Cold and hot integrated box body structure

A box structure, hot and cold technology, applied in structural parts, electrochemical generators, electrical components, etc., can solve the problems of increased costs, high process and assembly requirements, and high assembly requirements for liquid cooling systems and heating systems, and achieves savings. Procurement cost, strong design flexibility, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

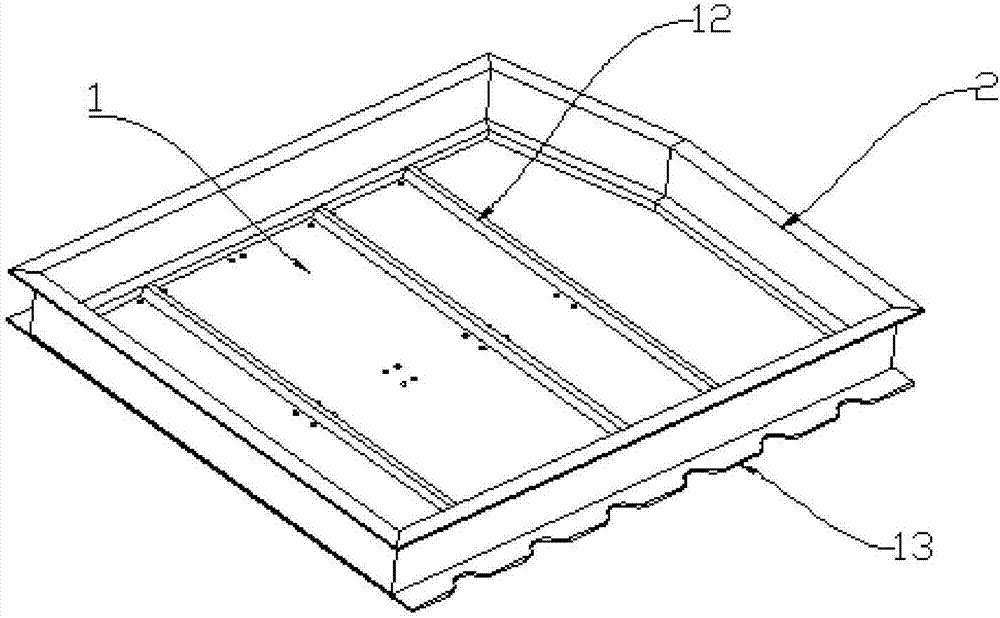

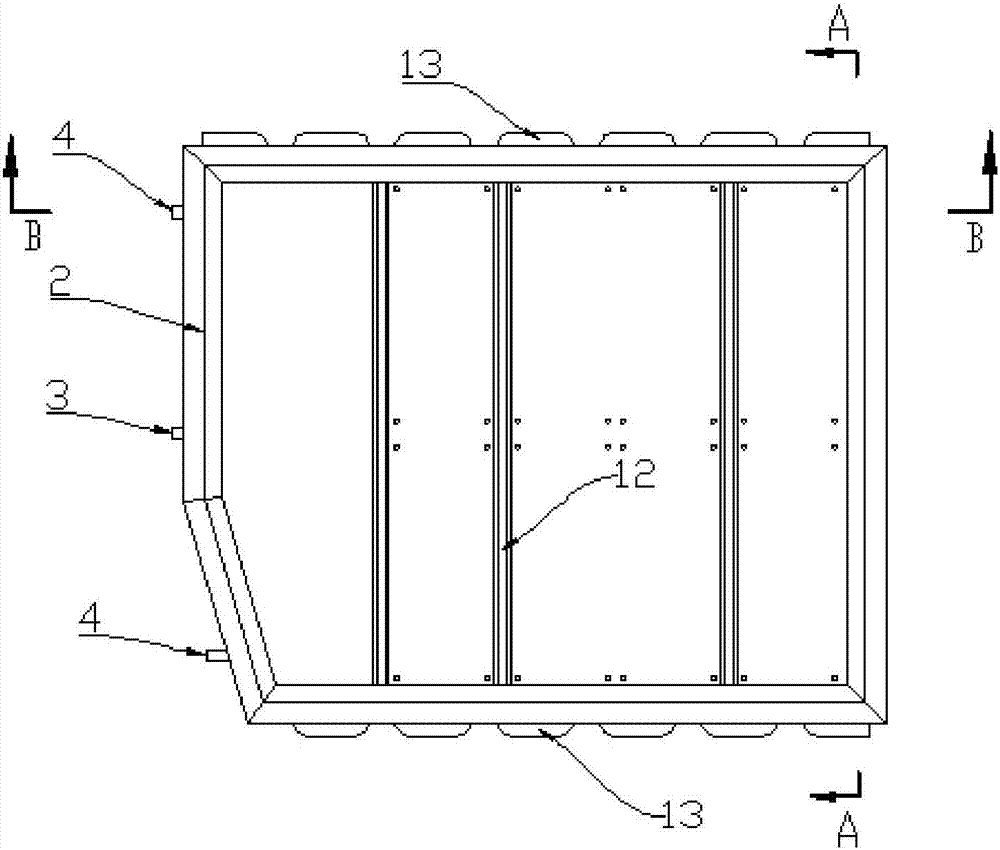

[0053] Such as Figure 1-7 As shown, the integrated cooling and heating box structure of this embodiment is a single-layer structure, specifically, as figure 1 As shown, the box structure includes a box body with an upper opening. The box body includes a bottom plate 1 and a side plate 2. The bottom plate 1 and the side plates 2 enclose a storage cavity for accommodating batteries. Inside the bottom plate 1 are alternately arranged liquid Cooling system and heating system.

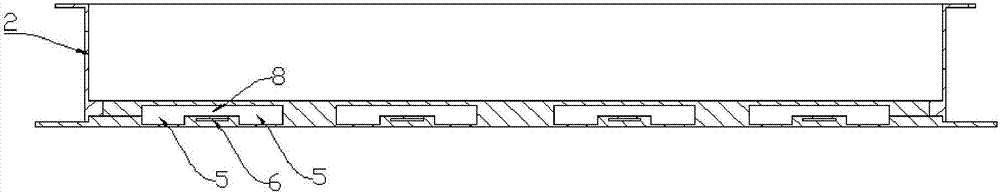

[0054] Such as figure 2 , Figure 4 and Figure 5 As shown, the side plate 2 is provided with a fluid inlet 3 and two fluid outlets 4 (one in and two out), which communicate with the liquid cooling system. The fluid inlet 3 is arranged in the middle of one side plate 2, and the two fluid outlets 4 It is symmetrically arranged at both ends of the side plate 2 . Such as Figure 6 As shown, the liquid cooling system is a coolant flow channel 5 distributed in a serpentine shape inside the bottom plate 1...

Embodiment 2

[0062] The integrated cooling and heating box structure of this embodiment is a double-layer structure (such as Figure 12 and Figure 13 shown), specifically, as Figure 8 As shown, the box structure includes a box body with an upper opening. The box body includes a bottom plate 1 and a side plate 2. The bottom plate 1 and the side plates 2 enclose a storage cavity for accommodating batteries. Inside the bottom plate 1 are alternately arranged liquid Cooling system and heating system.

[0063] Such as Figure 14 and Figure 15 As shown, the side plate 2 is provided with a fluid inlet 3 and two fluid outlets 4 (one in and two out), which communicate with the liquid cooling system. The fluid inlet 3 is arranged in the middle of one side plate 2, and the two fluid outlets 4 It is symmetrically arranged at both ends of the side plate 2 . Such as Figure 6 As shown, the liquid cooling system is a coolant flow channel 5 distributed in a serpentine shape inside the bottom plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com