Device and method suitable for treating drilling cleaning production waste along with drilling without falling to ground

A clean production and waste technology, applied in the direction of earthwork drilling, flushing wellbore, wellbore/well parts, etc., can solve the problems of less equipment and cannot meet production needs, and achieve the effect of high practicability and guaranteed transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

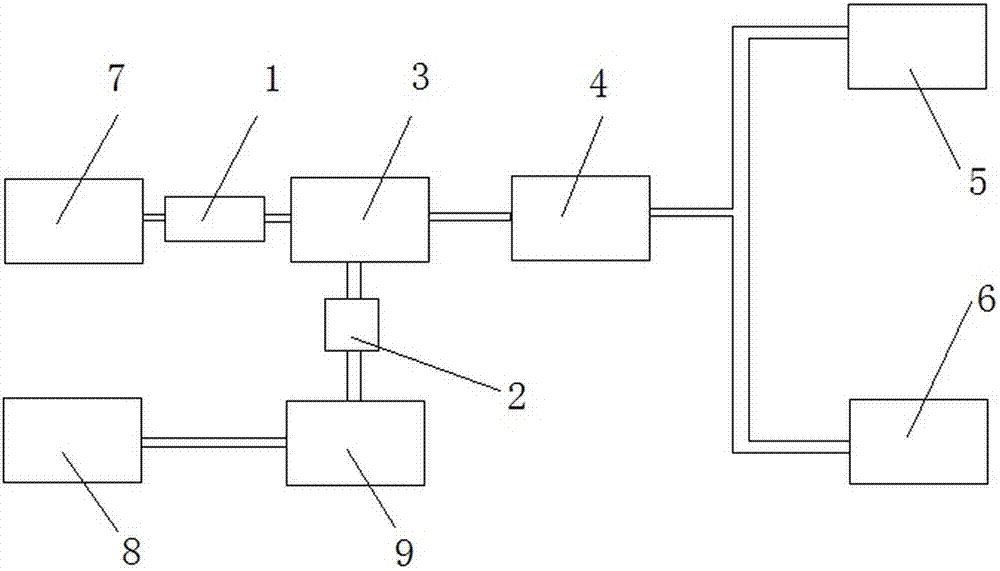

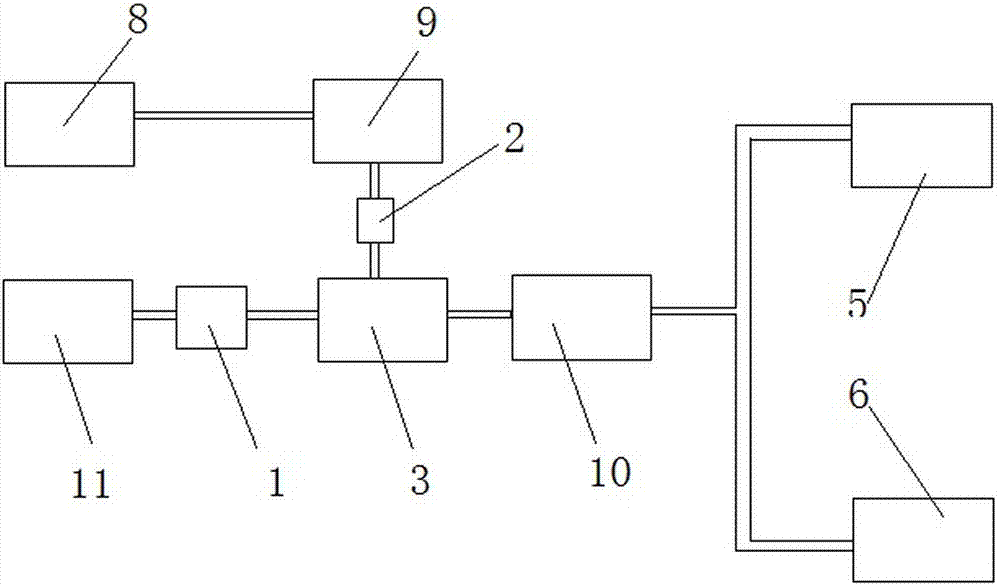

[0031] Such as Figure 1 to Figure 2 , a device suitable for processing drilling cleaning production waste without falling to the ground while drilling, characterized in that it includes an end to be cleaned, a screw conveyor 1 and / or a screw pump 2, and a cuttings pipeline transportation device 3 sequentially connected by a conveying pipeline , stirring tank 4 and / or solid-liquid phase separation device 10, the rear end of stirring tank 4 and / or solid-liquid phase separation device 10 is respectively connected with solid treatment area 6 and recycling pipeline 5; The phase separation device 10 includes a liquid phase output port and a solid phase output port, the liquid phase output port sends the separated liquid phase material to the recycling pipeline 5, and the solid phase output port sends the separated solid phase material to the solid treatment District 6.

[0032] This is a most basic embodiment of the present invention. The screw conveyor 1 and / or the screw pump 2 ...

Embodiment 2

[0034] Such as Figure 1 to Figure 2, a device suitable for processing drilling cleaning production waste without falling to the ground while drilling, characterized in that it includes an end to be cleaned, a screw conveyor 1 and / or a screw pump 2, and a cuttings pipeline transportation device 3 sequentially connected by a conveying pipeline , stirring tank 4 and / or solid-liquid phase separation device 10, the rear end of stirring tank 4 and / or solid-liquid phase separation device 10 is respectively connected with solid treatment area 6 and recycling pipeline 5; The phase separation device 10 includes a liquid phase output port and a solid phase output port, the liquid phase output port sends the separated liquid phase material to the recycling pipeline 5, and the solid phase output port sends the separated solid phase material to the solid treatment Zone 6; the end to be cleaned includes one or more combinations of drilling solids control equipment 7, a dredging tank 8 with ...

Embodiment 3

[0037] Such as Figure 1 to Figure 2 , a device suitable for processing drilling cleaning production waste without falling to the ground while drilling, characterized in that it includes an end to be cleaned, a screw conveyor 1 and / or a screw pump 2, and a cuttings pipeline transportation device 3 sequentially connected by a conveying pipeline , stirring tank 4 and / or solid-liquid phase separation device 10, the rear end of stirring tank 4 and / or solid-liquid phase separation device 10 is respectively connected with solid treatment area 6 and recycling pipeline 5; The phase separation device 10 includes a liquid phase output port and a solid phase output port, the liquid phase output port sends the separated liquid phase material to the recycling pipeline 5, and the solid phase output port sends the separated solid phase material to the solid treatment Zone 6; the end to be cleaned includes one or more combinations of drilling solids control equipment 7, a dredging tank 8 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com