Push-rod high-power electromagnetic relay

An electromagnetic relay, high-power technology, applied in electromagnetic relays, electromagnetic relay details, relays, etc., can solve the problems of small electromagnetic system space, ablated contacts, and large contact reaction force, and increase insulation performance. , the effect of reducing the elastic coefficient and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

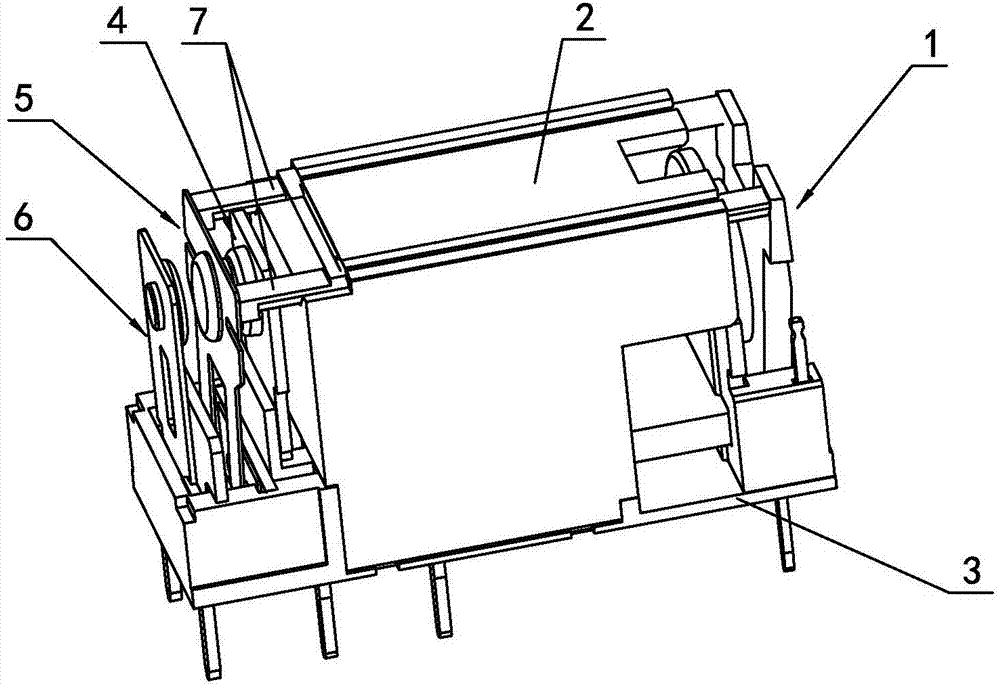

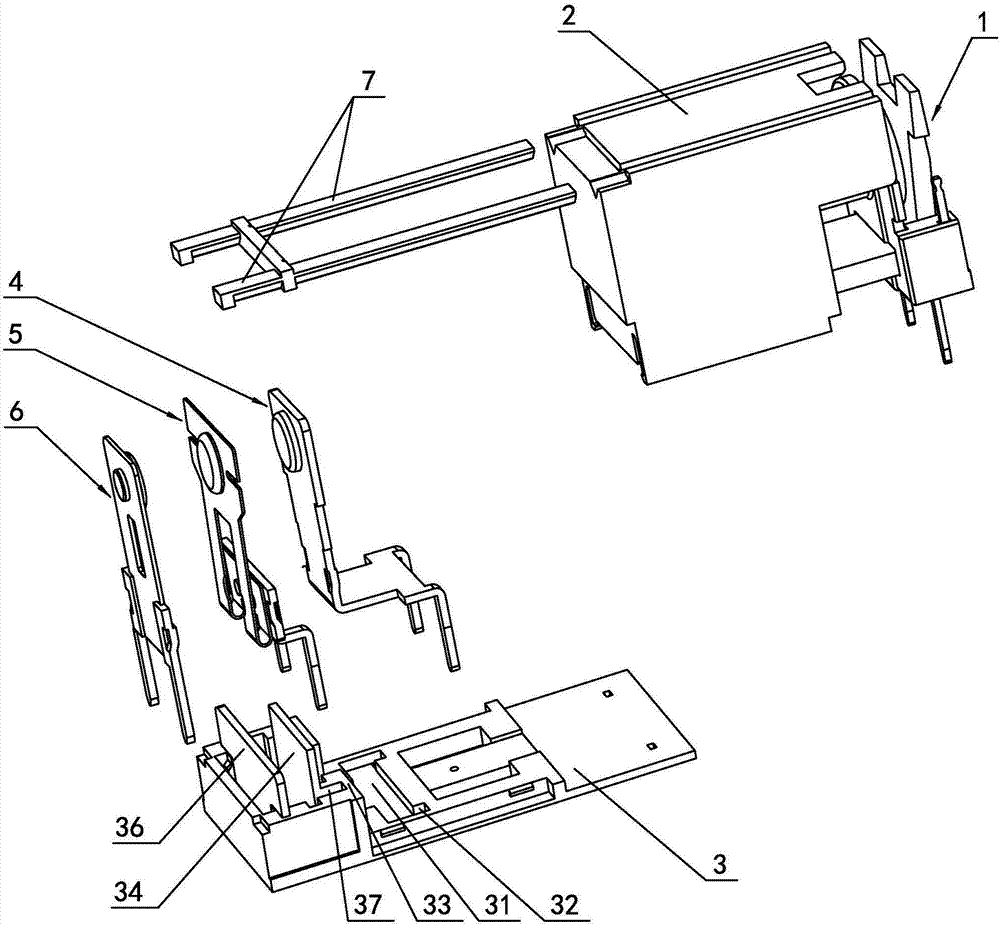

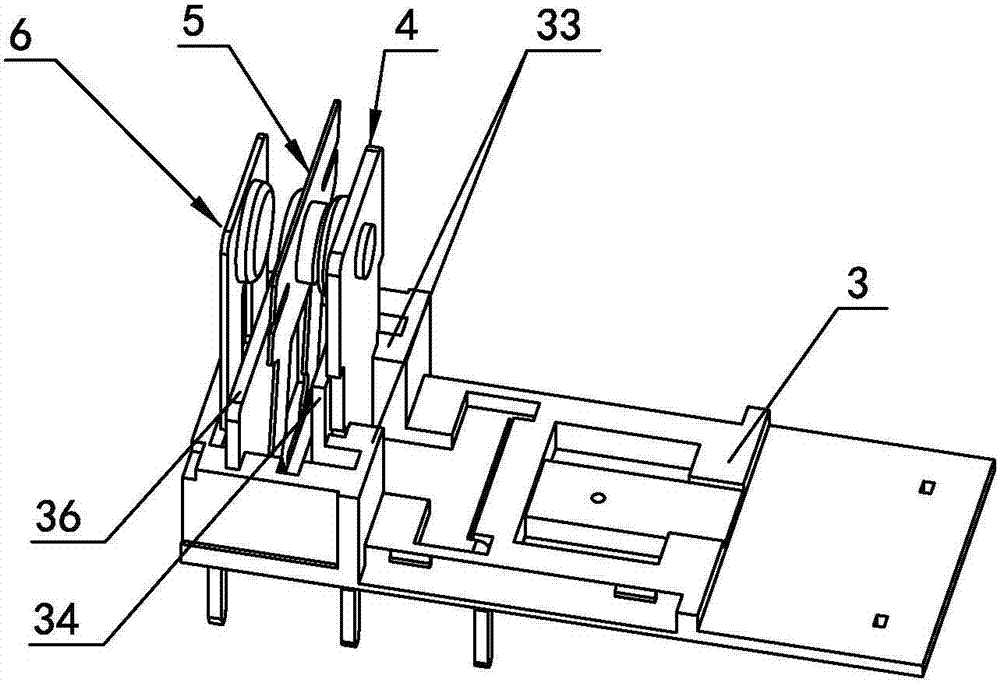

[0026] Embodiment one, such as Figure 1 to Figure 8 As shown, a push rod type high-power electromagnetic relay includes an electromagnetic system 1, an insulating cover 2, a base 3, and a normally closed static contact group 4 fixedly arranged on the base 3 from near to far from the electromagnetic system 1, The dynamic contact group 5 and the normally open static contact group 6, the electromagnetic system 1 is installed in the insulating cover 2, the normally closed static contact group 4 includes a static contact piece 41 and a normally closed static contact point 42 arranged on the upper part of the normally closed static contact piece 41 , the normally closed static contact piece 41 is a straight plate type, and its lower end is integrally provided with a first bending part 411 and two normally closed static lead-out pins 412 connected with the first bending part 411, and the dynamic contact group 5 includes an upper part provided with The movable reed 52 of the movable ...

Embodiment 2

[0029] Embodiment two, such as Figures 9 to 10 As shown, the technical features are the same as those in Embodiment 1, the difference is that the relay is a group of normally closed forms, that is, the normally open static contact piece 61 of the normally open static contact group 6 is not provided with a normally open static lead-out pin 63, and the normally open The material of static contact 62 also can be made of ordinary metal material instead of precious metal material, in addition, because of dustproof or sealing requirements, it also includes casing 8, and the bottom of base 3 is provided on two opposite sides below insulating cover 1. There are a plurality of small grooves 38, and the case 8 is fixedly connected to the base 3. The inner side wall of the case 8 and the small grooves 38 form a small slot 39. In this way, when the relay is in the sealing process, a small amount of glue is released from the small groove. The hole 39 flows in, so that the connection betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com