Stable mycophenolate mofetil for injection, and preparation method thereof

A technology of mycophenolate mofetil and water for injection, which is applied in the field of mycophenolate mofetil for injection and its preparation, can solve the problems of accelerated degradation and unstable storage of mycophenolate mofetil for injection, and avoid The effect of reducing curative effect, convenient operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

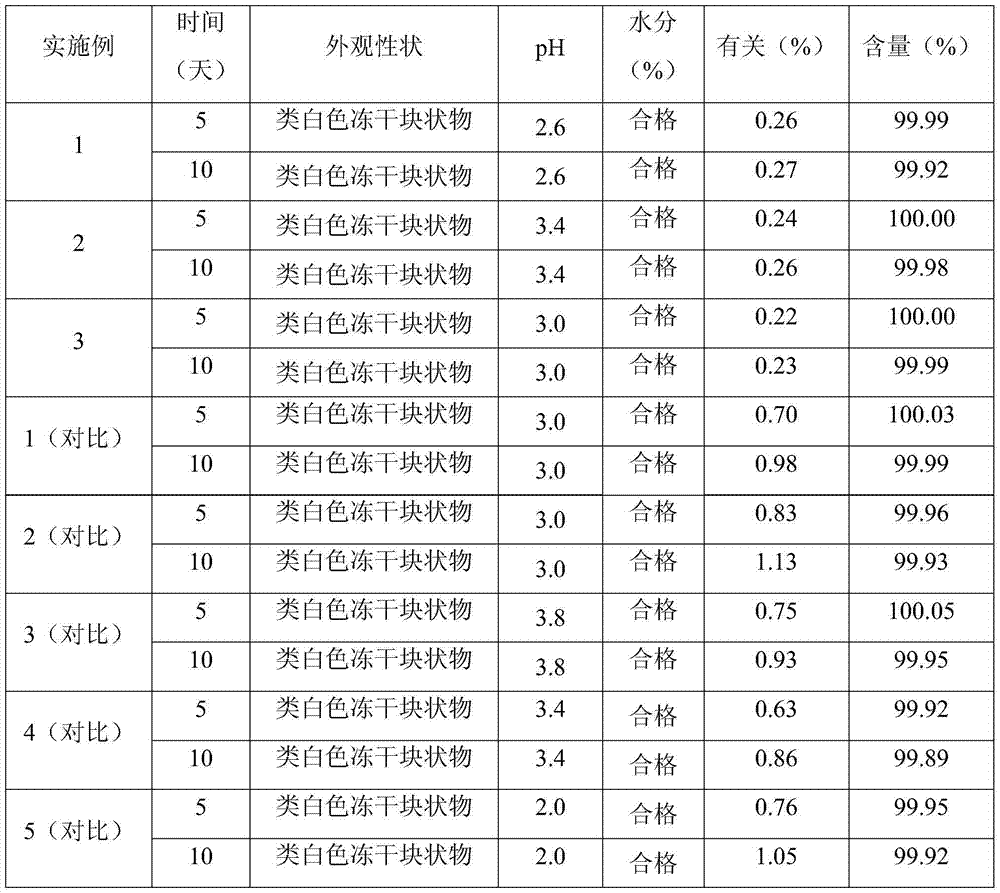

Examples

Embodiment 1

[0023] Add 2000ml of water for injection pre-cooled to room temperature into the dispensing tank, add 250.0g of mycophenolate mofetil, 2.5g of citric acid, and 8012.5g of polysorbate in the prescribed amount, stir and mix well, and adjust the pH of the solution with 1M hydrochloric acid to 3.4. Add 30.0 g of disodium tetraborate, set the volume to 2500 ml, stir the solution until it becomes a colorless clear liquid; filter, fill, freeze-dry, and visually inspect to obtain the finished product.

[0024] The freeze-drying process is:

[0025] Pre-freezing: Raise the temperature of the slab to 30°C and keep it warm for 30 minutes; then lower the temperature of the slab to -45°C in 210 minutes and keep it warm for 390 minutes;

[0026] Sublimation drying: pump the vacuum in the box to 80mTorr, and keep it at -35°C for 30 minutes; use 150 minutes to raise the temperature of the plate layer to -17.5°C, and hold it for 540 minutes;

[0027] Re-drying: take 150 minutes to raise the t...

Embodiment 2

[0029] Add 2000ml of water for injection pre-cooled to room temperature into the dispensing tank, add 250.0g of mycophenolate mofetil, 2.5g of citric acid, and 8012.5g of polysorbate in the prescribed amount, stir and mix well, and adjust the pH of the solution with 1M hydrochloric acid to 3.4, add 50.0 g of disodium tetraborate, set the volume to 2500 ml, stir the solution until it becomes a colorless clear liquid; filter, fill, freeze-dry, and visually inspect to obtain the finished product.

[0030] The freeze-drying process is:

[0031] Pre-freezing: Raise the temperature of the slab to 40°C and keep it warm for 40 minutes; then lower the temperature of the slab to -35°C in 270 minutes and keep it warm for 450 minutes;

[0032] Sublimation drying: pump the vacuum in the box to 120mTorr, and keep it at -35°C for 90 minutes; take 210 minutes to raise the temperature of the plate layer to -12.5°C, and hold it for 660 minutes;

[0033] Re-drying: take 210 minutes to raise the...

Embodiment 3

[0035] Add 2000ml of water for injection pre-cooled to room temperature into the dispensing tank, add 250.0g of mycophenolate mofetil, 2.5g of citric acid, and 8012.5g of polysorbate in the prescribed amount, stir and mix well, and adjust the pH of the solution with 1M hydrochloric acid to 3.0, add 40.0g of disodium tetraborate, set the volume to 2500ml, stir the solution to a colorless and clear liquid; filter, fill, freeze-dry, and visually inspect to obtain the finished product.

[0036] The freeze-drying process is:

[0037] Pre-freezing: Raise the temperature of the slab to 35°C and keep it warm for 35 minutes; then use 240 minutes to lower the temperature of the slab to -40°C and hold it for 420 minutes;

[0038] Sublimation drying: pump the vacuum in the box to 100mTorr, and keep it at -40°C for 60 minutes; use 180 minutes to raise the temperature of the plate layer to -15°C, and hold it for 600 minutes;

[0039] Re-drying: take 180 minutes to raise the temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com