Lithium seawater battery and preparation method thereof

A seawater battery and lithium sheet technology, applied in the field of lithium seawater battery and its preparation, can solve the problems of water seepage, large difference in material properties, difficult to reflect high energy density, etc., and achieve good compatibility, stable structural properties, and structural properties. consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

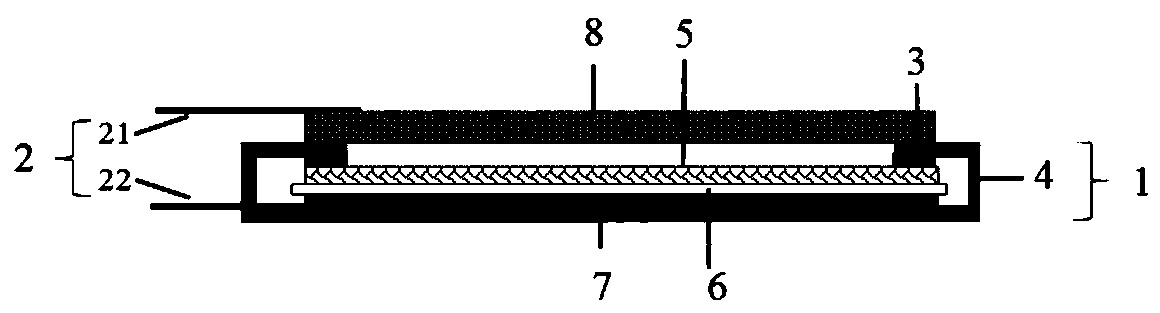

[0046] A lithium seawater battery of the present invention, such as figure 1 As shown, the lithium seawater battery includes a seawater positive electrode 8 and a lithium protected negative electrode 1 . The lithium protected negative electrode 1 is made of lithium sheet 7, diaphragm 6, and lithium ion solid electrolyte sheet 5 sealed in an aluminum-plastic packaging bag 4. The diaphragm 6 is soaked with electrolyte, and the aluminum-plastic packaging bag 4 is provided with a window, and the lithium ion solid The electrolyte sheet 5 seals the window on the aluminum-plastic packaging bag 4 through the packaging glue 3. The packaging glue 3 is high-density polyethylene tab glue with a density of 0.976 g / cm 3 .

[0047] In this embodiment, in the aluminum-plastic packaging bag 4 , the lithium-ion solid electrolyte sheet 5 , the separator 6 and the lithium sheet 7 are arranged in a laminated form, and the lithium-ion solid electrolyte sheet 5 and the lithium sheet 7 are separated...

Embodiment 2

[0072] A lithium seawater battery of the present invention, such as figure 1 As shown, the lithium seawater battery includes a seawater positive electrode 8 and a lithium protected negative electrode 1 . The lithium protected negative electrode 1 is made of lithium sheet 7, diaphragm 6, and lithium ion solid electrolyte sheet 5 sealed in an aluminum-plastic packaging bag 4. The diaphragm 6 is soaked with electrolyte, and the aluminum-plastic packaging bag 4 is provided with a window, and the lithium ion solid The electrolyte sheet 5 seals the window on the aluminum-plastic packaging bag 4 through the packaging glue 3, and the packaging glue 3 is a high-density polyethylene / polypropylene composite ear glue, wherein the high-density polyethylene / polypropylene composite ear glue is made of high-density polyethylene Composed of ethylene tab glue and high-density polypropylene tab glue, the high-density polypropylene tab glue is used as the middle structural support layer, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com