A kind of rare earth oxide coating and preparation method thereof

A technology of rare earth oxides and oxides, applied in the field of nano-functional coatings, to achieve the effects of easy industrial production, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Weigh 5 grams of cerium nitrate, add 2L of water and stir to obtain a transparent solution, then titrate and add 20 mL of 25% ammonia water, and stir for 30 minutes to obtain a colloidal solution of cerium hydroxide.

[0045] (2) Apply the above-mentioned colloidal solution on the surface of the cleaned glass by spraying to form a nanometer layer, and dry it under air conditions.

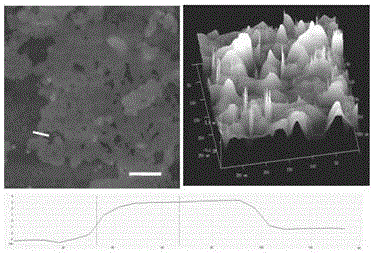

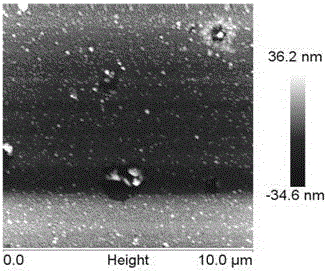

[0046] (3) Put the glass in (2) above into a muffle furnace, heat it at 450°C for 5 hours under air conditions, and cool it down to room temperature naturally to prepare a hydrophobic coating with a thickness of about 50 nanometers. figure 1 The atomic force microscope photo of the sample is shown. It can be seen from the photo that the hydrophobic coating on the glass surface is composed of cerium oxide nanoparticles with uniform size. The particle size is about 50 nanometers, and the grains are densely connected.

Embodiment 2

[0048] (1) Weigh 30 g of cerium acetate, add 5 L of water and stir to obtain a transparent solution, then titrate and add 100 mL of 25% ammonia water, and stir for 1 hour to obtain a colloidal solution of cerium hydroxide.

[0049] (2) Apply the above-mentioned colloidal solution to the surface of the cleaned ceramic sanitary ware by spraying to form a nanometer layer, and dry it under air conditions.

[0050] (3) Put the sanitary ware in (2) above into a tunnel kiln, heat at 700°C for 5 hours under air conditions, and cool naturally to room temperature to prepare a cerium oxide hydrophobic coating with a thickness of about 100 nanometers. figure 1 The atomic force microscope photo of the sample is shown. It can be seen from the photo that after heat treatment, a layer of hydrophobic coating composed of cerium oxide particles with a size of 30-100 nanometers is added to the surface of the substrate, and the thickness of the cerium oxide layer is about 100 nanometers. , The par...

Embodiment 3

[0052] (1) Weigh 15 grams of cerium oxide powder, add it to 1L of water and grind it to a particle size of 300 nanometers, and disperse it in water to obtain a translucent emulsion.

[0053] (2) Apply the above-mentioned emulsion on the surface of the cleaned alumina ceramics by inkjet printing, and dry under air conditions.

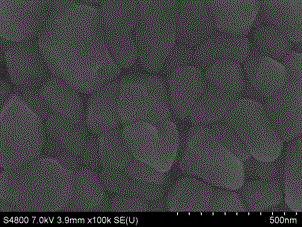

[0054] (3) Put the above-mentioned alumina ceramics in (2) into a roller kiln, heat-treat at 1200°C for 5 hours under air conditions, and form a 400-nanometer cerium oxide hydrophobic coating on the surface of the substrate after cooling to room temperature . The resulting coating was examined with a scanning electron microscope, as image 3 As shown in the figure, the size of the cerium oxide particles on the ceramic surface is about 400 nanometers, the particle size is uniform, and the particles are closely connected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com