A kind of positive electrode slurry, its preparation method and application

A positive electrode slurry and positive electrode technology, applied in the field of electrochemical materials, can solve the problems of low solid content of slurry, high cost, long stirring time, etc., and achieve the effects of improving baking efficiency, reducing dosage, and improving coating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

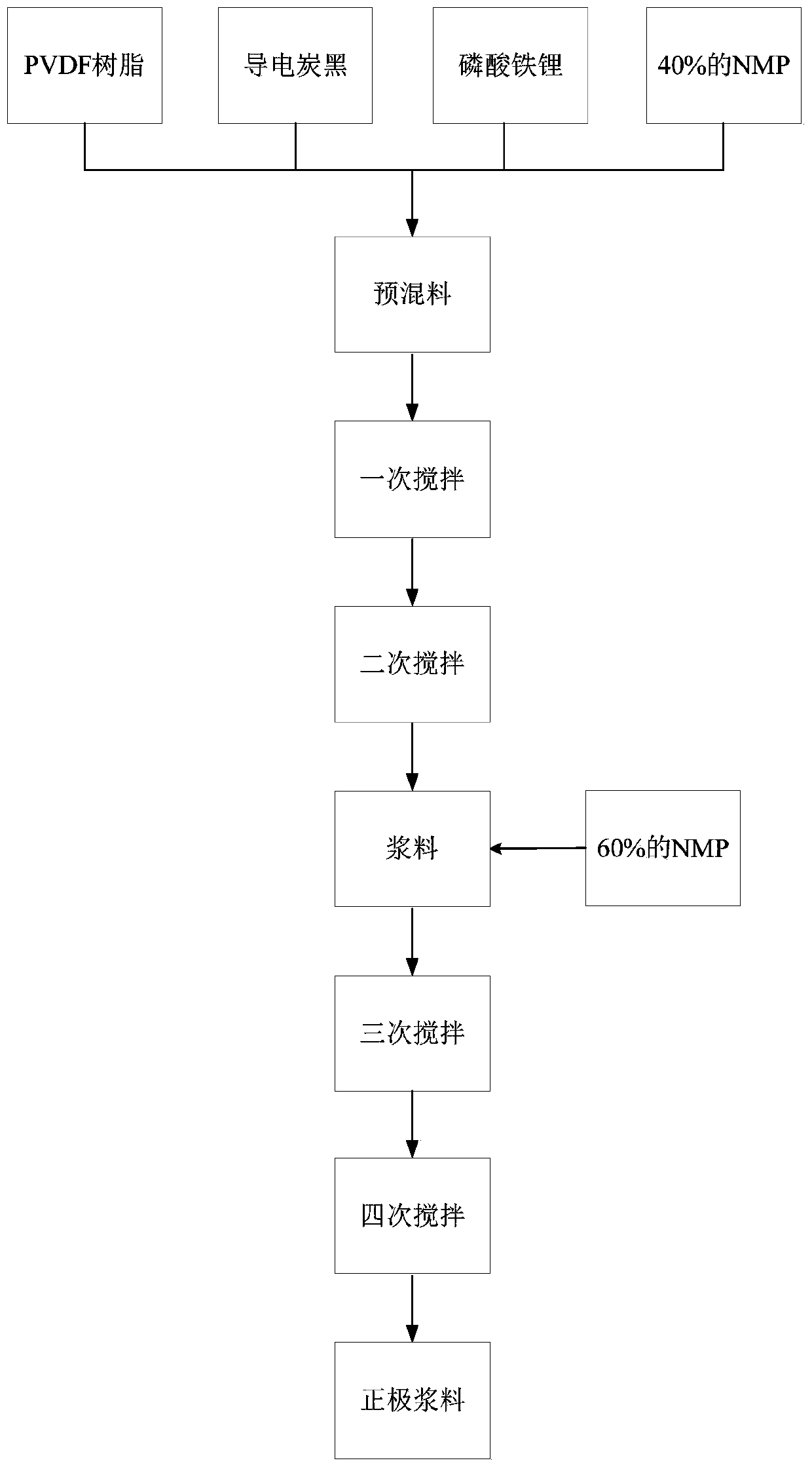

[0048] This embodiment provides a method for preparing positive electrode slurry (for the process flow chart, see figure 1 ), including the following steps:

[0049] (1) 2g PVDF resin, 3g conductive carbon black and 95g lithium iron phosphate are mixed with the NMP of 21.54g (the NMP used here accounts for 40% of the total NMP) to obtain a premix;

[0050] (2) The premixed material obtained in step (1) was first stirred for 15 minutes under the condition of 15 rpm of revolution and 500 rpm of rotation, and then stirred for 90 minutes for the second time under the condition of 25 rpm of revolution and 1000 rpm of rotation;

[0051] (3) Add the remaining 32.30g of NMP (the NMP used here accounts for 60% of the total NMP), and stir for 60 minutes three times under the conditions of revolution 25rpm and rotation 1200rpm;

[0052] (4) Stir the slurry obtained in step (3) four times for 30 minutes under the condition of only turning on the revolution at 10 rpm and not turning on the ...

Embodiment 2

[0055] This embodiment provides a method for preparing positive electrode slurry, comprising the following steps:

[0056] (1) 3g PVDF resin, 3g conductive carbon black and 94g lithium iron phosphate are mixed with the NMP of 18.85g (the NMP used here accounts for 35% of the total NMP) to obtain a premix;

[0057] (2) The premix obtained in step (1) was first stirred for 15 minutes under the conditions of revolution 12rpm and rotation 550rpm, and then secondly stirred for 90min under the conditions of revolution 28rpm and rotation 1050rpm;

[0058] (3) Add the remaining 35g of NMP (the NMP used here accounts for 65% of the total NMP), and stir three times for 60min under the conditions of revolution 20rpm and autorotation 1250rpm, to obtain positive electrode slurry.

[0059] The positive electrode was prepared by using the positive electrode slurry in this embodiment: the positive electrode slurry was first passed through a 150-mesh sieve, and then coated, and the coating pro...

Embodiment 3

[0061] This embodiment provides a method for preparing positive electrode slurry, comprising the following steps:

[0062] (1) 3g PVDF resin, 2.5g conductive carbon black and 94.5g lithium iron phosphate are mixed with 19.29g of NMP (the NMP used here accounts for 45% of the total NMP) to obtain a premix;

[0063] (2) The premix obtained in step (1) was first stirred for 15 minutes under the conditions of revolution 15rpm and autorotation 600rpm, and then secondly stirred for 90min under the conditions of revolution 30rpm and autorotation 1000rpm;

[0064] (3) Add the remaining 23.57g of NMP (the NMP used here accounts for 55% of the total NMP), and stir for 60 minutes three times under the conditions of revolution 22rpm and rotation 1280rpm;

[0065] (4) Stir the slurry obtained in step (3) four times for 30 minutes under the condition of only turning on the revolution at 10 rpm and not turning on the rotation, to obtain the positive electrode slurry.

[0066] The positive e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com