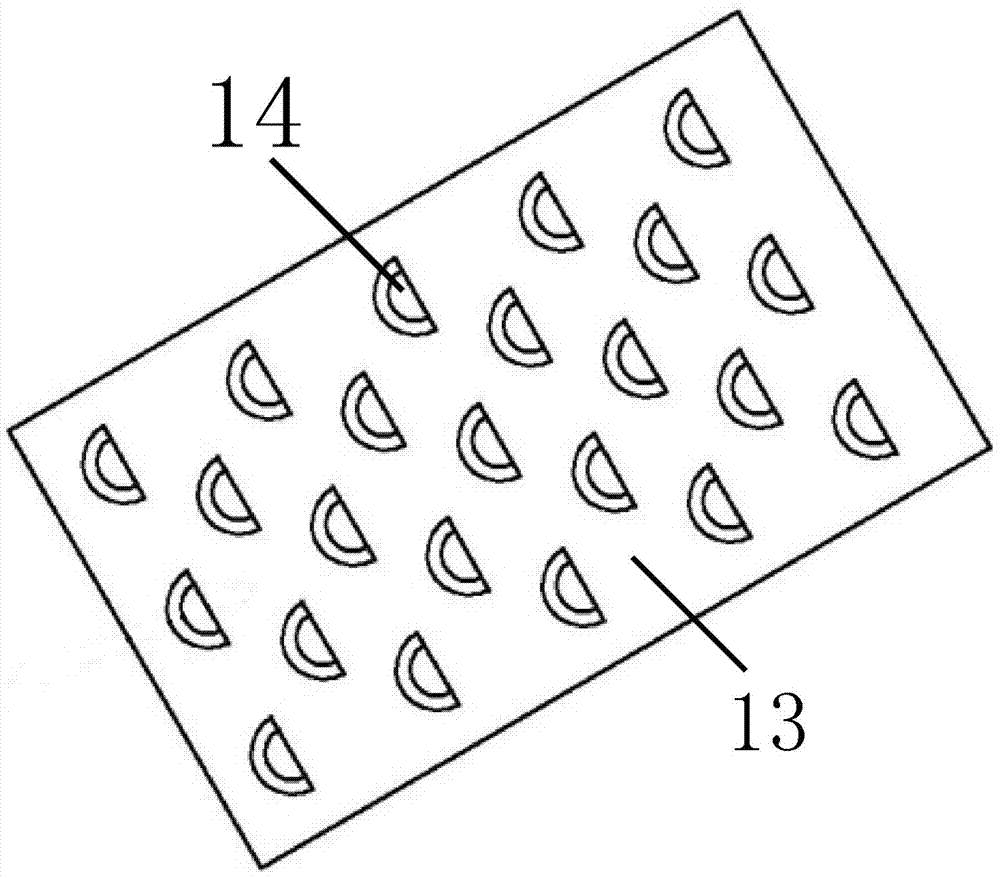

[0029] The rainwater passes through the filter screen (13) during the rising process, and the residual pollutants are intercepted. The rainwater passes through the sieve holes (14) of the filter screen (13) and swirls up in the outer cylinder (16) of the diversion cylinder. The other side of the main body (7) is provided with a water outlet pipe (4), and one end of the water outlet pipe (4) is provided with a water outlet collection port (11). 18) is fixedly connected to the cylinder wall, and one end of the water outlet pipe (4) is provided with a water outlet collection port (11), and the water outlet collection port (12) is connected with the upper part of the diversion outer cylinder (18), and passes through the filter screen (13 ) through the water outlet collection port (11) to collect the rainwater in the diversion outer cylinder (18), and the separated rainwater flows into the outlet pipe (4) to be discharged. The cover plate (9) can carry out inspection or maintenance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com